BGA Chip Reballing Thiab Rework

BGA Chip Reballing Thiab Rework DH-A2 nrog kev ua tiav zoo ntawm kev kho. Txais tos kom xaj.

Hauj lwm lawm

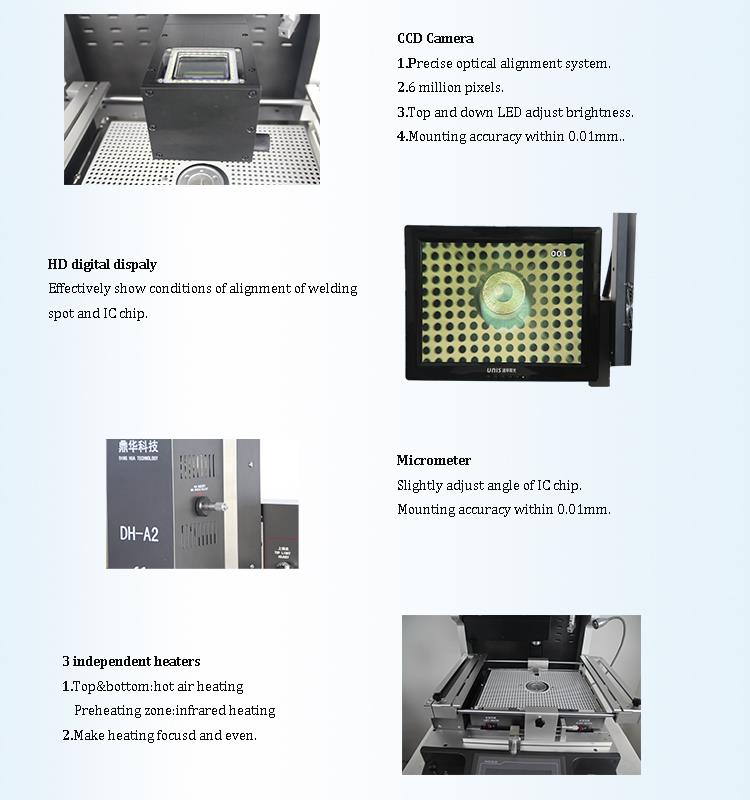

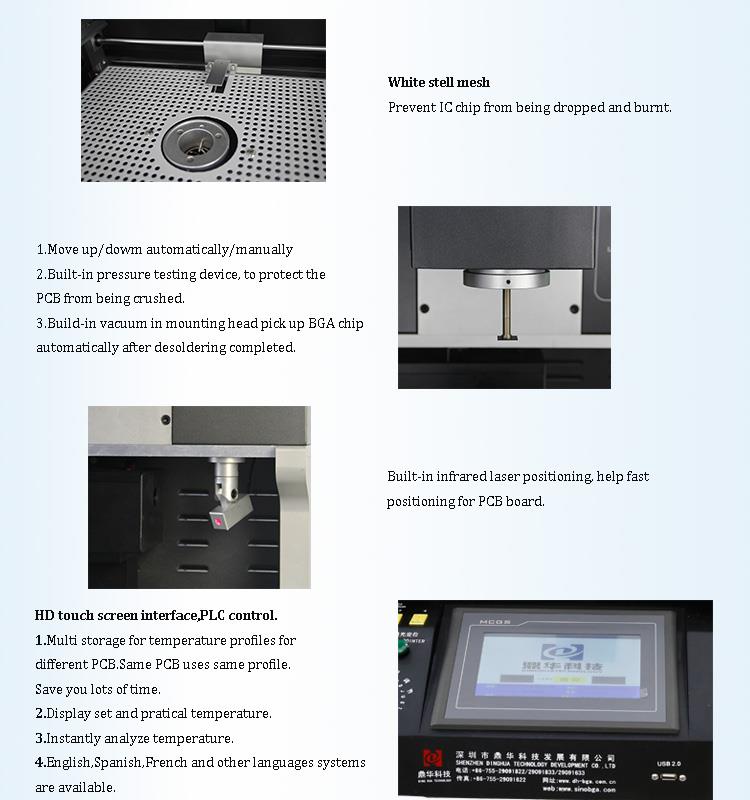

Tsis Siv Neeg BGA Chip Reballing Thiab Rework

Tsis Siv Neeg BGA Chip Reballing thiab Rework yog txheej txheem uas siv lub tshuab tshem tawm thiab hloov qhov yuam kev lossis puas

pob daim phiaj array (BGA) chips ntawm cov ntawv luam tawm Circuit Board (PCBs). Lub tshuab yog nruab nrog lub tshuab cua sov, lub tshuab soldering

cuab yeej, thiab lub tshuab nqus tsev uas siv los ua ke los tshem tawm thiab hloov cov chips.

