Nto Mount IC Hloov Tshuab

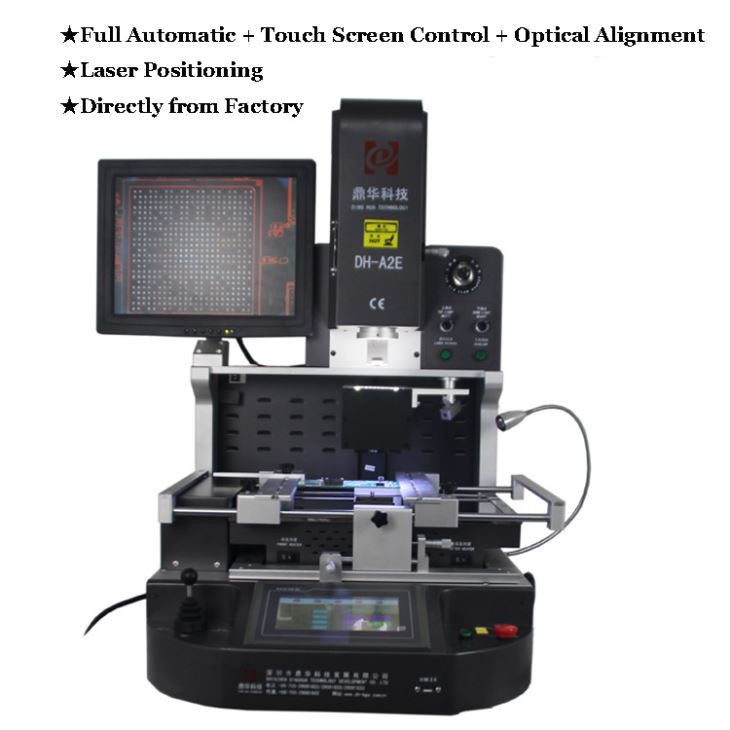

Nto Mount IC Hloov Tshuab BGA QFN LED SMT SMD Cheebtsam rework chaw nres tsheb. Lub tshuab no muaj qib siab heev ntawm automation.

