Siab Tsis Siv Neeg IC QFN Reballing Tshuab Rau PCBA

BGA / SMD rework chaw nres tsheb DH-A2E muaj tsis siv neeg kho qhov muag CCD nrog ib tug nti feeder, cia li soldering thiab desoldering rau ib feem ntawm PCBA ntawm lub computer, xov tooj ntawm tes, GPS tracker, Projector formater thiab cov tswj mainboard ntawm lub tsheb.

Hauj lwm lawm

-

Cov khoom qhia

Optical CCD thiab chip feeder:

-

Lub optical CCD yog cia li khiav rau kev yees duab ntawm ib qho screen

-

Lub chip feeder tuaj yeem khiav rau cov khoom siv hloov pauv lossis tuaj tos

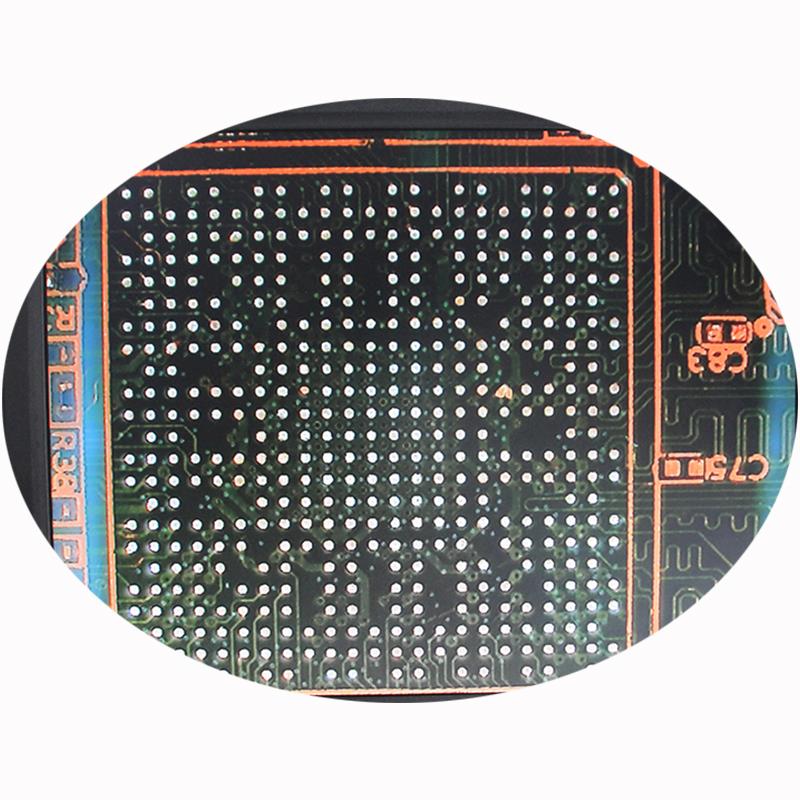

Nthuav qhov screen rau duab

-

15 ntiv tes, HD rau cov khoom siv nrog cov dot dot 0.1 * 0.1mm duab rau

-

muaj RGR, ib xim rau ib feem, ib xim rau motherboard.

