Tsis Siv Neeg Infrared BGA Rework Chaw Nres Tsheb

1.Automatic BGA Rework chaw nres tsheb rau desoldering thiab soldering

2. Built-in infrared cua sov raj.

3. PID kub tswj thiab 3- thaj chaw cua sov ua haujlwm ua ke.

Hauj lwm lawm

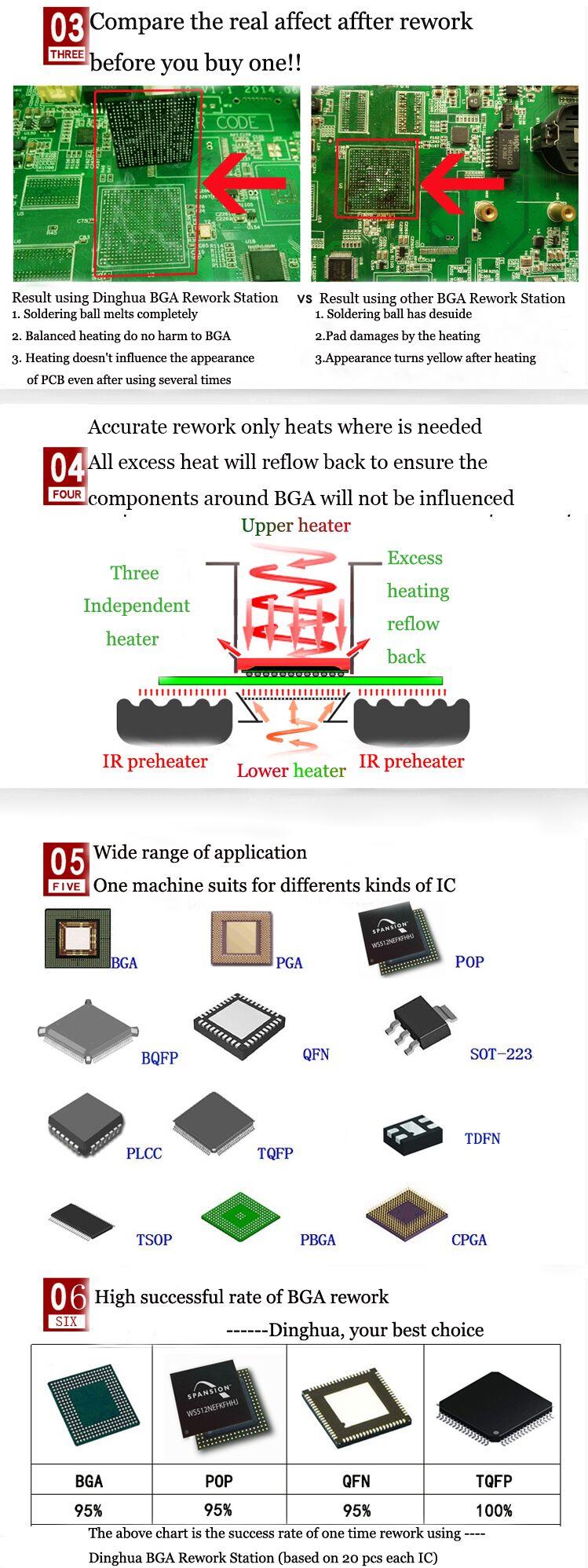

1. Daim ntawv thov ntawm

Solder, reball, desoldering ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP,

PBGA, CPGA, LED nti.

2.Advantage ntawm Tsis Siv Neeg Infrared BGA Rework chaw nres tsheb

3.Technical cov ntaub ntawv ntawm laser positioning

| zog | 5300W |

| Lub tshuab cua sov sab saum toj | Cua kub 1200W |

| Hauv qab rhaub | Cua kub 1200W.Infrared 2700W |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | K hom thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGAchip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