Hauj lwm lawm

Tsis Siv Neeg Surface Mount IC Hloov Tshuab

Qauv: DH-A2E

1.Khoom nta ntawm Tsis Siv Neeg Infrared Surface Mount IC Hloov Tshuab

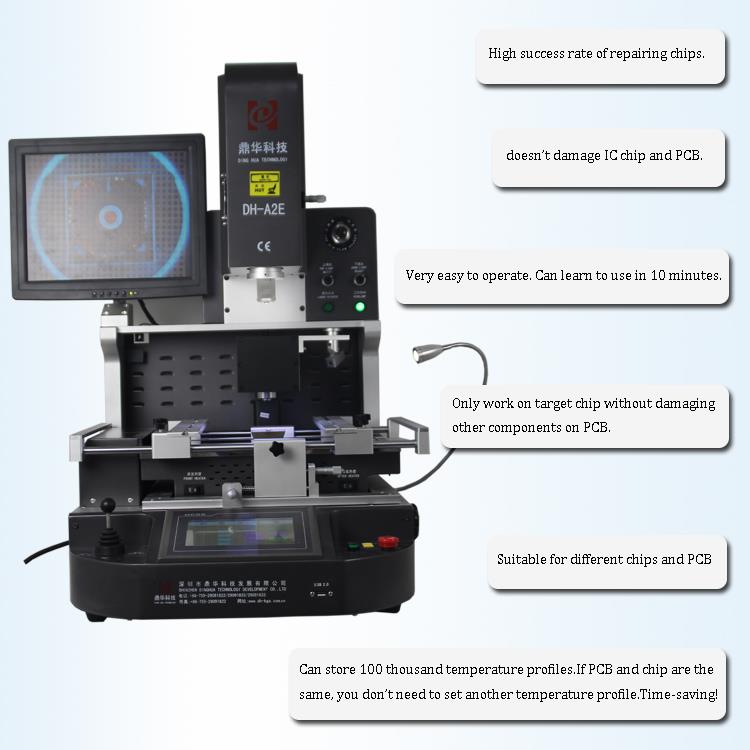

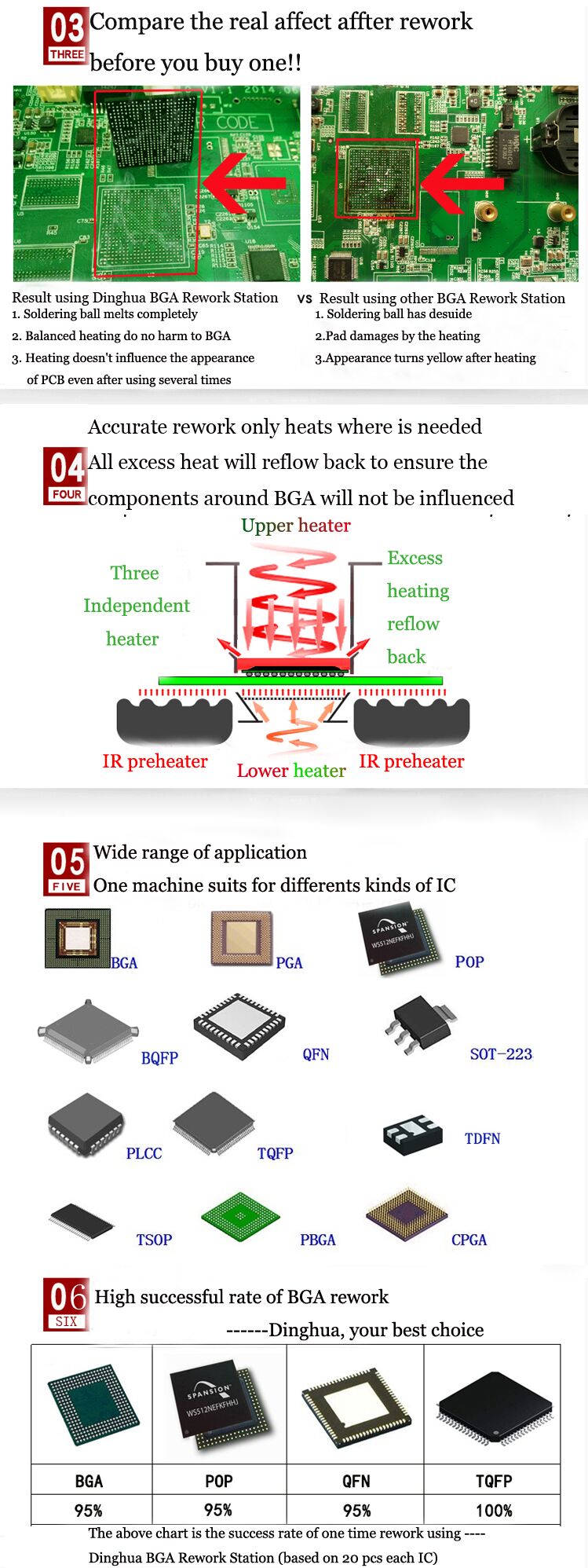

• Kev ua tiav siab ntawm kev kho chip-theem. Desoldering, mounting thiab soldering txheej txheem yog tsis siv neeg.

• Kev sib haum xeeb yooj yim.

