CCD Lub Koob Yees Duab Optical Bga Reballing Tshuab

Optical CCD lub koob yees duab BGA reballing tshuab Tsis Siv Neeg BGA / SMT rework chaw nres tsheb, nrog rau qhov loj IR preheating cheeb tsam mus txog 430 * 480mm, xws li TV, cua txias thiab tub yees thiab lwm yam. . Cov khoom parameter ntawm optical CCD lub koob yees duab ...

Hauj lwm lawm

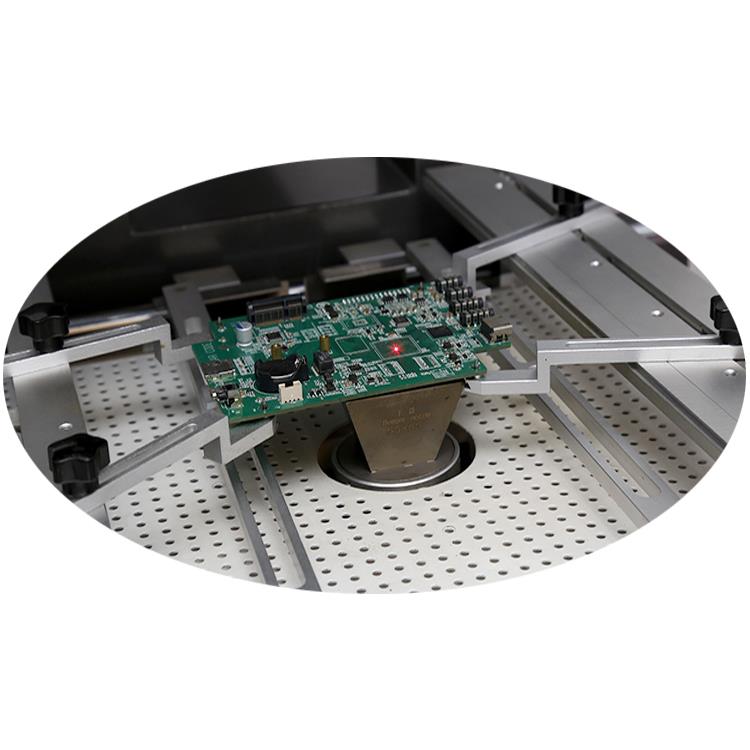

Optical CCD koob yees duab BGA reballing tshuab

Tsis siv neeg BGA / SMT rework chaw nres tsheb, nrog thaj tsam loj IR preheating mus txog 430 * 480mm, xws li TV,

cua txias thiab tub yees thiab lwm yam tuaj yeem kho tau, kuj, nws lub tshuab puv puv tsis siv neeg chip feeder yog qhov ntse heev.

Cov khoom parameter ntawm optical CCD koob yees duab BGA reballing tshuab

Tag Nrho Lub Zog | 6800W |

Lub tshuab cua sov sab saum toj | 1200W |

Hauv qab rhaub | 2nd 1200W, 3rd IR rhaub 4200W |

Hwj chim | AC220V ± 10 ~ 50Hz |

Hom kev ua haujlwm | Ob hom: phau ntawv thiab tsis siv neeg. HD kov npo, ntse txiv neej-tshuab, kev teeb tsa digital. |

Optical CCD lub koob yees duab lens | Pem hauv ntej / rov qab, sab xis / sab laug ntawm tes |

Lub koob yees duab magnification | 10x - 220x |

Workbench fine-tuning: | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

BGA positioning | Laser txoj hauj lwm, ceev thiab meej txoj hauj lwm ntawm pcb thiab bga |

PCB Positioning | Qhov chaw ntse, PCB tuaj yeem hloov kho hauv X, Y kev taw qhia nrog "5 ntsiab lus txhawb nqa" ntxiv rau V-groove PCB bracket ntxiv rau universal fixtures. |

Kev tswj qhov kub thiab txias | K sensor, kaw voj, PLC tswj |

Qhov tseeb qhov chaw: | ± 0.01 hli |

Temp raug | ± 1 degree |

Teeb pom kev zoo | Taiwan coj lub teeb ua haujlwm, txhua lub kaum sab xis adjustable |

