BGA Rework Reballing Chaw nres tsheb

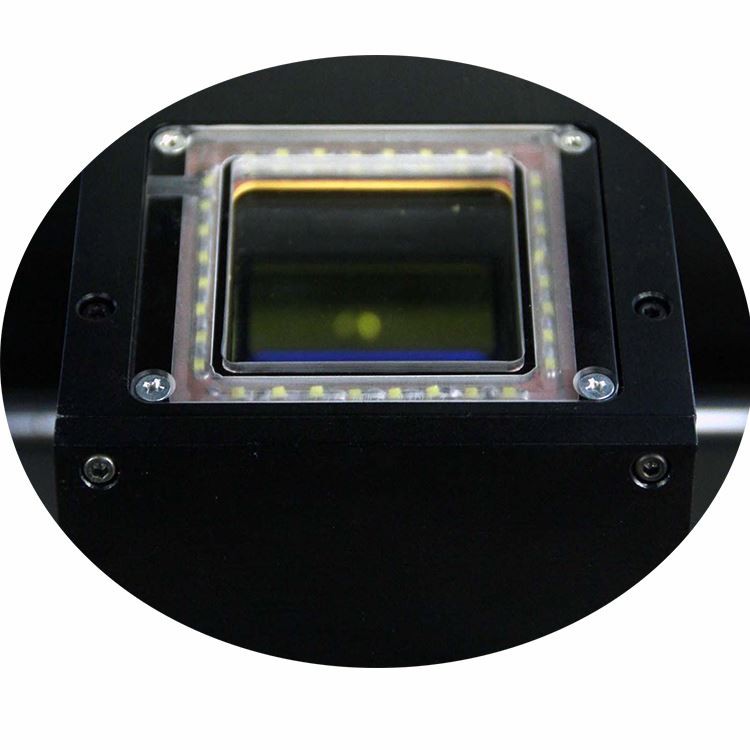

1. Optical CCD alignment system thiab saib xyuas kev tshuaj ntsuam rau imaging.2. Kev sib cais tsis pom kev rau cov dots ntawm cov nti thiab PCB.3. Real-time kub profiles generated.4. 8 ntu ntawm qhov kub thiab txias / sijhawm / tus nqi tuaj yeem muaj

Hauj lwm lawm

BGA rework reballing chaw nres tsheb

DH-A2 yog tus qauv kub muag tshaj plaws hauv kev lag luam txawv teb chaws thiab Suav lag luam, kom deb li deb tau thov los ntawm Foxconn,

Huawei thiab ntau lub Hoobkas, kuj yog ib qho nrov rau lub khw kho, xws li, Apple chaw pabcuam,

Xiaomi chaw pabcuam thiab lwm lub khw kho tus kheej, thiab lwm yam. vim nws yog high efficiency thiab nqi-zoo.

