Kub Cua BGA Rework Chaw nres tsheb

1.Automatic desoldering, Mounting thiab Soldering, tsis siv neeg khaws nti thaum desoldering tiav. 2.CE daim ntawv pov thawj pom zoo. Ob chav tiv thaiv (Overheating guard + xwm ceev nres muaj nuj nqi.)

Hauj lwm lawm

Kub Cua BGA Rework Chaw nres tsheb

1.Application ntawm Kub Cua BGA Rework Chaw nres tsheb

Motherboard ntawm lub computer, ntse xov tooj, laptop, MacBook logic board, digital koob yees duab, cua txias, TV thiab lwm yam

electronic equipments los ntawm kev kho mob kev lag luam, kev lag luam kev sib txuas lus, kev lag luam tsheb, thiab lwm yam.

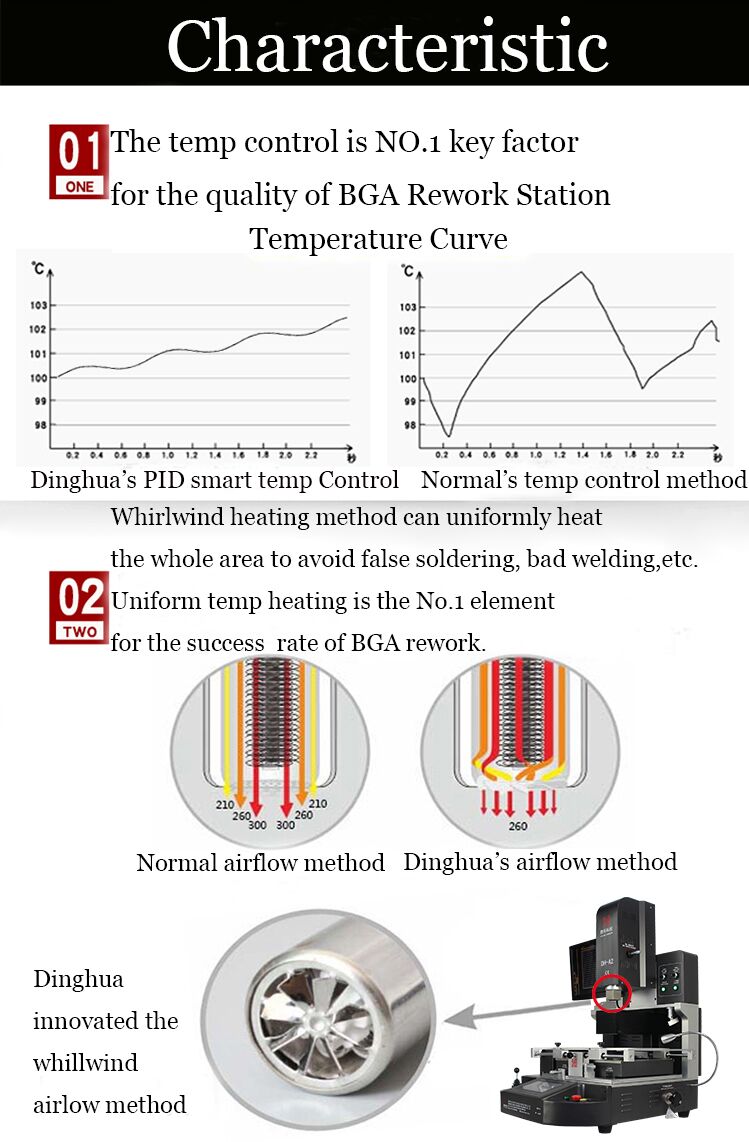

Haum rau ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED nti.