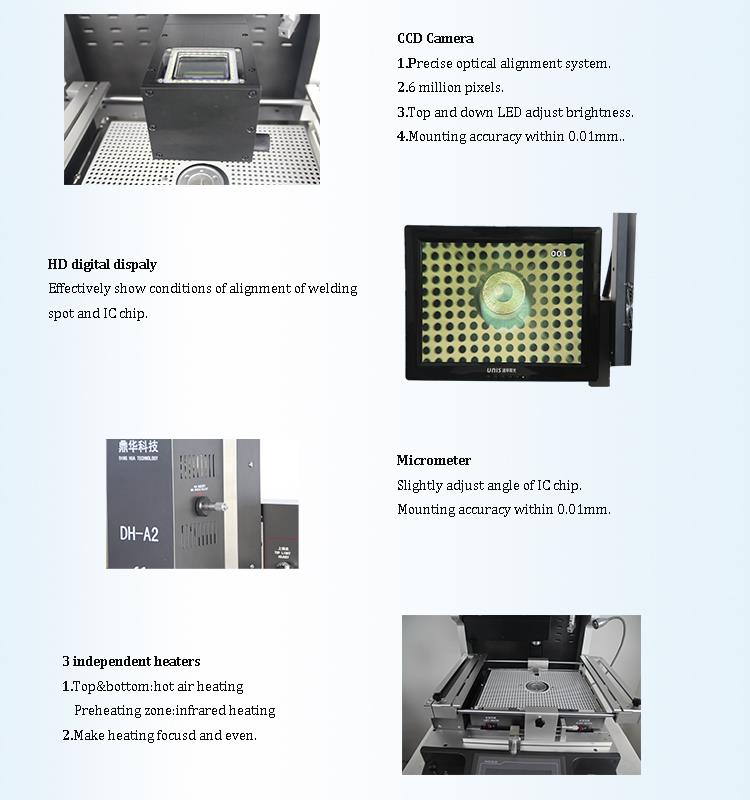

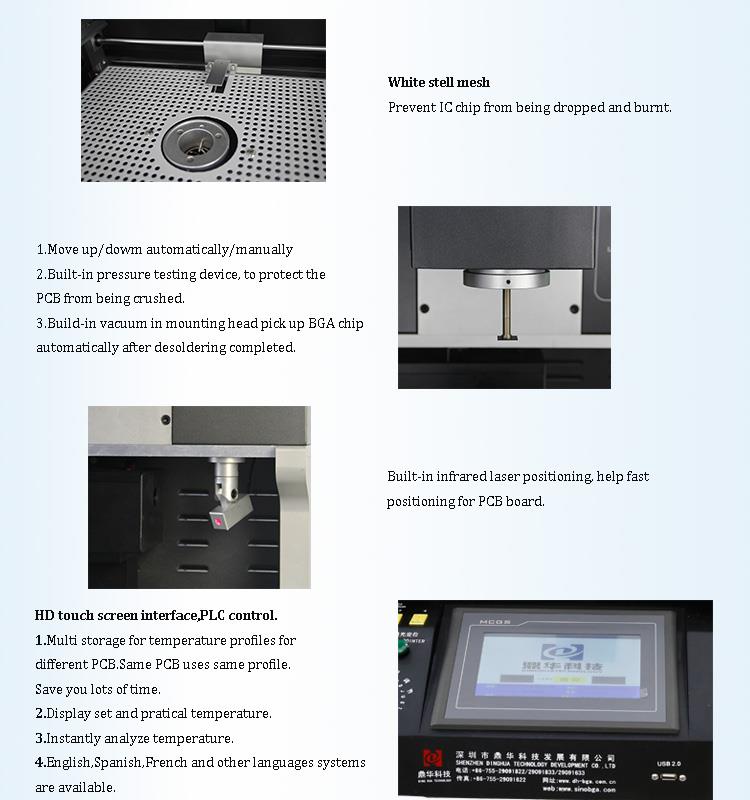

4.Structures ntawm Infrared CCD Lub Koob Yees Duab Tsis Siv Neeg Infrared BGA Rework chaw nres tsheb

5.Vim li cas cua kub reflow Tsis Siv Neeg Infrared BGA Rework chaw nres tsheb yog koj qhov kev xaiv zoo tshaj?

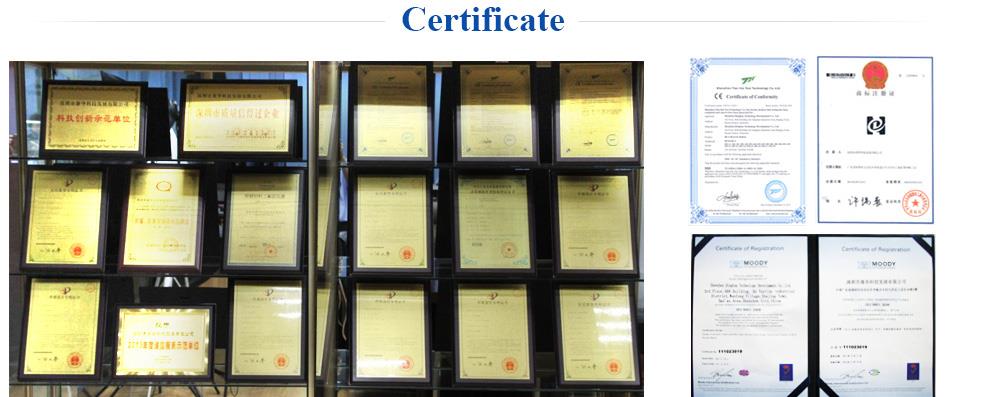

6.Certificate of Optical Alignment

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua kom zoo dua qhov system zoo,

Dinghua tau dhau ISO, GMP, FCCA, C-TPAT ntawm qhov chaw kuaj ntawv pov thawj.

7.Packing & shipping ntawm CCD lub koob yees duab

8.Shipment rauSplit Vision

DHL / TNT / FEDEX. Yog tias koj xav tau lwm lub sijhawm shipping, thov qhia rau peb. Peb yuav txhawb koj.