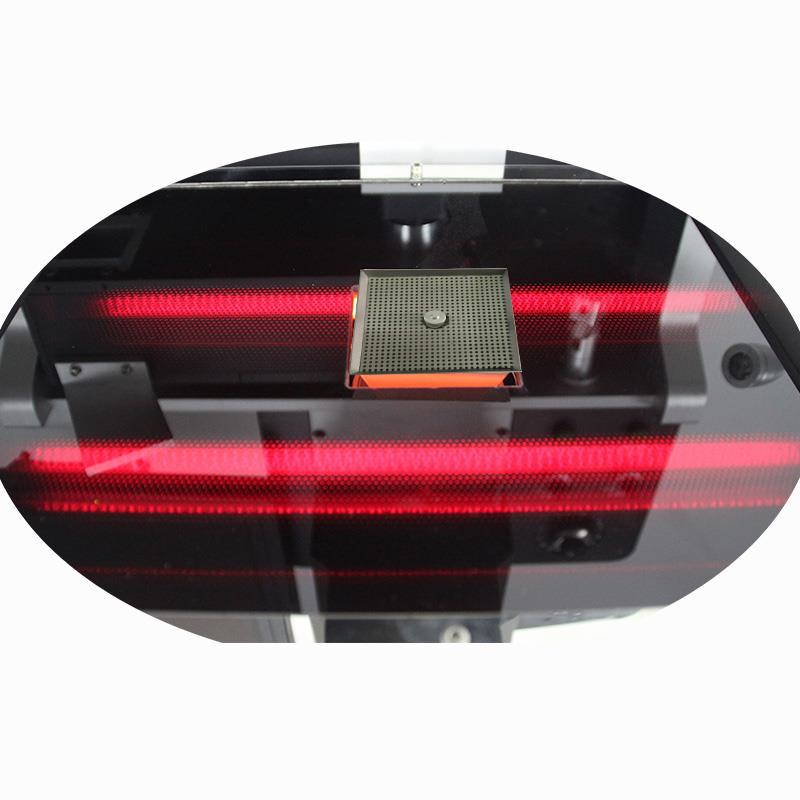

Ib qho loj IR preheating cheeb tsam rau feem ntau ntawm lub mainboard

-

Iav-shield rau IR, uas ua rau tib neeg ua haujlwm thiab tiv thaiv tiv thaiv

-

Sib npaug kub rau tag nrho cov motherboard.

Adjustable nyees khawm los yog pob qhov rooj

-

Sab saum toj airflow khawm hloov kho rau lub microchip soldering

-

Sab saum toj / down lub teeb kho rau cov duab tshem tawm ntawm lub vijtsam saib.

Lub joystick rau saum taub hau kho

-

Thaum phau ntawv qhia, lub taub hau saum toj kawg nkaus tuaj yeem txav mus los ntawm nws

-

Thawj zaug teeb tsa PCBA txoj haujlwm, nws yuav tsum tau siv.

Ib qho kev ua haujlwm interface ntawm lub touchscreen

-

Ib qho tseem ceeb pib kom txog thaum soldering lossis desoldering tiav

-

hloov lossis txuag tau yooj yim rau kev teeb tsa.

Parameters ntawm lub tshuab reballing:

| Fais fab mov | 110-250V 50/60Hz |

| zog | 5400W |

| Tsis siv neeg optical CCD system | cia li tawm mus thiab rov qab nrog lub chip feeder |

| Fais fab mov | Meanwell, raws li lub npe hu |

| Motors ntawm cov kiv cua txias | Taida ua nyob rau hauv Taiwan |

| Touchscreen | MCGS, rhiab thiab HD |

| Cov khoom siv tau siv | BGA, IC, QFN, POP thiab lwm yam. |

| Qhov chaw min |

0.15 hli |

FAQ ntawm High automatic IC QFN reballing tshuab rau PCBA ntawm lub computer soldering thiab desoldering

Q: Dab tsi yog qhov voltage kuv tuaj yeem siv rau?

A: los ntawm 110V ~ 250V, xaiv tau rau ntau lub teb chaws siv.

Q: Kuv tuaj yeem ua dab tsi ntawm BGA reballing tshuab?

A: soldering, desoldering rau ib feem, xws li, BGA, QFN, IC thiab POP thiab lwm yam.

Q: qhov twg yog nws tsim?

A: Ua nyob rau hauv Suav teb -- nqi-zoo thiab zoo

Q: Koj lub Hoobkas tuaj yeem ua dab tsi ntxiv?

A: tshwj tsis yog BGA rework chaw nres tsheb, peb kuj tuaj yeem tsim tsis siv neeg ntsia hlau xauv tshuab, chaw nres tsheb soldering thiab lwm yam.

Cov kev paub txog ntawm lub tshuab tsis siv neeg IC QFN reballing tshuab rau PCBA ntawm lub computer soldering thiab desoldering

Lub hom phiaj ntawm chav kawm vuam yog muab cov neeg teb xov tooj nrog cov kev xav siab tshaj plaws ntawm txhua txoj kev vuam niaj hnub

siv phau ntawv welders, cua kub welders,IR welders, preheaters. Hoob no yog ib feem ntawm qhov theoretical thiab kev xyaum uas tus menyuam kawm tautam sim ntawd sim nrog txhua hom ntawmvuam qhia nyob rau hauv qhov kev pab cuam.

