Cov Huab Cua Kub Optical BGA Reballing Station

Kev kub ntawm qhov muag BGA reballing chaw nres tsheb Lub tshuab DH-G730 yog qhov chaw nres tsheb hauv IC ICI, nrog 15 nti npo npo, thiab 1080P, thiab import optical CCD koob yees duab uas tau faib ob xim rau nti thiab PCB, tshwj xeeb tshaj yog siv IC ntawm lub xov tooj txawb, xws li, iphone, Samsung, Huawei thiab Xiaomi ...

Hauj lwm lawm

Kub cua kho qhov muag BGA reballing chaw nres tsheb

Lub cav no DH-G730 yog qhov chaw nres tsheb hauv IC ICI, nrog 15 nti npo npo, thiab 1080P, thiab import optical CCD koob yees duab uas tau faib ob xim rau CHIP thiab PCB, tshwj xeeb tshaj yog siv IC ntawm cov xov tooj txawb, xws li, iphone, Samsung , Huawei thiab Xiaomi etc.

Cov khoom txhawb ntawm cov cua kub kho qhov muag BGA reballing chaw nres tsheb

Tag Nrho Fais Fab | 2500W |

Sab saum toj rhaub | 1200W |

Qab rhaub | 1200W |

Lub zog | AC110 ~ 240V ± 10% 50 / 60Hz |

Kev ua haujlwm hom | Ob hom: kev ceev thiab tsis siv neeg. HD kov npo, ntse txiv neej, tshuab qhov chaw. |

Optical CCD koob yees duab lens | 90 ° qhib / folding |

Saib kev tshuaj ntsuam | 1080P |

Lub koob yees duab magnification | 1x - 200x |

Workbench nplua-tuning: | ± 15mm forward / backward, ± 15mm txoj cai / sab laug, |

Upper micrometer rau kev kho lub kaum ntse ntse | 60 ͦ |

Kev sau npe tseeb: | ± 0.01 hli |

PCB txoj hauj lwm | Kev txawj ntse ntse, PCB tuaj yeem kho hauv X, Y kev taw qhia nrog "5 ntsiab lus txhawb" + V-groov pcb bracket + universal fixtures. |