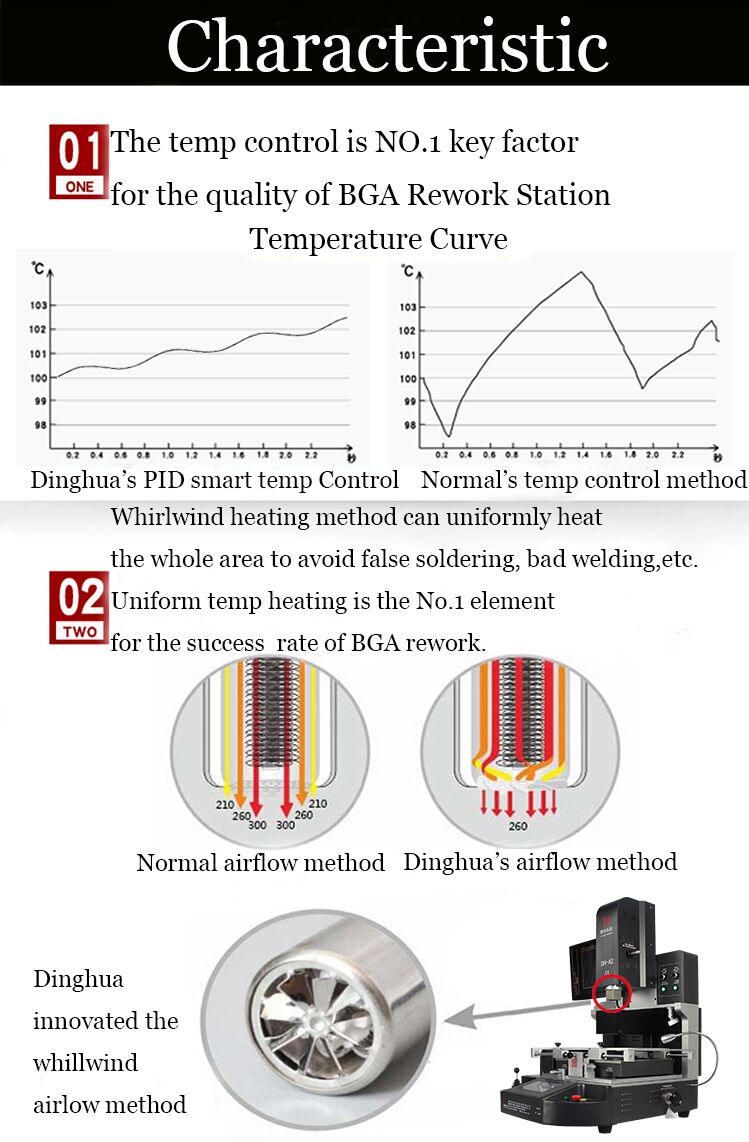

• Peb tus kheej kub cua sov + PID tus kheej qhov chaw hloov kho, qhov tseeb kub yuav nyob ntawm ± 1 degree

• Ua hauv lub tshuab nqus tsev twj, khaws thiab tso BGA chips.

• Tsis siv neeg txias ua haujlwm.

2.Specification ntawm huab cua kub Automated nto Mount IC hloov tshuab

| Hwj chim | 5300w |

| Lub tshuab cua sov sab saum toj | Cua kub 1200w |

| Hauv qab rhaub | Cua kub 1200W. Infrared 2700w |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | Ktype thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGA chip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

3.Cov ntsiab lus ntawm Cov Cua Kub Tsis Siv Neeg Nto Mount IC Hloov Tshuab

4.Vim li cas thiaj xaiv Peb Lub Tshuab Nto Mount IC Hloov?

5.Certificate of Optical alignment automatic Surface Mount IC Hloov Tshuab

6.Packing npentawm Optics align CCD Lub Koob Yees Duab Nto Mount IC Hloov Tshuab

7. Kev xa khoom ntawm Tsis Siv Neeg Nto Mount IC Hloov Tshuab Split Vision

Peb xa lub tshuab ntawm DHL / TNT / UPS / FEDEX, uas yog ceev thiab nyab xeeb. Yog tias koj xav tau lwm cov nqe lus ntawm kev xa khoom, thov koj xav tiv tauj peb.

8. Hu rau peb tam sim teb thiab tus nqi zoo tshaj.

Email: john@dh-kc.com

MOB/WhatsApp/Wechat: +8615768114827

Nyem qhov txuas ntxiv kuv WhatsApp:

https://api.whatsapp.com/send?phone=8615768114827

9.Related paub txog Automatic Surface Mount IC Hloov Tshuab

Case: PCBA Daim Ntawv Thov rau Epson APS hauv Kev Npaj Ua Ntej

I. Kev taw qhia txog qhov project

1. Cov xwm txheej tam sim no ntawm Kev Npaj Ntau Lawm

Cov txheej txheem tsim khoom ntawm PCBA (Printed Circuit Board Assembly) ntawm Lub Tuam Txhab A (tom qab no hu ua "Lub Tuam Txhab A") ua raws li cov qauv ntau ntau, me me, thiab cov qauv tsim tawm siab. Lub tuam txhab tsim ntau tshaj 1,000 hom khoom, nrog ntau tshaj 200 cov khoom tseem ceeb. Nws tuav ntau pua qhov kev txiav txim ntau lawm txhua lub hlis, uas decompose rau ntau txhiab tus neeg ua haujlwm xaj hla ntau cov txheej txheem.

Lub tuam txhab A txoj kev npaj ua raws li peb theem qauv, suav nrog lub tuam tsev npaj, chav tswj kev tsim khoom, thiab kev teem caij ua haujlwm. Kev npaj, teem caij, txiav txim tso tawm, tshaj tawm, thiab kev hloov kho feem ntau vam khom rau cov txheej txheem ntawm phau ntawv, suav nrog cov rooj sib tham thiab cov txheej txheem ntawv. Teem sijhawm lub rooj sib tham muaj ob zaug hauv ib lub lis piam, nrog ob txoj kev npaj rau txhua hnub. Lub sijhawm teem sijhawm ua haujlwm yog hnyav heev thiab nyuaj, xav tau cov neeg ua haujlwm txawj ntse nrog kev paub dhau los.

Thaum lub tuam tsev tswj xyuas cov khoom tsim tawm cov lus txiav txim ntau lawm rau txhua lub rooj cob qhia, tus neeg ua haujlwm xa tawm cov phiaj xwm tsim cov sijhawm ntxaws raws li qhov kev npaj ua tiav thawj zaug, cov peev txheej muaj, thiab cov sijhawm sib koom ua haujlwm. Raws li cov phiaj xwm rau txhua lub rooj cob qhia muaj kev sib txuas, cov kws npaj kev cob qhia sib txuas lus raws li qhov tsim nyog los kho thiab tswj cov sijhawm.