2.Product Nta ntawm Kub Cua BGA Rework Chaw Nres Tsheb

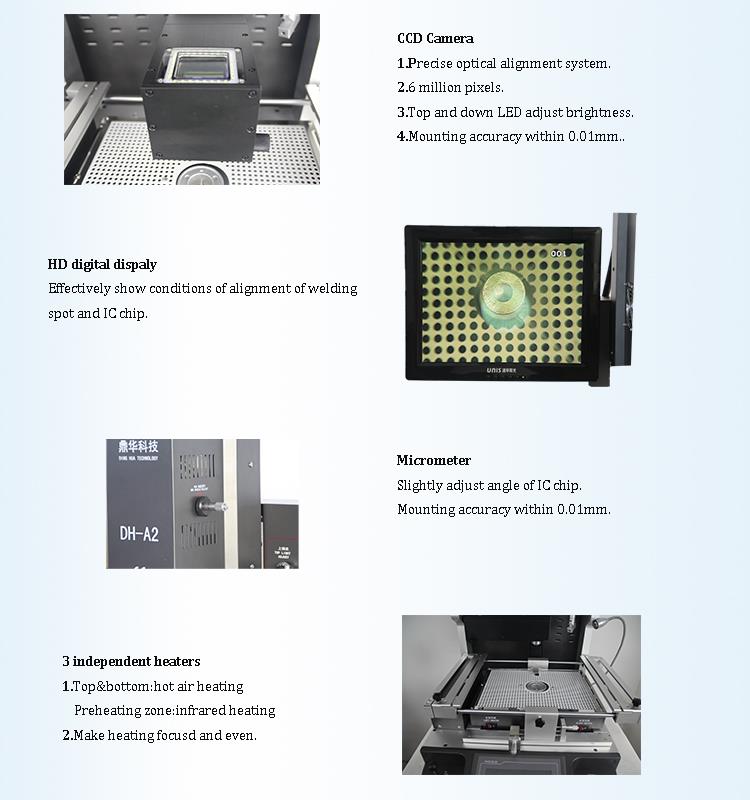

- Precise optical alignment system

- CCD lub koob yees duab nthuav dav txog li 200x, nrog rau sab saum toj/down lub teeb ci ci kho muaj nuj nqi, mounting raug nyob rau hauv 0.01 hli.

- Tsis siv neeg desoldering, Mounting thiab Soldering, tsis siv neeg khaws nti thaum desoldering tiav.

- Los nrog 5 qhov sib txawv ntawm Nozzles: Upper 31 * 31mm, 38 * 38mm, 41 * 41mm. Hauv qab 34 * 34mm, 55 * 55mm

- Lub Hwj Chim Loj Hla Dej Ntxuam, Txias Lub Pcb sai heev, tiv thaiv nws los ntawm deformation.

3.Specification ntawm Kub Cua BGA Rework Chaw nres tsheb

| Hwj chim | 5300w |

| Lub tshuab cua sov sab saum toj | Cua kub 1200w |

| Hauv qab lub rhaub | Cua kub 1200W. Infrared 2700w |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | Ktype thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGA chip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

