TXAWB IC Reballing Tshuab

Daim ntawv thov ntawm DH-A2 tsis siv neeg BGA rwork chaw nres tsheb / iPhone / ipized kho / khoos phis tawj / MacBook / PC kho; 3. Xbox 360 / ps2 / ps3 / ps4 Wii thiab yog li ntawm kev ua yeeb yaj kiab kev ua si; 4.Thoe LED / SMD /MO / IC BGA reworks; 5. BGA VGA CPA CPU GPU SOLDERING DESTONDERING; 6.Bga Daim Chips, QFP QFN Chip, PC, Plcc PSP PSYE dua kev ua haujlwm.

Hauj lwm lawm

Txawb IC Reballing Tshuab rau iPhone, Huawei, Samsung, LG, thiab lwm yam.

Qhov dav dav siv ntawm niaj hnub txawb cov khoom siv tau yooj yim heev kom yooj yim thiab kev lom zem rau cov neeg siv. Txawm li cas los xij, nws tseem tau tsa lub bar rau cov kws kho mob tu cov tub txawg.

Txhawm rau kom tau pab cov khoom siv no, peb tau qhia lub xov tooj ntawm tes hnyav lub cav thawj zaug, ua kom cov kev pab kho zoo. Cov cuab yeej no yog tsiag ntawv los ntawm nws txoj kev ua tau zoo thiab nrawm, tso cai rau kev kho mob ceev thiab ua tau zoo.

Rau ntau hom ntawm cov khoom siv txawb, xws li iPhone, Huawei, Samsung, LG, thiab lwm yam. Nws yog sib xws nrog cov txheej txheem ntawm cov ntim ntim ntim sib txawv, thiab muaj peev xwm puv thiab muaj qhov chaw puas tsuaj, tsis tas yuav muaj kev tshem tawm. Lub tshuab cia li kho qhov ntsuas kub thiab lub sijhawm ua haujlwm raws li yuav tsum tau ua. Qhov no ua kom muaj kev nyab xeeb ua haujlwm thaum txhim kho cov nyiaj tau muag thiab cov neeg siv khoom txaus siab.

Lub ic txawb pob zeb hnyav pob tshuab kuj muab kev pabcuam tom qab muag.

Demo video ntawm DH-A2E Tsis Siv Neeg Kho Kev Kho Tsis Siv Neeg Chaw Nres Tsheb:

1. Cov khoom nta

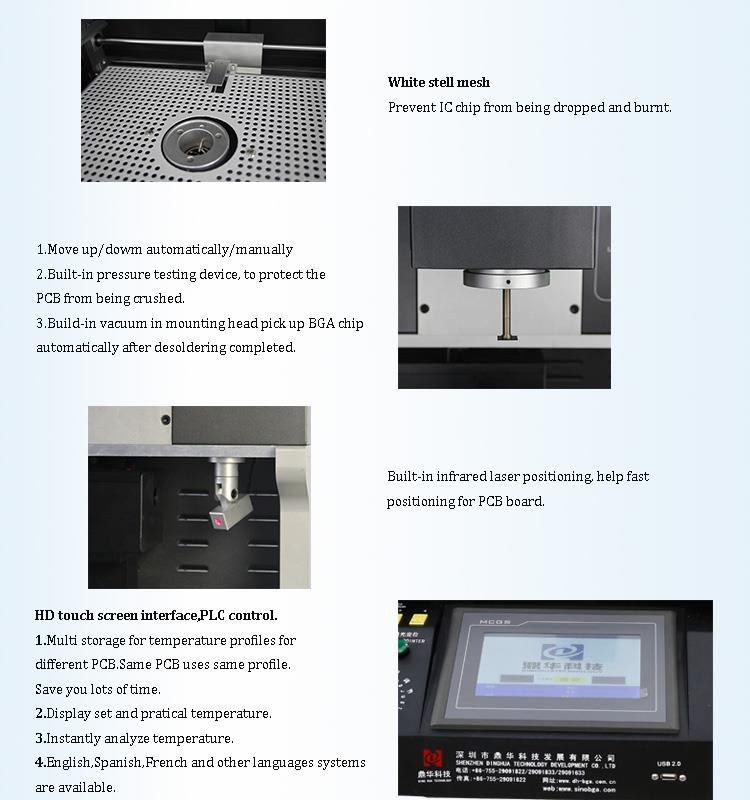

• Desoldering, mounting thiab soldering cia.

