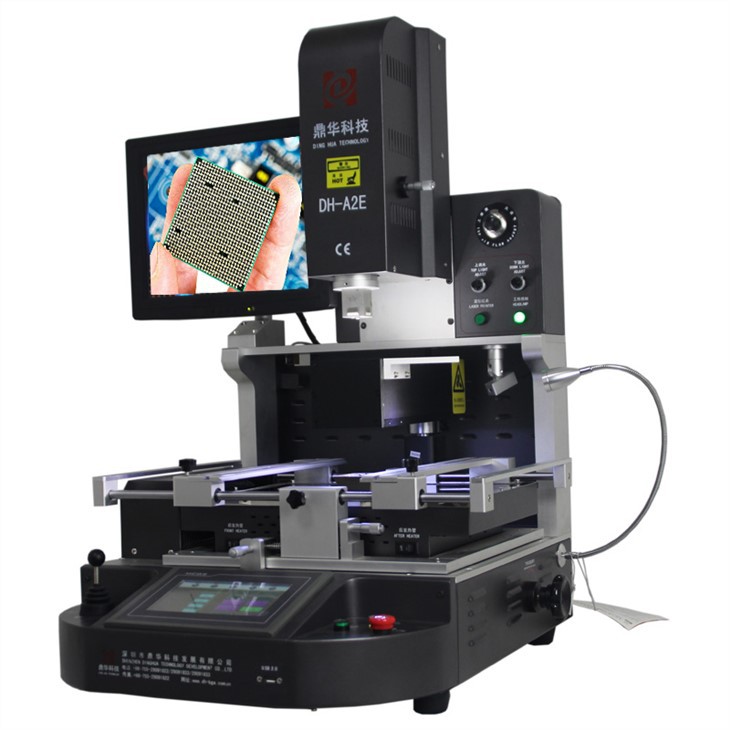

DH-A2E Tsis Siv Neeg BGA Rework Chaw nres tsheb

1.Full Automatic Optical Alignment BGA Rework Chaw nres tsheb.

2. Cua kub thiab IR

3.Hom: Dinghua Technology

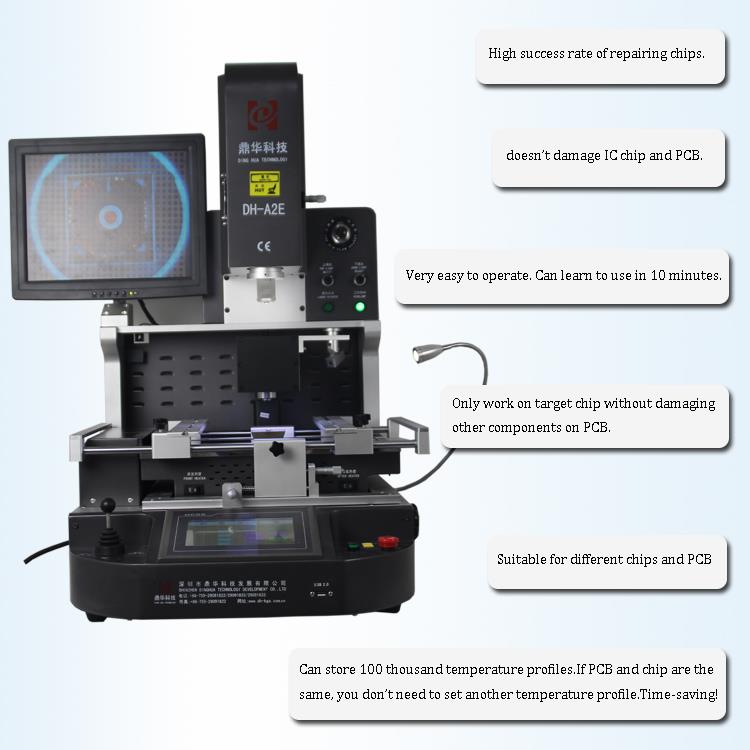

4.Advantages: Kev ua tiav zoo ntawm kev kho.