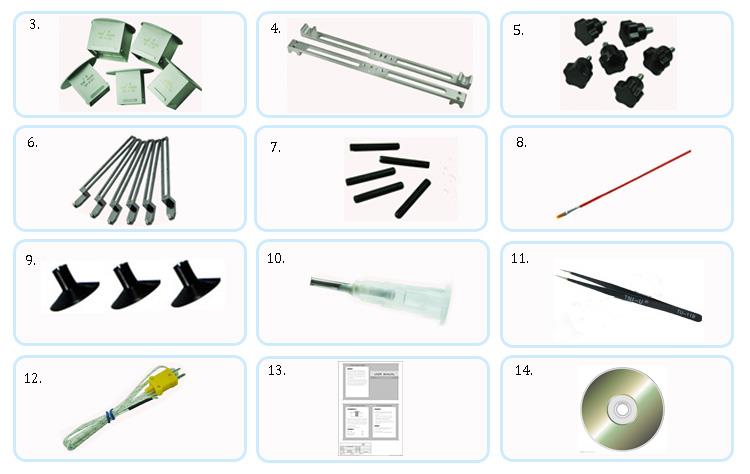

4.Cov ntsiab lus ntawm Kub Cua BGA Rework Chaw nres tsheb

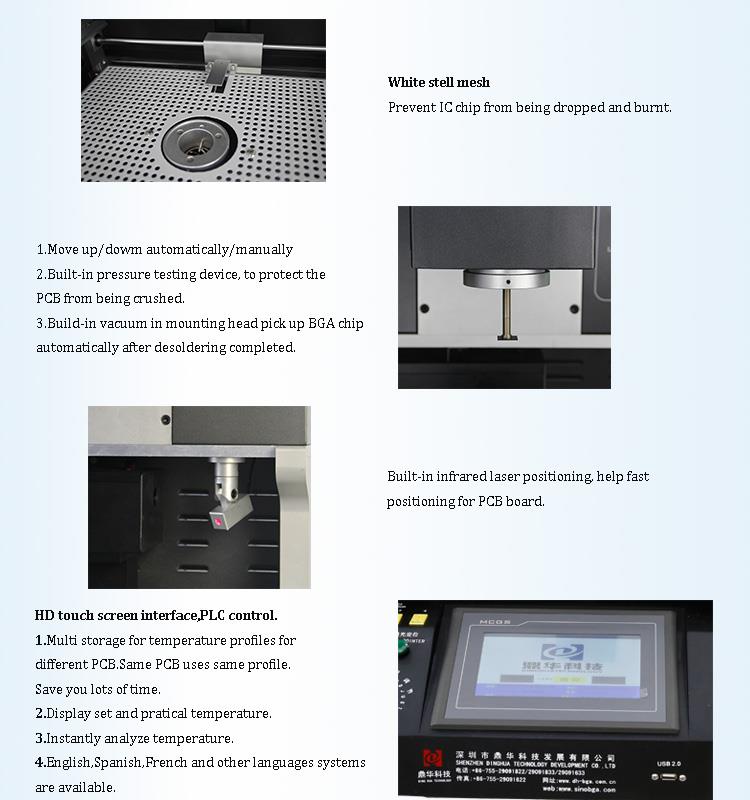

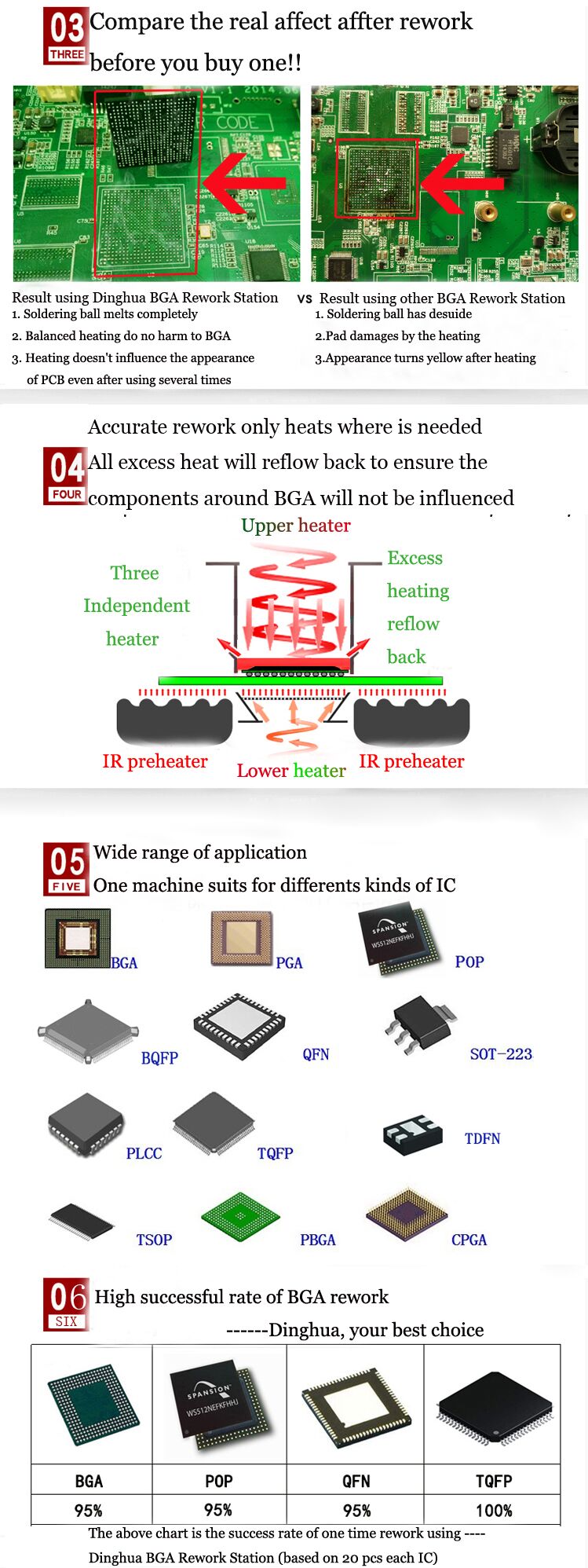

5.Vim li cas thiaj xaiv Peb Qhov Chaw Nres Cua Kub BGA Rework?