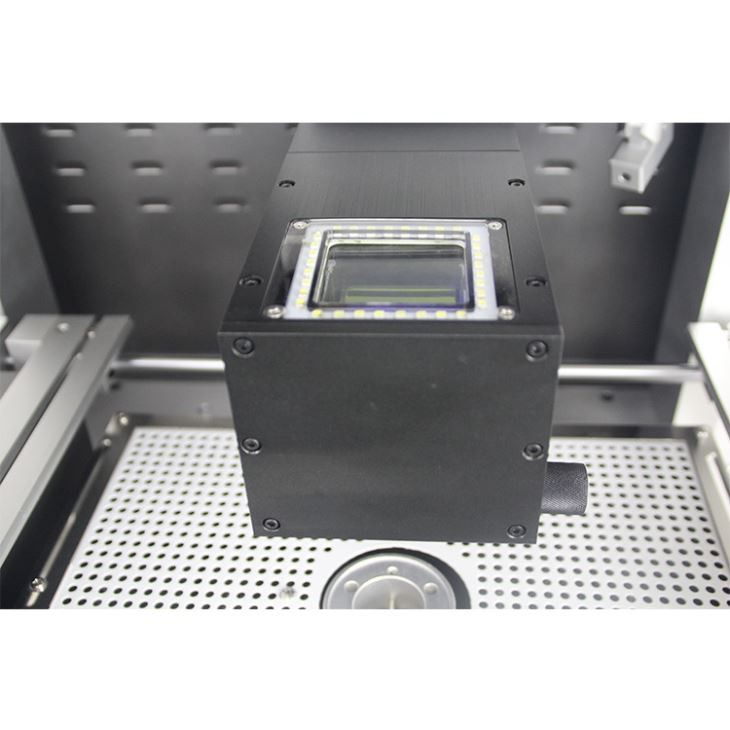

• Lub Koob Yees Duab CCD kom meej meej ntawm txhua qhov soldering sib koom tes,

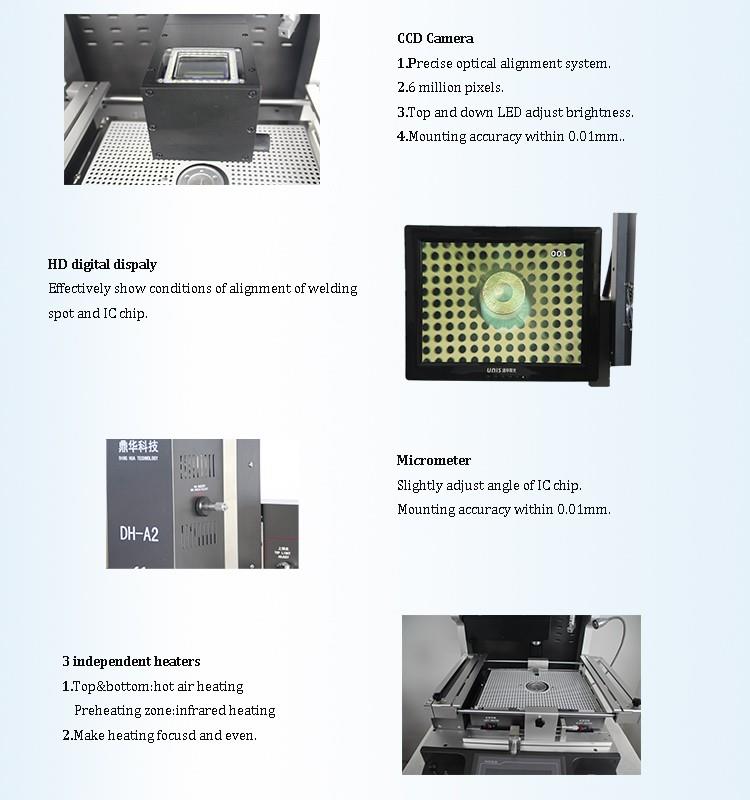

• Peb qhov chaw ywj pheej aforones kom ua kom pom qhov kub thiab txias.

• Cov cua kub kub ntau qhov chaw nruab nrab txhawb yog qhov tshwj xeeb tshaj yog siv rau cov PCB loj loj thiab BGA

nyob rau hauv qhov chaw ntawm PCB. Zam kev mob khaub thuas thiab cov teeb meem IC-poob.

• Qhov ntsuas kub ntawm qhov kub ntawm cov cua sov kub tuaj yeem ncav cuag kom muaj ntau li 300 degree, tseem ceeb rau

Loj Motherboard. Meanwhile, lub pas dej sab saud tuaj yeem tsim raws li synchronized los yog

kev ua haujlwm zoo.

DH-G620 yog lig zoo ib yam li DH-A2, tuaj tos, nrog kev sib tw, tsis muaj teeb meem dab tsi rau kev sib tw thiab tsis muaj, koj tuaj yeem ua tus tswv nws hauv ib teev.