Kub profile cia | 50000 pawg |

PCB loj | Max 530 × 490 mm Min 22 × 22 mm |

BGA chip | 2 x 2 - 80 x 80 mm |

Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

Sab nraud temper sensor | 4pc ua |

Tshuab Dimensions | 780 x 740 x 890 mm |

Net nyhav | 9 7 Kg |

Qhov hnyav tag nrho | 140 KG |

Packing Dimension | 118 * 86} * 121 cm |

Cov khoom lag luam ntawm optical CCD lub koob yees duab BGA reballing tshuab

Saib xyuas lub vijtsam, 15 nti, 1080P rau tag nrho cov dots ntawm nti thiab motherboard duab ntawm nws.

Muaj 2 qhov chaw cua sov nyob hauv qab lub motherboard, ib qho yog IR, ib qho yog cua kub, lub nozzle siv rau cua kub,

nws qhov loj tuaj yeem hloov pauv thiab kho tau.

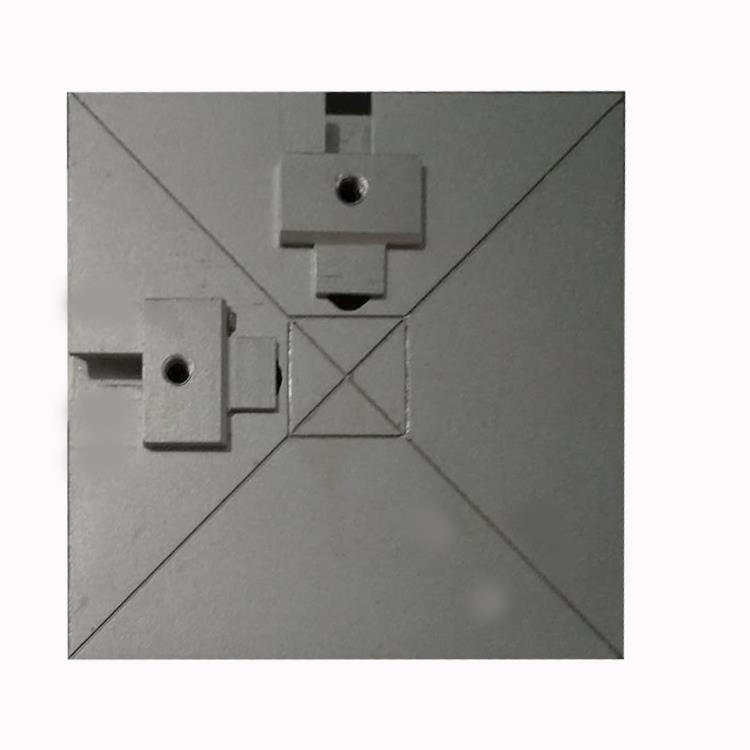

IR keyboards, 4 daim, thaum kho ib tug me me los yog heev me me motherboard, 2 ntawm lawv los yog tag nrho cov ntawm lawv yuav muab tua rau

tsis tsim nyog siv zog.

Chip feeder rau qhov loj me los ntawm 2 * 2 ~ 80 * 80mm, thiab nws yog tag nrho tsis siv neeg rau nti loaded los yog khaws los ntawm.

Hais txog peb lub rooj cob qhia thiab chaw ua haujlwm:

Dav thiab ci rhiav rau BGA rework tshuab raug, ntsib ISO9001: 2000 tus qauv, peb

Lub hom phiaj yog los muab cov khoom lag luam zoo rau txhua tus neeg siv khoom.

Ib qho ntawm peb cov chaw ua haujlwm rau kev muag khoom thiab kev tswj xyuas zoo, tag nrho peb cov kev muag khoom tau ncav cuag cov kev paub dhau los

BGA rework chaw nres tsheb, feem ntau, yog tias muaj teeb meem txog tshuab, feem ntau ntawm lawv tuaj yeem daws tau los ntawm peb tus kws tshaj lij muag khoom zoo.