9. Muaj kev paub txog

HDI Lim Capacitor FANOUT Case rau Tsis Siv Neeg Infrared BGA Rework Chaw Nres Tsheb

Peb paub tias lim capacitors yog muab tso rau nruab nrab ntawm lub hwj chim mov thiab hauv av. Lawv ua haujlwm ob lub luag haujlwm tseem ceeb:

(1) Fais fab IC thaum lub sij hawm hloov ceev ceev, thiab

(2) Txo cov suab nrov ntawm lub zog hluav taws xob thiab hauv av.

Tag nrho cov lim capacitor xaiv cov tswv yim yog configured nrog laddered capacitance qhov tseem ceeb. Cov capacitors loj muab lub zog cia txaus, thaum cov capacitors me me muaj qhov inductance qis dua, tso cai rau lawv kom ua tau raws li IC tus nqi ceev thiab tso tawm cov kev cai rau Automatic Infrared BGA Rework Station.

Nyob rau hauv peb cov qauv tsim, thaum fanouting lub lim capacitor, ib tug me me, tuab hlau hlau yog rub los ntawm tus pin, ces txuas nrog lub hwj chim dav hlau los ntawm ib tug ntawm. Lub davhlau ya nyob twg hauv av tau ua haujlwm zoo ib yam. Lub hauv paus ntsiab lus ntawm fanout vias yog kom txo qis qhov chaw voj voog, uas ua rau txo qis tag nrho cov kab mob parasitic inductance.

Txoj kev fanout feem ntau rau lub lim capacitor yog qhia hauv daim duab hauv qab no. Lub lim capacitor yog muab tso rau ze rau lub hwj chim tus pin ntawm Tsis Siv Neeg Infrared BGA Rework Chaw nres tsheb.

Lub luag haujlwm ntawm lub lim capacitor yog muab txoj hauv kev uas tsis muaj impedance rau lub hwj chim mov network kom tsis txhob muaj suab nrov. Raws li pom nyob rau hauv daim duab hauv qab no (Lbellow sawv cev rau tus kheej-inductance thiab kev sib nrig sib inductance ntawm ob vias), thaum lub capacitor nyob ze rau IC, raws li qhia los ntawm cov kab dotted hauv daim duab, qhov sib nrig inductance ntawm Lbellow nce. Vim muaj kev sib koom ua ke ntawm kev sib nrig sib thiab nws tus kheej inductance, tag nrho inductance txo qis, ua rau kom ceev ceev thiab tawm ceev. Rau qhov Tsis Siv Neeg Infrared BGA Rework Chaw Nres Tsheb, Labove suav nrog qhov sib npaug series inductance (ESL) ntawm lub capacitor thiab mounting inductance.

Vim yog cov kab mob parasitic inductance ntawm lub lim capacitor, impedance ntawm lub capacitor ntawm lub siab zaus nce, tsis muaj zog lossis txawm tias tshem tawm nws lub suab nrov muaj peev xwm. Lub decoupling ntau ntawm ib tug raug nto-mount decoupling capacitor feem ntau yog nyob rau hauv 100 MHz.

Muaj ib hnub, peb pawg neeg lag luam tau hu rau kuv txog qhov teeb meem nrog tus neeg siv khoom tshiab HDI qhov project, nug seb peb puas tuaj yeem pab daws teeb meem. Raws li cov neeg siv khoom tawm tswv yim, schematics thiab layouts rau lawv cov SOC-hais lus modules tau tsim raws li lub demo board, tab sis ntau lub zog ua tsis tau raws li qhov kev cia siab thaum lub sij hawm kuaj cov khoom. Cov boards demo ua haujlwm zoo; lawv tau sab laj nrog lub chaw tsim khoom chip FAE, uas tau kuaj xyuas cov schematics thiab pom tsis muaj teeb meem. Txawm li cas los xij, lawv cov khoom siv 10- txheej, 3rd-order HDI tsim, thaum lub demo board siv ib qho kev txiav txim HDI tsim. FAE tau qhia lawv kom siv tag nrho lub rooj tsav xwm demo lossis simulate qhov hloov pauv. Cov neeg siv khoom xav tias vim lawv lub tuam txhab tsis paub zoo, tus thawj nti FAE tsis nquag pab lawv. Tib lub sijhawm, lawv cov PCBs tau tsim los ntawm "cov kws tshaj lij thiab paub txog" PCB engineers, uas pom tsis muaj qhov txawv txav thaum kuaj xyuas. Thaum kawg, lawv tuaj rau peb txhawm rau txheeb xyuas qhov teeb meem thiab saib seb peb tuaj yeem txhim kho qhov tsim kom tau raws li qhov yuav tsum tau ua ntawm Automatic Infrared BGA Rework Station.

Yam khoom:

- Cua kub reflow soldering tshuab

- Motherboard kho tshuab

- SMD micro Cheebtsam daws

- SMT rework soldering tshuab

- IC hloov tshuab

- BGA nti reballing tshuab

- BGA rov

- IC nti tshem tawm tshuab

- BGA rework tshuab

- Cua kub solder tshuab

- SMD rework chaw nres tsheb