2.Specification

| Hwjchim | 5300W |

| Sab saum cua | Huab Cua Kub 1200W |

| BLOM RHAUB | Huab Cua Kub 1200W, infrared 2700w |

| Kev pab fais fab | AC220V ± 10% 50 / 60HZ |

| Qho loj dav | L530 * W670 * H790 hli |

| Possilioning | V-Groove PCB txhawb nqa, thiab nrog rau universal fixture |

| Tswj Qhov Kub | K Hom thermocouple. Kaw Voop tswj. Indegentent Cua Kub |

| Temperature Qhov tseeb | ± 2 Qib |

| PCB Loj | Max 450 * 490 hli, Min 22 * 22 hli |

| Workbench nplua-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15 xyoo / sab laug |

| Bgachip | 80 * {80-1} * 1 hli |

| Yam tsawg kawg nti nti | 0. 15 hli |

| TEMP Sensor | 1 (awalal) |

| Qhov hnyav | 70Kg |

3.details ntawm mobile IC reballing tshuab

4.Why xaiv peb lub xov tooj ntawm tes rov qab?

5.Certificate

Kom muab cov khoom lag luam zoo, Shenzhen Dinghua thev naus laus zis thev naus laus zis Co., Ltd yog

Thawj zaug kom dhau UL, E-cim, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab zoo tag nrho

Lub kaw lus zoo, Dinghua tau dhau ISO, GMP, FCCA, C-TPAT hauv audit ntawv pov thawj.

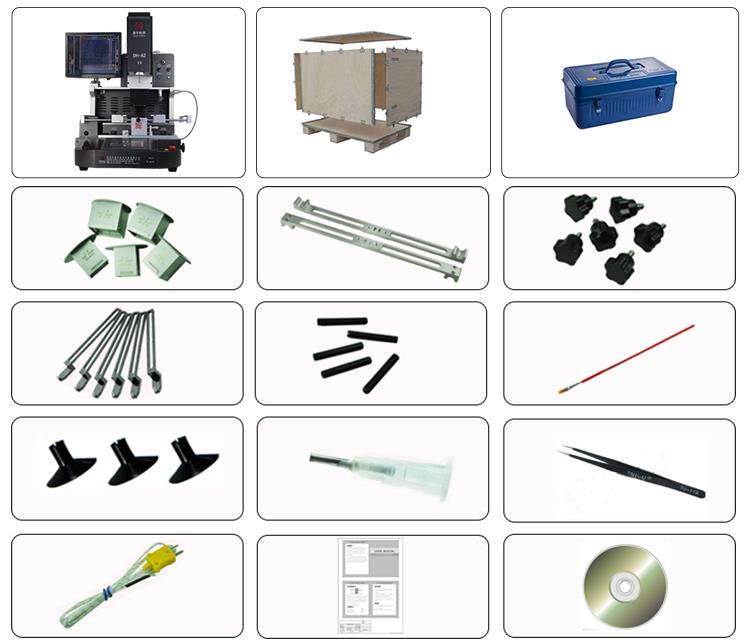

6.Packing & Zaub mov xa tuaj ntawm lub tshuab nyiaj rov qab los ntawm tes

7.Cov rau txawb Ic Reballing Tshuab

Email: john@dh-kc.com

WhatsApp / WeChat / Mob: {+86 157 6811 4827

8.related kev paub

BGA Kev Txij Nkawm Kev Txawj Ntse

(1). BGA npaj ua ntej desoldering.

Teem cov xwm txheej ntsuas ntawm Sunkko 852B kom sov 280 Qib ~ 310 degree; DesTloDING LUB SIJ HAWM: 15 vib nas this;

airflow tsis: × × × (1 ~ 9 cov ntaub ntawv tuaj yeem yog preset los ntawm cov neeg siv code);

Thaum kawg, tus desolder yog teem rau hauv hom hom tsis siv neeg, thiab Sunkko 202 BGA anti-static tin-plating

kho chaw nres tsheb yog siv rau mount lub xov tooj ntawm tes PCB board nrog lub taub hau thoob ntiaj teb thiab kho nws ntawm lub ntsiab-

Talance platform.

(2). Desoldering

Nyob rau hauv BGA Board kho thev naus laus zis, nco ntsoov cov kev taw qhia thiab muab tso rau ntawm lub nti ua ntej unsoldering.

Yog tias tsis muaj cov ntawv luam tawm ntawm tus PCB, khij nws ib ncig nrog tus cim, txhaj ib qho me me ntawm flux

Hauv qab ntawm BGA, thiab xaiv ib qho tsim nyog BGA. Qhov loj me ntawm BGA tshwj xeeb VUAM NOZZLE yog mounted

ntawm 852b.