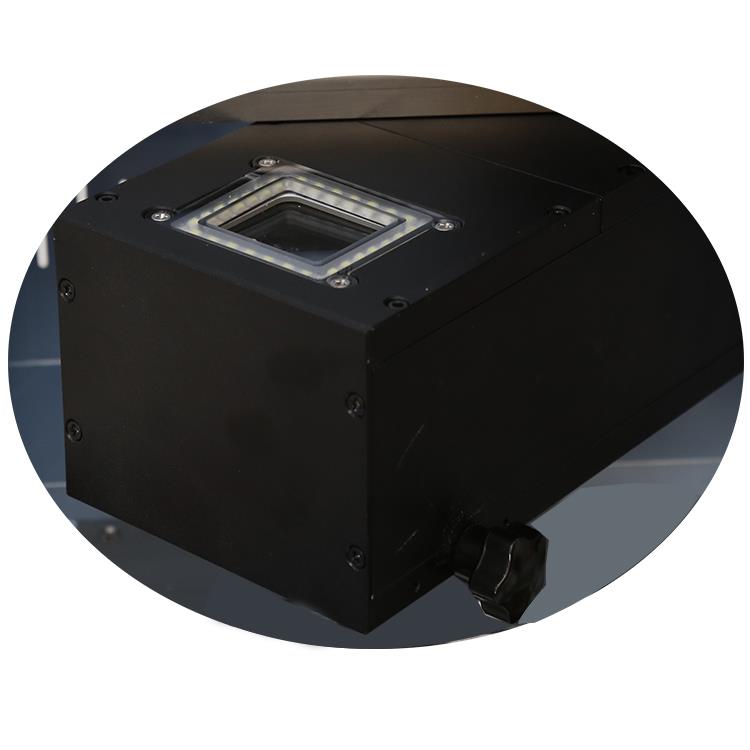

Teeb pom kev zoo | Taiwan coj lub teeb ci, txhua lub teeb tsa tau |

Kub profile cia | 50000 pawg |

Kub tswj | K sensor, kaw voj |

Khiav txujci | PLC tswj |

Temp tseeb | ± 1 ℃ |

PCB me me | Txhua yam xov tooj txawb xov tooj |

BGA nti | 1x1 - 80 x 80 hli |

Yam tsawg nti ntxig | 0.15 hli |

Sab nraub qis txias | 1pc |

Qhov ntev | L420 × W450 × H680 hli |

Net nyhav | 35KG |

Khoom lus ntawm cua txias kho qhov muag bga reballing chaw nres tsheb

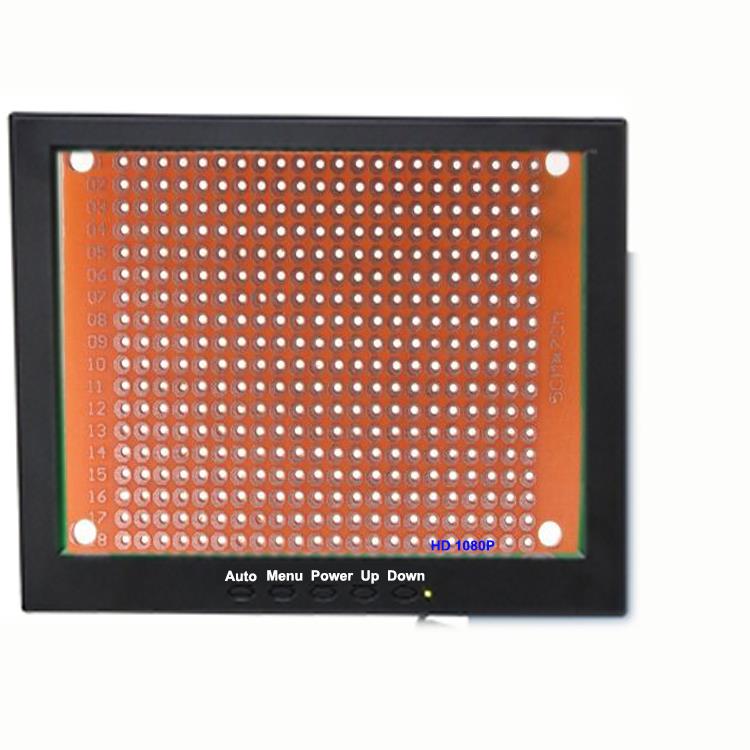

HD monitor screen, 1080P, dots ntawm nti thiab PCBA tuaj yeem tshwm sim rau nws, thaum tsom pom ob hom xim xim, cia li nias "pib" pib lub tshuab.

Imported optical CCD lub koob yees duab, uas tuaj yeem tau duab ob hom xim ntawm qhov kev tshuaj ntsuam xyuas, thiaj li ua kom zoo rau bga, IC thiab QFN thiab lwm yam.

Micrometer rau PCB zoo-tune rau sab xis thiab sab laug thiab nram qab lossis rov qab thaum nws mus nti rau PCB.

Bga rework chaw nres tsheb cov nyees khawm haum, xws li, cov cua ntim kho rau huab cua kub sab thaum thau los yog lub khwb nyom, khawm ceev thiab teeb lub teeb rau CCD lub koob yees duab.

DH-G730 bga rework chaw nres tsheb khiav lag luam interface, yooj yooj yim thiab yooj yim rau kev khiav lag luam, tag nrho cov parameter yuav tau teem rau ntawm lub vijtsam kov, nws yog qhov chaw tswj cov tshuab no tag nrho.

Txog peb lub koom haum

Peb lub Hoobkas sab nraum

Kev loj hlob thiab kev tshawb fawb rau cov tshiab style Bga rework chaw nres tsheb tsim

Qhov chaw kaj thiab dav qhib rau BGA rework chaw nres tsheb uas qhia rau cov neeg tuaj xyuas

Ib ntawm peb chaw ua haujlwm

Peb qhov kev cob qhia rau BFA qhov chaw ua hauj lwm kev teeb tsa kev sib koom ua ke

Kev xa, shipping thiab pabcuam ntawm cua txias kho qhov muag bga reballing chaw nres tsheb

Tag nrho cov tshuab yuav ntim rau hauv rooj plaub ntawm plywood (tsis tas yuav tsum tau fumigation), thiab muab ntoo tuav, ua npuas ncauj thiab me me thawv ntawv thiab lwm yam, rau cov tshuab ruaj.

Txhua lub cav yuav muaj tsawg kawg yog ib xyoo rau lub tshuab tag nrho, thiab 3 xyoos rau cua sov, yog tias kev txiav txim siab tshaj 10 teev ntawm tib lub sijhawm, lub xyoo warranty yuav yog 3 xyoos.