6.Certificate of Kub Cua BGA Rework Chaw nres tsheb

7.Packing & Shipping ntawm Kub Cua BGA Rework Chaw nres tsheb

8. Kev Paub Txog

Dab tsi yog qhov zoo ntawm SMT pob?

Surface Mount Technology (SMT) yog hais txog cov txheej txheem ntawm kev muab cov khoom me me los yog cov ntawv ua qauv tsim nyog rau kev sib dhos saum npoo mus rau lub rooj tsav xwm luam tawm (PCB) raws li qhov yuav tsum tau ua hauv Circuit Court. Cov khoom no ces sib sau ua ke los ntawm cov txheej txheem soldering xws li reflow soldering lossis yoj soldering los tsim cov khoom siv hluav taws xob ua haujlwm.

Thawj qhov sib txawv ntawm SMT thiab Through-Hole Technology (THT) yog nyob rau hauv txoj kev mounting. Ntawm ib txwm THT PCB, cov khoom siv thiab cov pob qij txha yog nyob rau sab nraud ntawm lub rooj tsavxwm. Hauv qhov sib piv, ntawm SMT PCB, ob qho tib si cov pob qij txha thiab cov khoom siv nyob rau tib sab. Yog li ntawd, los ntawm qhov ntawm lub rooj tsavxwm SMT tsuas yog siv los txuas cov txheej hauv Circuit Court, uas ua rau muaj qhov tsawg thiab tsawg dua. Qhov no tso cai rau kom muaj kev sib dhos ntau dua ntawm PCB.

SMT cov khoom sib txawv ntawm THT cov khoom feem ntau hauv lawv cov ntim. SMT tej pob khoom yog tsim los tiv taus kub thaum lub sij hawm soldering, yuav tsum tau cov khoom thiab substrates kom muaj ib tug sib xws coefficient ntawm thermal expansion. Cov yam ntxwv no yog qhov tseem ceeb hauv kev tsim khoom.

Cov yam ntxwv tseem ceeb ntawm SMT Process Technology

SMT sib txawv ntawm THT nyob rau hauv cov nqe lus ntawm kev sib sau ua ke: SMT koom nrog "so" cov khoom rau ntawm lub rooj tsavxwm, thaum THT koom nrog "plug" cov khoom los ntawm qhov. Qhov sib txawv kuj muaj pov thawj nyob rau hauv lub substrate, daim ntawv tivthaiv, solder joint morphology, thiab kev sib dhos txheej txheem.

Qhov zoo ntawm Kev Xaiv Txoj Cai SMT Pob

- Siv tau zoo ntawm PCB Chaw: SMT txuag thaj chaw PCB tseem ceeb, tso cai rau kev tsim kom muaj qhov ntom ntom dua.

- Txhim kho hluav taws xob ua haujlwm: Cov kab hluav taws xob luv luv txhim kho kev ua haujlwm.

- Kev tiv thaiv ib puag ncig: Lub ntim tiv thaiv cov khoom los ntawm lwm yam xws li ya raws.

- Txhim khu kev sib txuas: SMT ua kom muaj kev sib txuas lus ruaj khov thiab ruaj khov.

- Txhim kho cua sov Dissipation: Ua kom yooj yim rau kev tswj cov cua sov, kev sim, thiab cov teeb liab kis tau zoo.

Qhov tseem ceeb ntawm SMT Tsim thiab Kev Xaiv Cov Txheej Txheem

Kev xaiv thiab tsim ntawm SMT Cheebtsam ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom lag luam tag nrho. Thaum lub sij hawm lub system architecture thiab cov ncauj lus kom ntxaws Circuit Court tsim theem, designers txiav txim siab qhov hluav taws xob kev ua tau zoo thiab kev ua hauj lwm yuav tsum tau ntawm lub Cheebtsam. Nyob rau hauv SMT tsim theem, kev txiav txim siab txog cov pob ntawv thiab cov qauv yuav tsum ua raws li cov khoom siv thiab cov txheej txheem muaj peev xwm, nrog rau tag nrho cov qauv tsim.

Dual Lub luag haujlwm ntawm Surface Mount Solder Joints

Surface mount solder joints ua haujlwm ob qho tib si raws li kev sib txuas ntawm cov tshuab thiab hluav taws xob. Kev xaiv tsim nyog ntawm cov pob qij txha ncaj qha cuam tshuam rau PCB tsim ntom ntom, kev tsim khoom, kev sim, thiab kev ntseeg tau.