Hauj lwm lawm

DH-A2E Tsis Siv Neeg BGA Rework Chaw nres tsheb

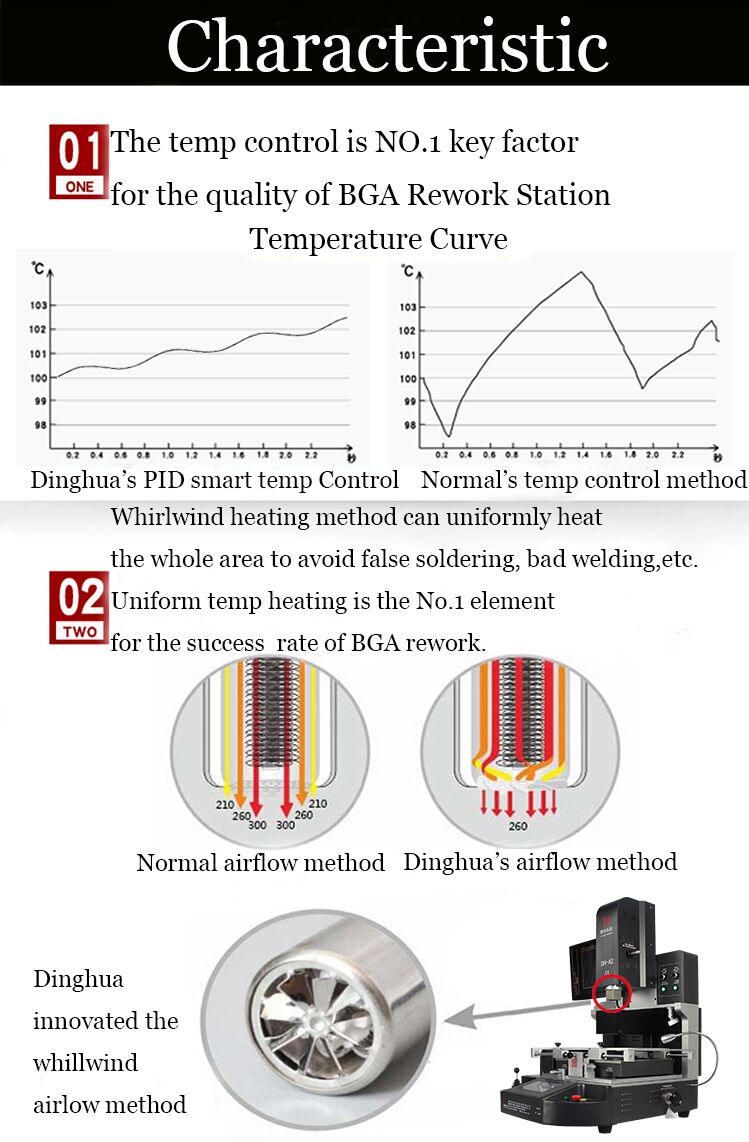

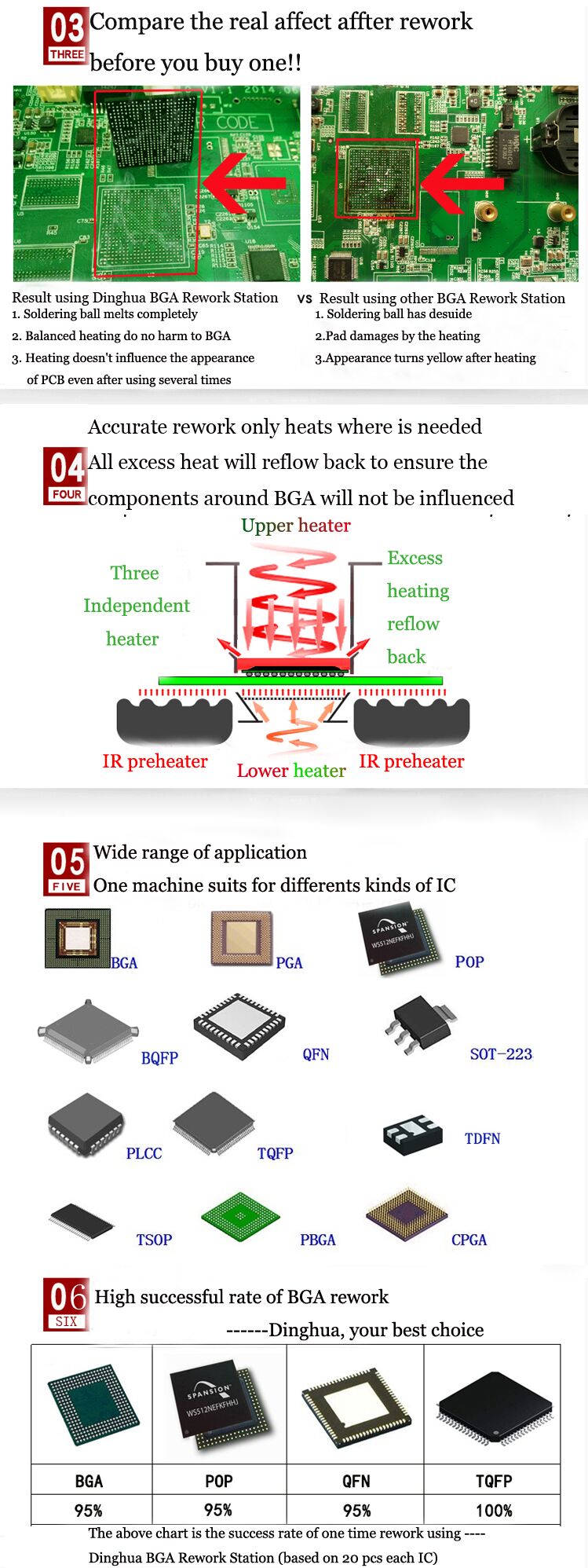

1.Khoom nta ntawm Kub Cua BGA Tshuab Rework Chaw nres tsheb

• Muaj kev vam meej ntawm kev kho chip-theem. Desoldering, mounting thiab soldering txheej txheem yog tsis siv neeg.

• Kev sib haum xeeb yooj yim.

•Ceramic tempered iav tiv thaiv motherboard los ntawm deformation.

• Peb tus kheej kub cua sov + PID tus kheej qhov chaw hloov kho, qhov tseeb kub yuav nyob ntawm ± 1 degree

• Ua hauv lub tshuab nqus tsev twj, khaws thiab tso BGA chips.

2.Specification ntawm Cua KubDH-A2E Tsis Siv Neeg BGA Rework Chaw nres tsheb

3.Cov ntsiab lus ntawm Infrared DH-A2E Tsis Siv Neeg BGA Rework Chaw nres tsheb

4.Vim li cas xaiv peb qhov chaw laser DH-A2E Tsis Siv Neeg BGA Rework Chaw Nres Tsheb?

5.Certificate of Optical alignment DH-A2E Automatic BGA Rework Station

6.Packing daim ntawv teev npentawm CCD Lub Koob Yees Duab DH-A2E Tsis Siv Neeg BGA Rework Chaw Nres Tsheb