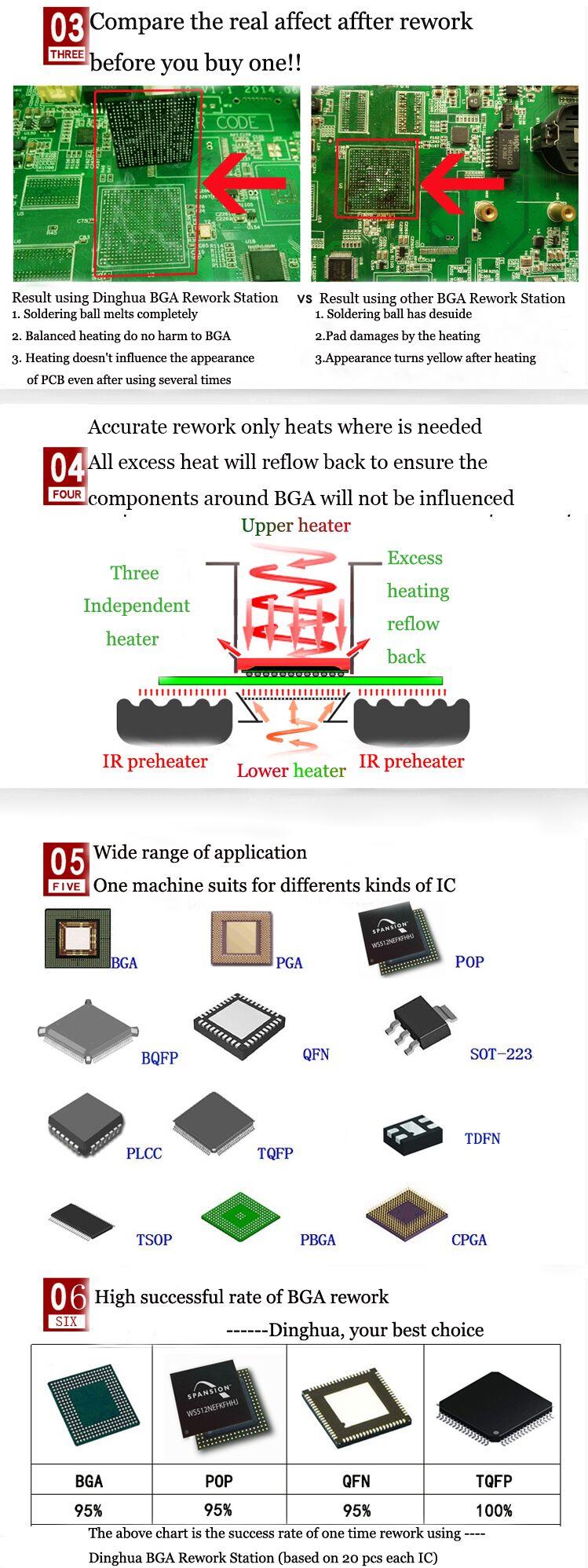

1.Application Of laser positioning BGA Chip Reballing Thiab Rework

Ua haujlwm nrog txhua hom motherboards lossis PCBA.

Solder, reball, desoldering ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP,

PBGA, CPGA, LED nti.

DH-G620 yog ib yam nkaus li DH-A2, cia li desoldering, tuaj tos, muab rov qab thiab soldering rau ib nti, nrog optical alignment rau mounting, txawm tias koj muaj kev paub los yog tsis, koj muaj peev xwm txawj nws nyob rau hauv ib teev.

2.Specification ntawm DH-A2BGA Chip Reballing Thiab Rework

| zog | 5300W |

| Lub tshuab cua sov sab saum toj | Cua kub 1200W |

| Hauv qab lub rhaub | Cua kub 1200W.Infrared 2700W |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | K hom thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGAchip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

3.Cov ntsiab lus ntawm Tsis Siv Neeg BGA Chip Reballing Thiab Rework

4.Vim li cas thiaj xaiv pebBGA Chip Reballing Thiab Rework Split Vision?