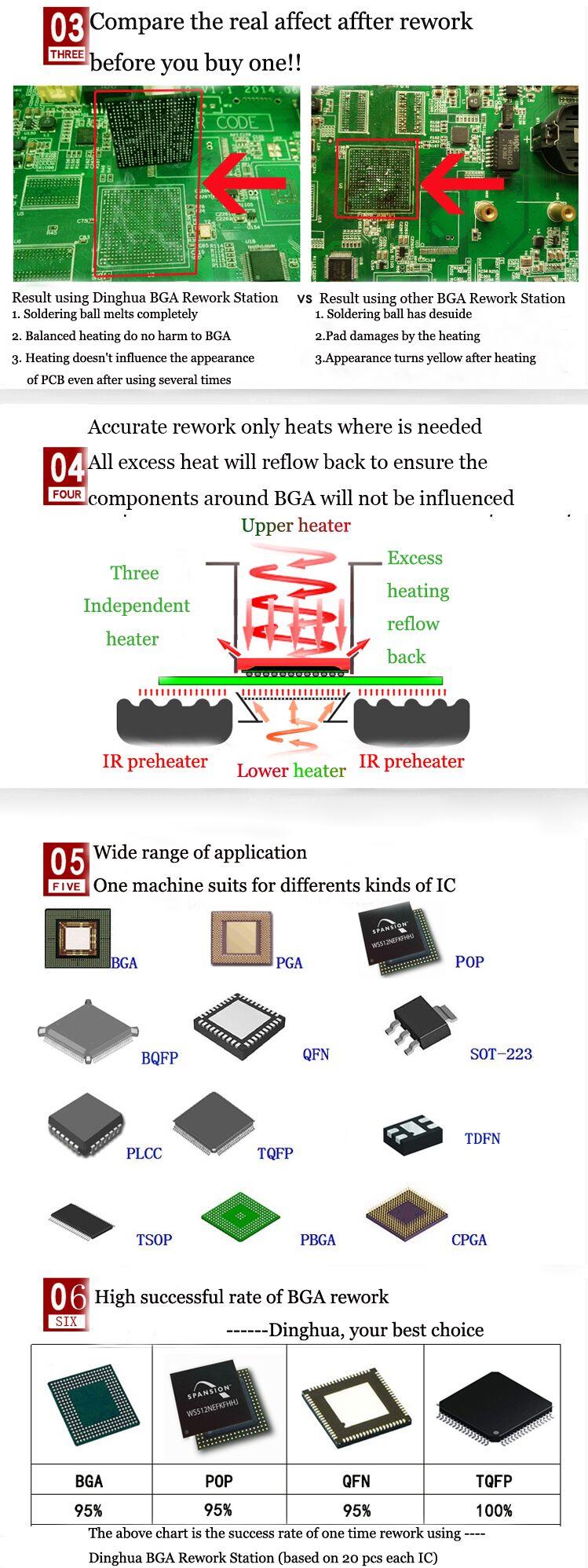

1. Daim ntawv thov ntawm BGA rework reballing chaw nres tsheb

Rau solder, reball, desolder ntau hom chips:

BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED chips, thiab lwm yam.

2. Khoom nta ntawm BGA rework reballing chaw nres tsheb

* ruaj khov thiab ntev lifespan (tsim rau 15 xyoo siv)

* tuaj yeem kho cov motherboard sib txawv nrog tus nqi ua tau zoo

* nruj me ntsis tswj cua sov thiab txias kub

* Optical alignment system: mounting kom raug hauv 0.01mm

* Yooj yim rau kev khiav lag luam. Leej twg tuaj yeem kawm siv nws hauv 30 feeb. Tsis xav tau kev txawj tshwj xeeb.

3. Specification ntawmBGA rework reballing chaw nres tsheb

| Fais fab mov | 110 ~ 240V 50/60Hz |

| Tus nqi zog | 5400W |

| Auto qib | solder, desolder, khaws thiab hloov, thiab lwm yam. |

| Optical CCD | tsis siv neeg nrog lub chip feeder |

| Khiav tswj | PLC (Mitsubishi) |

| nti sib nrug | 0.15 hli |

| Touchscreen | nkhaus tshwm, lub sij hawm thiab qhov kub thiab txias |

| PCBA loj muaj | 22 * 22 ~ 400 * 420mm |

| chip loj | 1 * 1 ~ 80 * 80mm |

| Qhov hnyav | ib 74kg |

| Packing dims | 82 * 77 * 97cm |

4. Cov ntsiab lus ntawmBGA rework reballing chaw nres tsheb

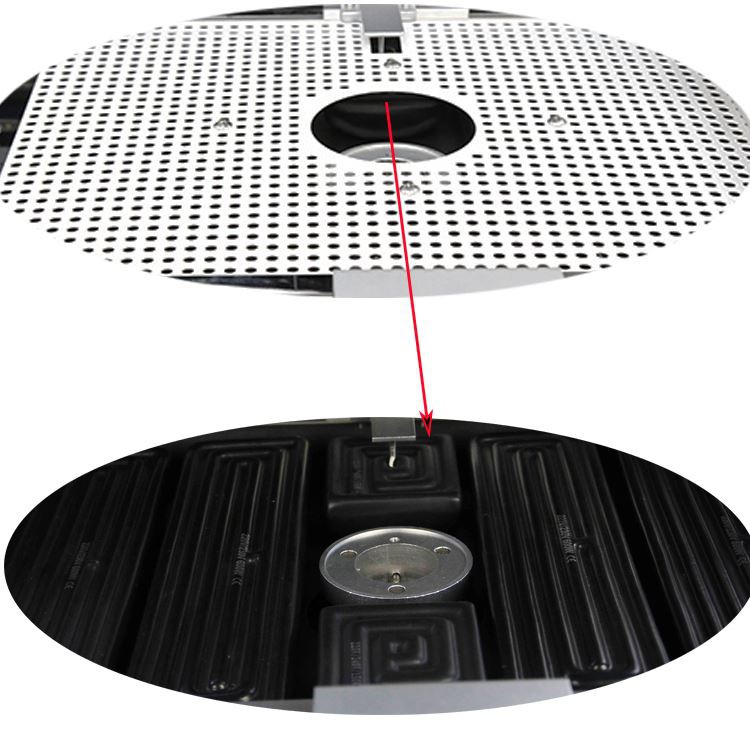

1. Sab saum toj kub-cua thiab lub tshuab nqus tsev nqus tau teeb tsa ua ke, uas yooj yim khaws cov nti / cov khoom siv rauua ke.