7. Kev xa khoom ntawm CCD lens DH-A2E Tsis Siv Neeg BGA Rework Chaw nres tsheb

Peb xa lub tshuab ntawm DHL / TNT / UPS / FEDEX, uas yog ceev thiab nyab xeeb. Yog tias koj xav tau lwm cov nqe lus ntawm kev xa khoom,

thov koj xav qhia rau peb paub.

8. Cov nqe lus them nqi.

Hloov txhab nyiaj, Western Union, Credit card.

Peb yuav xa lub tshuab nrog 5-10 kev lag luam tom qab tau txais cov nyiaj them poob haujlwm.

9. Kev qhia ua haujlwm rau DH-A2E Tsis Siv Neeg BGA Rework Chaw nres tsheb

10. Hu rau peb kom teb tam sim thiab tus nqi zoo tshaj.

Email: John@dh-kc.com

MOB/WhatsApp/Wechat: +86 15768114827

Nyem qhov txuas ntxiv kuv WhatsApp:

https://api.whatsapp.com/send?phone=8615768114827

10.Kev paub txog

SMT tivthaiv muaj stencil qhib qhov loj thiab cov duab uas zoo ib yam nrog lub ncoo thiab qhib hauv 1: 1 yam.

Hauv cov xwm txheej tshwj xeeb, qee qhov tshwj xeeb SMT Cheebtsam muaj cov kev cai tshwj xeeb rau qhov loj thiab cov duab ntawm qhov qhib stencil.