2. Kev Sib Tw Ua Lag Luam

Cov txheej txheem ntau lawm hauv PCBA kev lag luam yog raws li hauv qab no: "SMT (Surface Mount Technology) - yoj soldering - kuaj - laus." Raws li kev tshawb fawb xav tau, APS (Advanced Planning Scheduling) tus qauv txheej txheem tau txiav txim siab yog: "SMT - yoj soldering - kuaj - kev laus." Cov teeb meem kev teem caij tseem ceeb yog raws li nram no:

(1) SMT txheej txheem

SMT, los yog Surface Mount Technology, yog ib qho kev sib txuas ntawm cov txheej txheem uas tsis muaj cov hlau lead lossis luv-lead nto-mount Cheebtsam txuas rau saum npoo ntawm lub rooj tsavxwm luam tawm (PCB) lossis lwm yam substrate thiab soldered siv cov txheej txheem reflow lossis dip soldering.

SMT Rhiav muaj ntau cov kab ntau lawm, txhua tus muaj peev xwm ua tau ntau hom khoom siv. Cov hauv qab no yuav tsum tau txiav txim siab thaum npaj kev tsim khoom:

- Kab Load Balancing: Kev siv zog yuav tsum tau ua kom sib npaug ntawm cov khoom thauj ntawm cov kab, kom ntseeg tau tias lub sijhawm ua tiav zaum kawg rau txhua kab yog sib npaug li sai tau.

- Kev Tsim Nyog: Lub hom phiaj yog los xyuas kom meej tias cov kab ntau lawm ua haujlwm tsis tu ncua, nrog rau lub sijhawm tsis ua haujlwm tsawg, kom siv cov khoom siv ntau tshaj plaws.

- Sub-resource Restrictions (Stencil Limitations): Txhua yam khoom xav tau cov peev txheej stencil tshwj xeeb. Txhua stencil tsuas yog siv los ntawm ib kab ntau lawm ib zaug. Kev txiav txim siv tib stencil tsis tuaj yeem ua tiav ib txhij.

- Txo Pwm Hloov Sijhawm: Yog tias ntau qhov kev txiav txim yuav tsum tau ua tib yam stencil, yuav tsum tau siv zog los npaj lawv rau kev tsim khoom txuas ntxiv kom txo tau lub sijhawm siv hloov stencils.

- Order Lead Time: Teem sijhawm yuav tsum tau teem caij raws li qhov kev txiav txim xa tuaj kom ntseeg tau raws sijhawm.

- SMT Kab Variability: Qee cov kab ntau lawm sai dua lwm tus. Kev txiav txim uas tuaj yeem ua tiav ntawm cov kab nrawm dua yuav tsum tau ua ntej rau cov kab ntawd.

- Tsis Siv Neeg Teem caij: Thaum cov kev cai teem caij teem tseg, kev npaj tuaj yeem hloov kho nrog ib zaug nias siv cov kev txawj ntse, tsis siv neeg teem caij los kho cov lus teb.

- Kuaj ntau lawm txawv txav: Cov khoom siv poob qis, kev saib xyuas, khoom siv tsis txaus, lossis kev txiav txim thaum muaj xwm txheej ceev tuaj yeem cuam tshuam kev tsim khoom. Nyob rau hauv tas li ntawd, qhov kev txiav txim ntau lawm yuav tsum nyob twj ywm unchanged yog hais tias yav tas los xauv, thiab ib tug ceev teb txoj kev npaj yuav tsum tau muab coj los siv.

- Rolling Teem caij: Cov phiaj xwm yuav tsum tau hloov kho raws li kev tsim khoom, dov lub sijhawm kom haum raws li qhov tsim nyog.

- Kev npaj khoom siv: Lub sijhawm pib raug rau txhua qhov kev txiav txim tuaj yeem txiav txim siab, tso cai rau lub tuam txhab logistics npaj thiab faib cov ntaub ntawv raws li. Qhov no yuav pab txo qis qis thiab txo qis hauv cov txheej txheem lossis kab-sab cov khoom muag.

Yam khoom:

- Cua kub reflow soldering tshuab

- Motherboard kho tshuab

- SMD microcomponents daws

- LED SMT rework soldering tshuab

- IC hloov tshuab

- BGA nti reballing tshuab

- BGA rov

- Soldering / desolding khoom

- IC nti tshem tawm tshuab

- BGA rework tshuab

- Cua kub soldering tshuab

- SMD rework chaw nres tsheb

- IC tshem tawm cov cuab yeej