2. Optical CCD nrog lub zeem muag sib cais rau cov dots ntawm lub nti vs motherboard duab ntawm lub vijtsam saib.

3. Lub vijtsam zaub rau lub nti (BGA, IC, POP thiab SMT, thiab lwm yam) vs nws cov motherboard sib phim cov dots dlhosua ntej soldering.

4. 3 thaj chaw cua sov, huab cua sab saud, cua kub qis thiab IR preheating zones, uas tuaj yeem siv rau me me.

iPhone motherboard, kuj, mus txog lub computer ann TV mainboards, thiab lwm yam.

5. IR preheating cheeb tsam them los ntawm steel-mesh, uas ua rau cov cua sov cov ntsiab lus sib npaug thiab nyab xeeb.

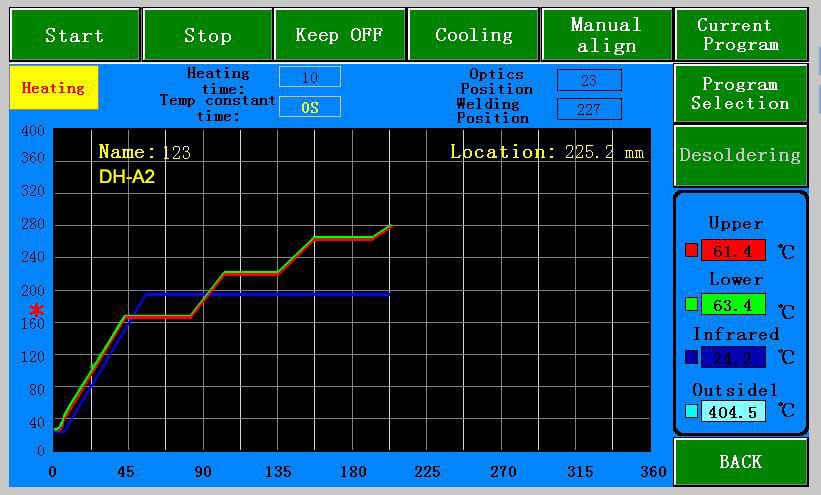

6. Kev ua haujlwm interface rau lub sijhawm thiab qhov kub thiab txias, qhov kub thiab txias profiles tuaj yeem khaws cia li

ntau li 50,000 pawg.

5. Vim li cas thiaj xaiv Peb BGA rework reballing chaw nres tsheb?

6. Daim ntawv pov thawj ntawm BGA rework reballing chaw nres tsheb

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua kom zoo dua qhov system zoo,

Dinghua tau dhau ISO, GMP, FCCA, C-TPAT ntawm qhov chaw kuaj ntawv pov thawj.

7. Ntim & Xa khoom ntawm BGA rework reballing chaw nres tsheb

8. Kev xa khoom rau BGA rework reballing chaw nres tsheb

DHL, TNT, FEDEX, SF, Kev thauj mus los hauv hiav txwv thiab lwm cov kab tshwj xeeb, thiab lwm yam .. Yog tias koj xav tau lwm lub sijhawm xa khoom,

thov qhia rau peb.Peb yuav txhawb koj.

9. Cov nqe lus them nqi

Hloov chaw hauv txhab nyiaj, Western Union, Credit Card.

Thov qhia rau peb yog tias koj xav tau lwm yam kev txhawb nqa.

10. Kev qhia ua haujlwm rau BGA rework chaw nres tsheb DH-A2

11. Cov kev paub zoo rau BGA rework reballing chaw nres tsheb

Cov kauj ruam siv BGA rework chaw nres tsheb

1. Pib tus txheej txheem:

1.1 Txheeb xyuas tias kev sib txuas ntawm cov khoom siv hluav taws xob sab nraud yog 220V.

1.2 Qhib lub hwj chim hloov ntawm txhua chav tsev ntawm lub tshuab

3. Cov txheej txheem disassembly:

3.1 Daim npav PCBA BGA yuav raug muab tshem tawm yog tsau rau hauv kev txhawb nqa ntawm daim npav PCBA.

3.2 Txav mus rau PCBA mus rau qhov siab txwv bar, kho qhov siab ntawm kev txhawb nqa ncej kom sab saum toj ntawm PCBA nyob rau hauv kev sib cuag.

nrog rau hauv qab ntawm qhov siab txwv bar.

3.3 Tig lub taub hau ntawm lub moos mus rau 90 degree txoj hauj lwm ncaj qha rau pem hauv ntej thiab txav PCBA mus rau nruab nrab ntawm txoj hauj lwm ntawm lub com-

ponent yuav tsum tau muab tshem tawm thiab qhov chaw liab ntawm lub taub hau kev sib raug zoo.