Kev xa khoom, kev xa khoom thiab kev pabcuam ntawm BGA rework chaw nres tsheb:

Ua ntej xa khoom, lub tshuab yuav vibrating kuaj tsawg kawg yog 72 teev, peb yog thawj lub Hoobkas uas muab cov txheej txheem.

Cov khoom siv plywood ruaj khov nrog 5 txheej (fumigated), ua npuas ncauj hauv nruab nrab ntawm BGA rework chaw nres tsheb thiab lub thawv,

nrog qhov sib txawv ntawm lub thawv thiab hauv av kom yooj yim forked thiab nqa hauv tsheb lossis hauv av.

FAQ ntawm optical CCD koob yees duab BGA reballing tshuab

1. Q: Puas yuav cia lub tshuab ua haujlwm dua rau kev sim tom qab vibrating?

A: Tau kawg, lub tshuab yuav khiav tsawg kawg 12 teev, yog tias muaj teeb meem, nws yuav rov vibrating dua,

ces khiav dua, tsuas yog rau BGA rework chaw nres tsheb yog zoo meej thaum cov neeg tau txais.

2. Q: Koj puas tuaj yeem qhia kuv siv yog tias kuv yog tus tshiab?

A: Tseeb, feem ntau ntawm cov neeg muas zaub uas yuav cov BGA rework chaw nres tsheb nrog kho qhov muag alignment system yog tshiab,

thiab cov tshuab no yooj yim dua li phau ntawv qhia.

3. Q: Yog tias koj muaj lwm lub tshuab, tsuas yog BGA rework chaw nres tsheb?

A: Yog, peb muaj, xws li, Tsis siv neeg ntsia hlau xauv tshuab, Tsis siv neeg Soldering chaw nres tsheb thiab kua nplaum dispensing

tshuab thiab lwm yam.

4. Q: Koj puas tsim cov PCBs, chips lossis lwm yam khoom siv?

A: Tsis yog, peb tsom mus rau cov khoom siv automation, peb lub hom phiaj yog ua 21stxyoo pua ntau efficiency.

Qee qhov kev paub txog kev kho PCB:

Circuit Court txiav, Surface Circuits

Txoj kev no yog siv los txiav ib lub voj voog lossis luv luv. Ib feem me me ntawm lub voj voog raug tshem tawm ua kom tawg.

Qhov dav ntawm qhov so yuav tsum yog tsawg kawg yog qhov dav raws li qhov tsawg kawg nkaus tus neeg xyuas pib sib nrug. Riam phais

los yog kev kub ceev, Micro-Drill System yog siv. Txoj kev no yog pom zoo rau saum npoo Circuit Court txiav xwb.

Tom qab txiav, thaj chaw raug kaw nrog epoxy.

txheej txheem

Txheeb xyuas qhov Circuit Court lossis luv luv kom txiav. Txiav txim siab los ntawm cov duab kos duab lossis kos duab qhov twg qhov chaw zoo tshaj plaws

yog ua kom tawg. Qhov dav ntawm qhov so yuav tsum tsawg kawg yog qhov tsawg kawg nkaus uas yuav tsum tau muaj hluav taws xob sib nrug.

2. Ntxuav thaj chaw.

3. Ua tib zoo ua ob ntu me me nrog rab riam thiab tshem tawm qhov luv luv ntawm Circuit Court.

4. Xaiv lub pob zeb uas tsim nyog thiab muab tso rau hauv Micro-Drill System. Teeb qhov ceev kom siab.

Lub pob zeb yuav tsum yog kwv yees li qhov dav tib yam li lub voj voog yuav raug txiav

5. Ua tib zoo ua 1 lossis 2 txiav raws li xav tau.

6. Tshawb xyuas txuas ntxiv kom paub tseeb tias lub voj voog raug txiav.

7. Ntxuav thaj chaw.

8. Sib tov epoxy. Yog xav tau, ntxiv xim tus neeg sawv cev rau cov epoxy sib xyaw kom haum

9. PC board xim.

10. Kev kho kom tiav.