Cov evolution ntawm cov khoom siv hluav taws xob tau dhau los ua qhov tseem ceeb, nthuav qhia nws cov khoom me me

tsos hauv pob thiab nrog tus pin siabsuav; txoj kev txhim kho no tau coj mus rau txoj kev loj hlob ntawm

nce complex (thiab kim) reworkingtshuab. Ib qho piv txwv raug muab los ntawm BGApob thiab cov

ntsig txog µBGA thiab CSP versions uas qhia txog cov teeb meem ntawm qib tshuaj xyuas ntawm cov vuam pob qij txha, uas nws ntseeg tau

yog rendered precariouslos ntawm qhov tsim tau ntawm qhov tsis muaj dab tsi. Qhov zoo ntawm phau ntawv welding nyob ntawm qhov sib txawv ntawm qhov sib txawv, tus neeg teb xov tooj muaj peev xwm, xaim zoo, kev ua tau zoo thiab kev ua haujlwm ntawm lubvuam chaw nres tsheb. Kev tuav vuam kuj tseem cuam tshuam los ntawm kev hloov pauv ntawm lub ntiaj teb thev naus laus zis uas nyob ib puag ncig nws thiab nws yuav tsum teb nrog ib txwm muaj tswv yim tshiab.kev daws teeb meem. Hauv

kev tuav vuam kev ua haujlwm, yeej ib txwm muaj kev sib raug zoo-kev sib raug zoo uas txuas tus neeg teb xov tooj lub peev xwm thiab kev ua haujlwm ntawm vuam lossis rov ua haujlwm.chaw nres tsheb. Txawm tias qhov chaw vuam zoo tshaj plaws tuaj yeem ua tsis muaj dab tsi tawm tsam tus neeg teb xov tooj tsis muaj kev txawj ntse. Ntawm qhov tod tes, tus neeg teb xov tooj nrog kev txawj ntse thiab kev kawm, nrog kev sib txuas zoo heevsystem, muaj peev xwm rov ua haujlwm txawm tias qhov xwm txheej xav tau tshaj plaws, yuav tsis muaj peev xwm sib npaug cov qhov khoob uas tsim cov txheej txheem vim tias lub hom phiaj ntawm cov txheej txheem yog thawj-pass yield thiab recovering thaum lub sij hawm rework yog ib tug nqi thiab tsis yog ib tug ntxiv. Txawm li cas los xij, qib siab thev naus laus zis

ntawm cov cuab yeej siv tau ua rau muaj txiaj ntsig zoo ntawm cov khoom sivkev khiav hauj lwm vim nws tso cai rau kev tswj zoo ntawm feem ntau ntawm

cov variables koom. Qhov no yog ib qho ntawm cov kev txhawb siab uas tau thawb mus rau cov chaw nres tsheb nrog zoo heev

kev ua yeeb yam.

lwm qhov yog qhov yuav tsum muaj cov tshuab ua haujlwm zoo. Cov thermal hloov pauv tau zoo tso cai rov ua dua vuam, nrog rau qhov ntsuas kub ruaj khov, tsis muaj oscillations vim qeebrov qab thermal zog. Hauv kev ua haujlwm rov ua haujlwm, plaub

Cov theem tuaj yeem txheeb xyuas tau: kev tshem tawm thiab tshem tawm cov khoom siv, kev tu cov ntaub qhwv, qhov chaw

ntawm cov khoom tshiab thiab nws cov vuam. Nyob rau hauv cov ntaub ntawv ntawm complex Cheebtsam xws li cov teej tug mus rau lub cheeb tsam array

tsev neeg, serigraphy los yog dispensing ntawm solder paste kujxav tau. Ib qho ntawm cov teeb meem loj uas tau ntsib nyob rau theem ua haujlwm yog qhov kev tso kawm ntawm cov mini-stencils siv los tso cov muab tshuaj txhuam rau ntawm cov ntaub qhwv ntawm cov khoom siv rov ua dua tshiab.

Qhov kev ua haujlwm no, yog tias tsis ua kom raug, kuj tseem cuam tshuam rau cov txheej txheem rov ua dua thiab sib koom ua ke. Lwm qhov teeb meem tshwm sim tshwm sim ncaj qha hauv kev khotxheej txheem thiab muab tau los ntawm qhov nce ntawm tus naj npawb ntawm cov terminals thiab txo lawv cov pace. Feem ntau cov PCB kuj txo qhov loj me, txo qhov chaw muaj txiaj ntsig ntau dua raucuam tshuam nrog kev pheej hmoo ntawm kev cuam tshuam nrog cov khoom nyob ib puag ncig.