Dlhos tus tuav ntsug nrog BGA, tab sis nco ntsoov tias lub nozzle yuav tsum yog 4 hli deb ntawm qhov sib faib-

ent. Nias lub khawm pib ntawm 852b kov. Tus desolder yuav cia li untwist nrog lub preset parame-

ters.

Tom qab cov desolddering, BGA tivthaiv tau muab tshem tawm nrog lub nqus phaj tom qab 2 vib nas this, yog li ntawd tus thawj

Toold pob tuaj yeem faib covyees faib ntawm cov ntaub ntawv ntawm PCB thiab BGA, uas yog qhov zoo dua rau kev kawm-

sib npaug bga soldering. Yog tias muaj qhov seem ntawm tin rau PCB ncoo, siv anti-static soldering chaw nres tsheb los lis

Nws tusyees. Yog tias nws tau txuas nrog, koj tuaj yeem thov flux dua ntawm PCB, thiab tom qab ntawd pib 852b kom sov

Tus PCB ntxiv, thiab thaum kawg ua cov tin pob zoo thiab du. Lub Tin ntawm BGA yog tshem tawm kiag li

Los ntawm kev tawm ntawm rab riam los ntawm cov antistatic soldering chaw nres tsheb. Them sai sai rau anti-zoo li qub thiab tsis dhau-temba-

ture, txwv tsis pub, nws yuav ua rau lub ncoo lossis txawm tias lub motherboard.

(3). Kev ntxuav ntawm BGA thiab PCB.

Ntxuav cov PCB ncoo nrog cov dej siab nrawm-huv-huv, siv tshuab nqus tsev ultrasonic (nrog cov cuab yeej siv hluav taws xob) los sau cov

Ntxuav dej, thiab ntxuav lub nraub qaum.

(4). BGA Nti Cog Tin.

BGA Chip Tinning yuav tsum siv laser-punched steel ntawv nrog ib-tog raj ntawm ib-tog raj mesh. Lub thickness ntawm

Daim ntawv hlau yuav tsum muaj 2 hli tuab, thiab tag nrho cov phab ntsa yuav tsum tau ua kom du thiab huv si. Qis dua

ib feem ntawm lub raj raj (hu rau lub ntsej muag ntawm BGA) yuav tsum muab piv. Sab saum toj (scraping mus rau hauv lub qhov me me) yog

10. "15μm. (Cov ntsiab lus saum toj no tuaj yeem pom los ntawm kaum-fass magnifying iav), kom cov luam ntawv luam ntawv

Tau yooj yim poob rau hauv BGA.

(5). Vuam ntawm BGA chips.

Thov ib qho me me ntawm cov tuab rau cov bga sib dhos pob thiab pcb pads (siab huv siab yog yuav tsum muaj, ntxiv cov nquag rosin

Mus rau qhov kev tshuaj ntxuav tes ntshiab kom yaj), thiab khaws cov cim thawj los tso rau BGA. Nyob rau tib lub sijhawm ntawm w-

elding, BGA tuaj yeem sib raug zoo thiab muab tso rau kom tiv thaiv nws los ntawm kev tawg ntawm huab cua kub, tab sis kev saib xyuas yuav tsum yog

coj tsis txhob muab cov flux ntau dhau, txwv tsis pub, cov nti yuav raug hloov vim muaj npuas ntau dhau los tsim los ntawm

Rosin. Lub PCB PCB tseem muab tso rau hauv cov chaw nres tsheb txij nkawm zoo li qub thiab tsau nrog lub taub hau dav dav thiab muab tso rau

tav toj. Cov tsis muaj nqis ntawm cov ntse tau txais yog preset rau ib tug kub ntawm 260 degree c ~ 280 degree c, vuam

Lub sijhawm: 20 vib nas this, lub dav hlau tsis tau hloov pauv. Tsis siv neeg soldering khawm yog txhais thaum lub

BGA Nozzle yog mus raws li lub nti thiab nplooj 4 hli. Raws li BGA To Holder pob melts thiab pcb ncoo ua kom zoo dua

Tin alloy soldering, thiab cov npoo nro ntawm cov cam pob ua rau lub nti kom tau nruab txawm tias

Nws yog keeb kwm deviated los ntawm cov ntawv loj kom nws ua tiav. Nco ntsoov tias BGA tsis tuaj yeem siv thaum lub sijhawm

lding txheej txheem. Txawm hais tias cov cua hlob siab dhau lawm, lub sijhawm luv nqi hluav taws xob yuav tshwm sim ntawm cov phuam qhwv hauv qab BGA.