FAQ ntawm lub cua txias kho qhov muag bga reballing chaw nres tsheb

1. Q: Yog tias kuv yuav tsum tau siv lub tshuab raj rau kub cua?

A: Tau, yog tias koj tus ntiv tes tsis muaj xwm txheej, lub tshuab no yuav ua li cas.

2. Q: Thaum kuv ntxuav qhov seem, kuv puas yuav tsum haus cawv?

A: Tsis tau, koj kuj tuaj yeem siv tau hnyav, rau yav tom ntej, tom qab siv qhov ntawd, koj yuav tsum ntxuav koj tes.

3. Q: Pes tsawg lub koob tshuaj lub tshuab kom sov?

A: 2 heaters, ob leeg yog cua kub, raws li tag nrho cov xov tooj ntawm tes PCBs me heev, lawv tsis tas yuav tsum tau preheated.

4. Q: Nws loj npaum li cas nws tuaj tos tau los ntawm nws lub plhaub ntsiag to?

A: Tus neeg muaj pes tsawg yog los ntawm 1 * 1 ~ 80 * 80mm

Kho cov kev paub lossis cov tswv yim

Qhov Kho, Txoj Kev Hloov

TXHEEM

Hom no yog siv los kho qhov kev puas tsuaj loj heev rau lub qhov los yog hloov qhov loj me, qhov chaw lossis qhov chaw ntawm lub cuab yeej los yog qhov teeb meem. Lub qhov taub yuav muaj cov khoom ua rau, xov hlau, txuas rau, pins, qeeb lossis lwm yam khoom siv los ntawm nws. Txoj kev kho no siv txoj hlua ntawm kev sib txuas ntawm lub rooj tsav khoom thiab lub zog siab epoxy kom ruaj khov rau hauv lub qhov chaw. Tom qab cov khoom siv tshiab tau ua ke nyob rau hauv qhov chaw tshiab qhov yuav ua rau drilled. Txoj kev no siv tau rau ib tog ib sab, ob npaug los yog multilayer PC boards thiab sibtham.

CEEV FAJ

Cov kev sib raug zoo hauv cov txheej txheem yuav tsum tau ntom xaim ntxiv.

TXOJ CAI

1.0 Nthuav Lus

2.1 Kev Sib Koom Tes Hauv Tsev

2.2 Tu

2.5 Noj thiab Ua Ntej

2.7 Epoxy Mixing thiab Ua Haujlwm

CUAB YEEJ & COV NTAUB NTAWV

Base Material Qws

Nqus tsev vacuum

Kawg Mills

Epoxy

Micro-Drill System

Tsom

Sib Ntseg

Cub

Precision Riam

Precision Laum System

Razor Pom

Kaw, Kub Kub

Cov ntaub so

TXHEEJ TXHEEM

1.Clean the area.

2. Tshem tawm qhov puas qhov tsis zoo lossis qhov tsis zoo uas siv cov cav ntoo los yog kev ua tiav. Zeb lub qhov uas siv qhov kev txiav txim siab tho xovxwm los yog tshuab milling rau qhov tseeb. Txoj kab uas hla ntawm lub cuab tam yuav tsum yog tsawg tshaj li qhov ua tau tseem tsis tau tag nrho lub cheeb tsam.

CEEB TOOM

Cov haujlwm ua haujlwm yuav ua kom muaj nuj nqi electrostatic.

3. Siv ib qho khoom los hloov cov khoom nqus. Base khoom pas nrig yog tsim los ntawm FR-4 taub hau phom. Txiav qhov ntev txog 12.0 hli (0.50 ") ntev tshaj li qhov xav tau.

4. Caw qhov chaw ua haujlwm tshiab.

5. Siv cov ntaub nplaum kub los tiv thaiv qhov chaw ntawm lub PC Board bordering cheeb tsam rework.

6.Hauv lub epoxy.

7.Ua ob lub taub hau thiab lub qhov nrog epoxy thiab haum ua ke. Thov cov ntawv ntxiv ntawm epoxy puag ncig ntawm cov khoom tshiab. Tshem tawm epoxy ntau heev.

8.Cov epoxy ib qhov txheej txheem 2.7 Epoxy Mixing thiab Handling.

CEEV FAJ

Qee yam khoom yuav ua rau muaj kev sov siab.

9. Tshem daim ntaub xev thiab txiav tawm cov khoom uas siv ntau tshaj plaws uas siv rab phom pom. Zeb lossis ua kom lub taub hau yaug nrog lub rooj tsavxwm.

10. Ua tiav cov txheej txheem ntawm kev muab redrilling qhov thiab ntxiv circuitry raws li yuav tsum tau ua.