2 Tshwj xeeb SMT tivthaiv stencil qhib 2.1 CHIP tivthaiv: 0603 lossis ntau dua CHIP tivthaiv, txhawm rau ua haujlwm zoo

tiv thaiv tiam ntawm tin hlaws. 2.2 SOT89 Cheebtsam: Vim yog qhov sib txawv me me ntawm cov ntaub qhwv thiab cov khoom siv,

nws yog ib qho yooj yim los tsim cov teeb meem zoo xws li cov khoom siv solder. 2.3 SOT252 tivthaiv: Txij li thaum SOT252 muaj lub ncoo loj,

nws yog ib qho yooj yim los tsim tin hlaws dai, thiab cov reflow soldering nro ua rau ib tug loj txav. 2.4IC: A. Rau tus qauv tsim qauv,

ib qho IC nrog PITCH ntawm=0.65 hli muaj qhov qhib dav ntawm 90% ntawm qhov dav ntawm lub ncoo thiab qhov ntev tas mus li. B. Rau tus qauv pad tsim,

PITCH "= 005mm IC, vim nws qhov me me PITCH, yog ib qho yooj yim rau choj, stencil qhib hom muaj tib qhov ntev kev taw qhia, qhib

dav yog {{0}}.5PITCH, thiab qhov qhib dav yog 0.25mm. 2.5 Lwm qhov xwm txheej: Thaum lub ncoo loj dhau, feem ntau ib sab yog loj dua 4 hli thiab

sab nraud tsis tsawg tshaj li 2.5 hli, txhawm rau tiv thaiv kev tsim cov tin hlaws thiab cov khoom txav los ntawm kev nro, cov mesh

qhib tau pom zoo kom txais yuav txoj kab sib faib kab. Daim phiaj dav yog 0.5mm thiab daim phiaj loj yog 2 hli, uas tuaj yeem muab faib sib npaug

los ntawm qhov loj me. Kev luam ntawv stencil qhib cov duab thiab qhov loj me: Rau kev sib dhos yooj yim PCB, cov tshuab nplaum yog nyiam. Kev faib tawm

yog nyiam. CHIP, MELF, SOT cov khoom yog luam tawm los ntawm stencil, thiab IC yog siv kom tsis txhob stenciling. Ntawm no, tsuas yog CHIP, MELF,

SOT luam ntawv stencils raug pom zoo rau qhov qhib qhov loj thiab qhib cov duab. 1. Ob txoj kab pheeb ces kaum qhov chaw yuav tsum tau qhib ntawm

kab pheeb ces kaum ntawm stencil, thiab FIDUCIAL MARK taw tes qhib yuav tsum raug xaiv. 2. Cov qhov qhib yog cov strips ntev. Kev tshuaj xyuas txoj kev

1) Txheeb xyuas qhov qhib thiab nruab nrab ntawm qhov ncab ncab los ntawm kev tshuaj xyuas qhov muag. 2) Txheeb xyuas qhov tseeb ntawm stencil qhib los ntawm PCB qhov chaw.

3) Txheeb xyuas qhov ntev thiab qhov dav ntawm qhov qhib stencil thiab smoothness ntawm phab ntsa ntawm lub qhov thiab qhov chaw ntawm cov ntawv hlau nrog ib tug

kawm tiav high power microscope. 4) Lub thickness ntawm cov ntawv hlau raug txheeb xyuas los ntawm kev txheeb xyuas qhov tuab ntawm cov nplaum nplaum tom qab luam ntawv,

uas yog, qhov tshwm sim tau txheeb xyuas. Xaus Lub tshuab tsim stencil xav tau lub sijhawm sim thiab tswj, thiab kev luam ntawv zoo

tswj. PPM ntawm SMT vuam qhov tsis zoo yog txo los ntawm 1300ppm txog 130ppm. Vim txoj kev loj hlob ntawm lub

ntim cov kev taw qhia ntawm cov khoom siv hluav taws xob niaj hnub, cov kev xav tau siab dua kuj tau muab tso rau ntawm kev tsim cov hlau mesh. Nws yog ib lub ntsiab lus uas peb

yuav tsum tsom ntsoov rau yav tom ntej.

Yam khoom:

Cua kub reflow soldering tshuab

Motherboard kho tshuab

SMD micro Cheebtsam daws

LED SMT rework soldering tshuab

IC hloov tshuab

BGA nti reballing tshuab

BGA rov

Soldering cov khoom siv

IC nti tshem tawm tshuab

BGA rework tshuab

Cua kub solder tshuab

SMD rework chaw nres tsheb

IC tshem tawm cov cuab yeej