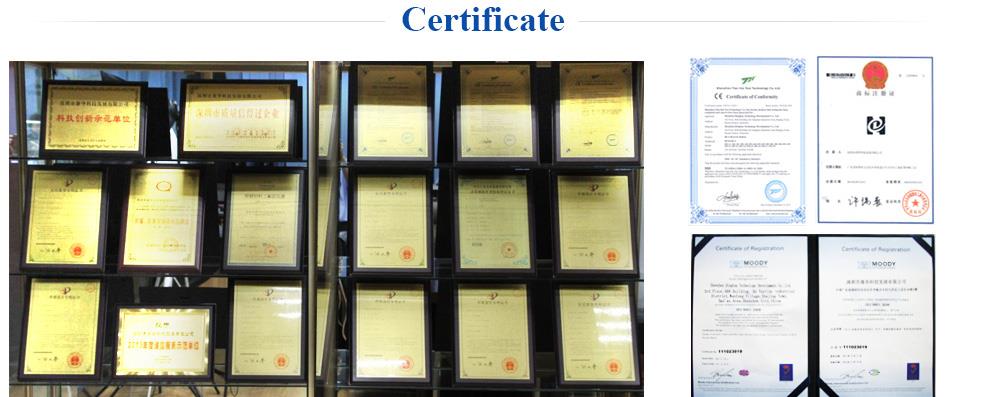

5. Daim ntawv pov thawj ntawmBGA Chip Reballing Thiab Rework

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua kom zoo tshaj qhov system, Dinghua muaj

dhau ISO, GMP, FCCA, C-TPAT ntawm qhov chaw kuaj ntawv pov thawj.

6. Kev xa khoom rauBGA Chip Reballing Thiab Rework

DHL / TNT / FEDEX. Yog tias koj xav tau lwm lub sijhawm shipping, thov qhia rau peb. Peb yuav txhawb koj.

7. Cov nqe lus them nqi

Hloov chaw hauv txhab nyiaj, Western Union, Credit Card.

Thov qhia rau peb yog tias koj xav tau lwm yam kev txhawb nqa.

11. Muaj kev paub txog

Qhov kub tsis kam ntawm PCB Circuit Board yog dab tsi? Yuav ua li cas koj ntsuas qhov kub tsis kam ntawm PCB Circuit Board?

Cov no yog cov lus nug ntau los ntawm cov neeg siv khoom. Cov ntaub ntawv hauv qab no yuav muab cov lus teb ntxaws.

Ua ntej:Qhov siab tshaj plaws kub tsis kam ntawm PCB Circuit Board yog dab tsi, thiab lub sij hawm ntawm qhov kub thiab txias yog dab tsi?

Qhov kub siab tshaj plaws ntawm PCB board yog 300 degrees Celsius rau 5-10 vib nas this. Rau cov hlau lead-dawb yoj soldering, qhov kub yog li 260 degrees Celsius, thaum rau cov hlau lead, nws yog 240 degrees Celsius.

Thib ob:Thaum tshav kub kub Resistance Test

Kev npaj:Circuit Court board ntau lawm board

1.Sample tsib 10x10 cm substrates (los yog plywood, tiav boards); xyuas kom lawv muaj tooj liab substrates yam tsis muaj blistering los yog delamination:

- Substrate: 10 lub voj voog lossis ntau dua

- Plywood: Tsawg CTE, 150, 10 cycles lossis ntau dua

- Cov khoom siv HTg: 10 lub voj voog lossis ntau dua

- Cov khoom siv ib txwm: 5 lub voj voog lossis ntau dua

- Finished Board:

Tsawg CTE, 150: 5 cycles lossis ntau dua

Cov khoom siv HTg: 5 lub voj voog lossis ntau dua

Cov khoom siv li qub: 3 lub voj voog lossis ntau dua

2.Teeb qhov kub ntawm lub tin cub rau 288 ± 5 degrees Celsius thiab siv kev sib cuag kub ntsuas rau calibration.

3. Ua ntej, siv txhuam txhuam los siv cov flux rau saum npoo ntawm lub rooj tsavxwm. Tom qab ntawd, siv cov hlua los tso cov ntawv xeem rau hauv lub qhov cub tawg. Tom qab 10 vib nas this, tshem nws thiab txias rau chav tsev kub. Saib xyuas seb puas muaj npuas tawg; qhov no suav ua ib lub voj voog.

4.Yog pom tias foaming lossis tawg tau pom thaum lub sijhawm kuaj pom, nres qhov kev tshuaj ntsuam immersion tin thiab tam sim ntawd pib qhov tawg point tsis ua haujlwm hom (F / M). Yog tias tsis pom muaj teeb meem, txuas ntxiv mus kom txog thaum qhov tawg tshwm sim, nrog rau 20 lub voj voog ua qhov kawg.

5.Txhua cov npuas yuav tsum tau muab txiav rau kev tshuaj xyuas kom paub qhov chaw pib cov ntsiab lus, thiab cov duab yuav tsum tau muab coj los ua.

Qhov kev taw qhia no muab cov kev paub yooj yim txog kev ntsuas kub thiab kub ua haujlwm rau PCB Circuit Boards. Peb vam tias nws yuav pab tau txhua tus. Peb yuav txuas ntxiv muab kev paub ntau ntxiv thiab cov ntaub ntawv tshiab hais txog PCB Circuit Board tsim, tsim khoom, thiab lwm yam. Yog tias koj xav paub ntau ntxiv txog kev paub txog PCB Circuit Board, thov ua raws li qhov chaw no.