3.4 Siv tus kov los xaiv qhov kev pab cuam cua sov kom tshem tawm cov khoom

3.5 Tso lub taub hau rau sab laug cua sov ncaj qha rau ntawm cov khoom kom raug tshem tawm thiab lub tshuab yuav cia li ua kom sov cov khoom.

3.6 Yog rhuab mus rau 190 degrees, lub tshuab emits ib intermittent "beep ... beep" suab. Lub sijhawm no, qhov kub thiab txias yog calibrated o-

nce (control button); Thaum lub tshuab ua kom sov kom emit ib "beep ... nruam beep", lub tshuab nqus tsev hloov yog nyob rau, nias kom nqa lub taub hau,

nqus cov tivthaiv, tig lub taub hau cua sov ntawm sab laug platform ntawm cov khoom tivthaiv, nias kom tsa koj lub taub hau, BGA yuav

poob cia li thiab BGA yuav raug tshem tawm.

3.7 Ua raws li cov kauj ruam saum toj no kom tshem tawm cov khoom.

4. Cov txheej txheem ntawm kev thauj khoom cov khoom:

4.1 Lub PCBA tau thauj khoom raws li cov kauj ruam tau piav qhia hauv cov ntsiab lus 3.1-3.2 saum toj no.

4.2 Teem lub BGA yuav tsum tau soldered nyob rau hauv nruab nrab ntawm lub platform uas lub BGA txuas nrog, txav lub PCB bracket (sab laug-txoj cai dire-

ction) kom BGA ncaj qha nyob rau hauv lub tshuab nqus tsev nozzle. Nias lub khawm, qhov qis ntawm lub teeb lub taub hau mus rau hauv qab kawg,

manually tig qhov hloov ntawm lub taub hau teeb kom paub tseeb tias lub nozzle nce mus txog saum npoo ntawm BGA thiab ua rau lub cuab yeej a-

utomatically tig ntawm lub tshuab nqus tsev hloov (lub tshuab nqus tsev vacuum), ces manually tig nws mus rau qhov qub, nias lub khawm kov thiab

lub taub hau positioning cia li nce mus rau qhov chaw siab tshaj.

4.3 Tshem tawm cov cuab yeej kaw kom nws ncaj qha nyob rau hauv lub nozzle tivthaiv, txav lub PCB board tuav kom txoj hauj lwm ntawm

cov tivthaiv yuav tsum tau soldered yog ncaj qha nyob rau hauv cov ntaubntawv povthawj siv cuab yeej thiab kho qhov siab ntawm cov khoom tsim nyog los tsim

daim duab meej

4.4 Koj tuaj yeem pom tias lub monitor muaj liab BGA pins thiab xiav PAD ncoo cov ntsiab lus. Kho ob txoj hlua khi rau lawv qhov sib xws

ua haujlwm ib zaug. Tom qab muab tso rau hauv nruab nrab, thawb lub locator mus rau qhov chaw qub thiab nias lub khawm kov kom tawm ntawm BGA co-

mponent mounts nyob rau hauv txoj hauj lwm ntawm cov khoom sib txuas ntawm PCB board kom txog thaum lub tshuab nqus tsev hloov lub teeb (lub tshuab nqus tsev vacuum)

tawm mus, nqa me ntsis lub taub hau mounting thiab nias lub pob kom rov qab mus rau lub taub hau mounting.

4.5 Rov ua dua cov kauj ruam 3.3-3.5 saum toj no

4.6 Yog tias cua sov rau 190 degrees, lub tshuab emits ib "beep ... beep". Saib cov txheej txheem soldering nyob rau hauv qab ntawm cov khoom

los ntawm kev saib), qhia tias cov khoom siv tau ua tiav ib txwm, tshem lub taub hau cua sov thiab txav lub PCBA mus rau

kiv cua kom txias.

5. Kev ntsuas kub:

Stripping kub qhov chaw:

Saib cov configuration muab nrog lub tshuab

Welding kub hloov:

Saib cov configuration muab nrog lub tshuab

6. Cov teeb meem xav tau kev saib xyuas:

1. Ua tib zoo saib xyuas kev sib cuag ntawm txhua lub cuab yeej siv thaum lub sijhawm ua haujlwm kom tsis txhob muaj kev puas tsuaj rau cov khoom muaj feem xyuam.

2. Tus neeg teb xov tooj saib xyuas nws tus kheej kev nyab xeeb kom tsis txhob muaj hluav taws xob poob siab thiab kub hnyiab.

3. Khaws thiab tswj cov khoom siv, ua kom txhua yam huv si thiab huv si.

4. Tom qab siv cov khoom siv, nws yuav tsum tau teeb tsa raws sijhawm, ua kom zoo thiab ua raws li 5S cov cai.

5. Yog tias muaj teeb meem tshwm sim, daws tam sim ntawd los ntawm tus kws tshaj lij lossis cov txheej txheem engineer.