DH-A2 BGA Rework Chaw nres tsheb

Yooj yim rau kev khiav lag luam.

Haum rau chips thiab motherboard ntawm ntau qhov sib txawv.

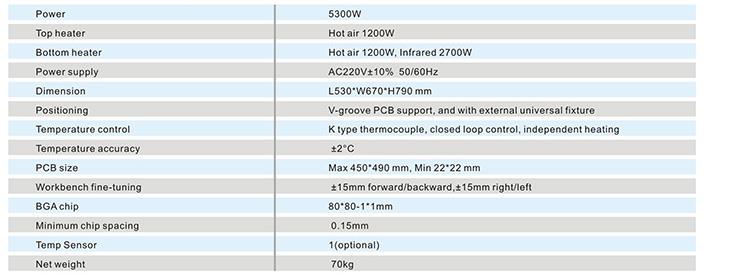

Kev ua tiav zoo ntawm kev kho.

Hauj lwm lawm

DH-A2 BGA Rework Chaw nres tsheb

1.Application Ntawm DH-A2 BGA Rework Chaw nres tsheb

Haum rau PCB sib txawv.

Motherboard ntawm lub computer, ntse xov tooj, laptop, MacBook logic board, cov koob yees duab, cua txias, TV thiab

lwm yam khoom siv hluav taws xob los ntawm kev kho mob kev lag luam, kev sib txuas lus kev lag luam, kev lag luam tsheb, thiab lwm yam.

Haum rau ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA,

LED nti.

2.Product Nta ntawm DH-A2 BGA Rework Chaw nres tsheb

• Desoldering, mounting thiab soldering txiav.

• Cov yam ntxwv ntawm qhov ntim siab (250} l / min), tsis tshua muaj siab (0.22kg / cm2), qis kub (220 degree) rov ua haujlwm tiav

guarantees BGA chips hluav taws xob thiab zoo heev soldering zoo.

• Kev siv cov twj ntsiag to thiab tsis tshua muaj siab hom cua tshuab tso cai rau kev tswj ntawm lub tshuab ua pa ntsiag to, cov cua ntws tuaj yeem

raug tswj kom 250 l / Min qhov siab tshaj plaws.

• Cov cua kub ntau lub qhov puag ncig qhov chaw txhawb nqa tshwj xeeb yog qhov tseem ceeb rau PCB loj thiab BGA nyob hauv nruab nrab ntawm

PCB. Tsis txhob txias soldering thiab IC-poob qhov xwm txheej.

• Kub profile ntawm cov cua kub hauv qab cua sov tuaj yeem ncav cuag li 300 degree, qhov tseem ceeb rau loj loj motherboard.

Lub caij no, lub tshuab cua sov sab saud tuaj yeem teeb tsa ua synchronized lossis ua haujlwm ywj pheej

3.Specification ntawm DH-A2 BGA Rework Chaw nres tsheb

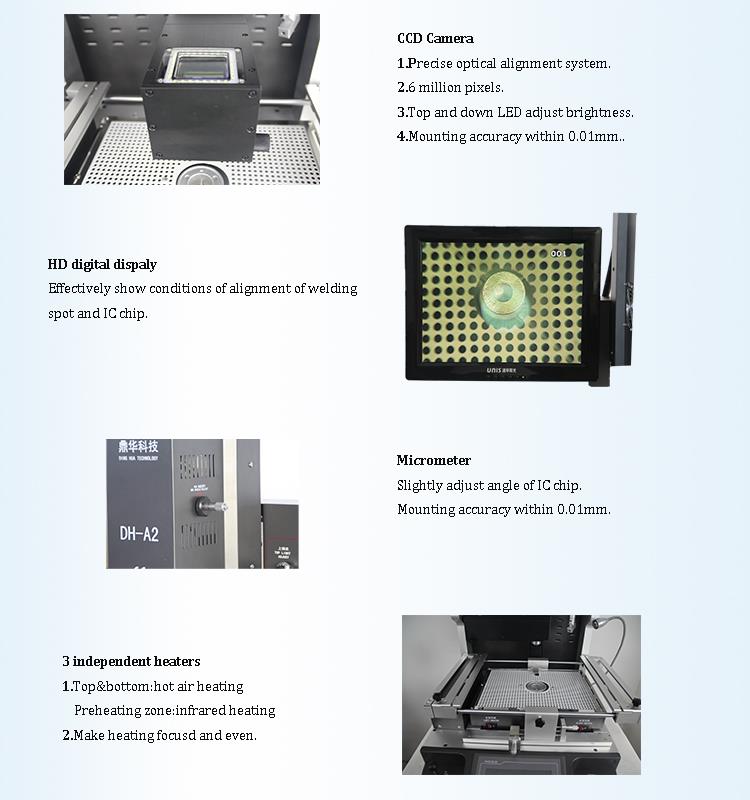

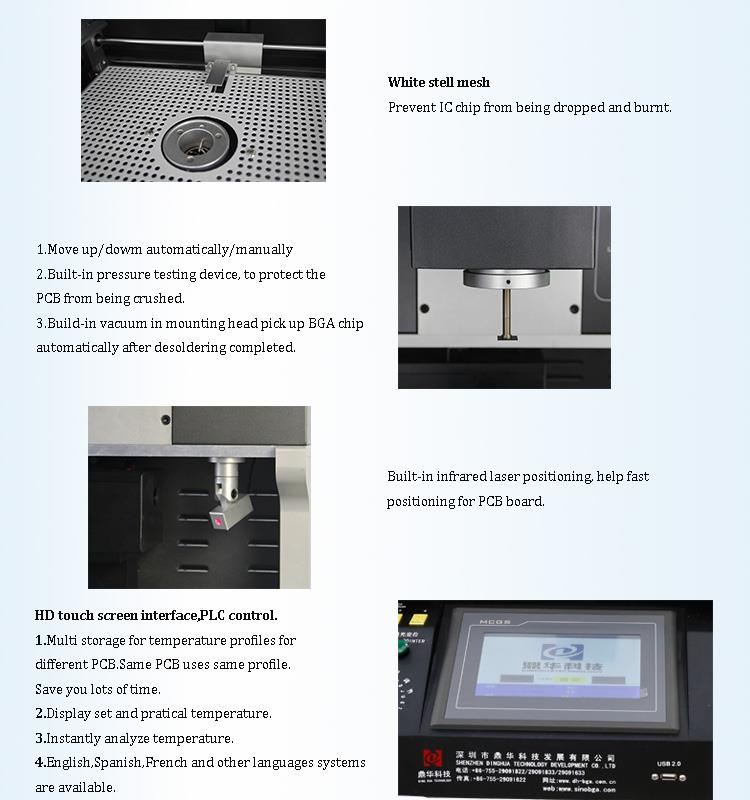

4.Cov ntsiab lus ntawm DH-A2 BGA Rework Chaw nres tsheb

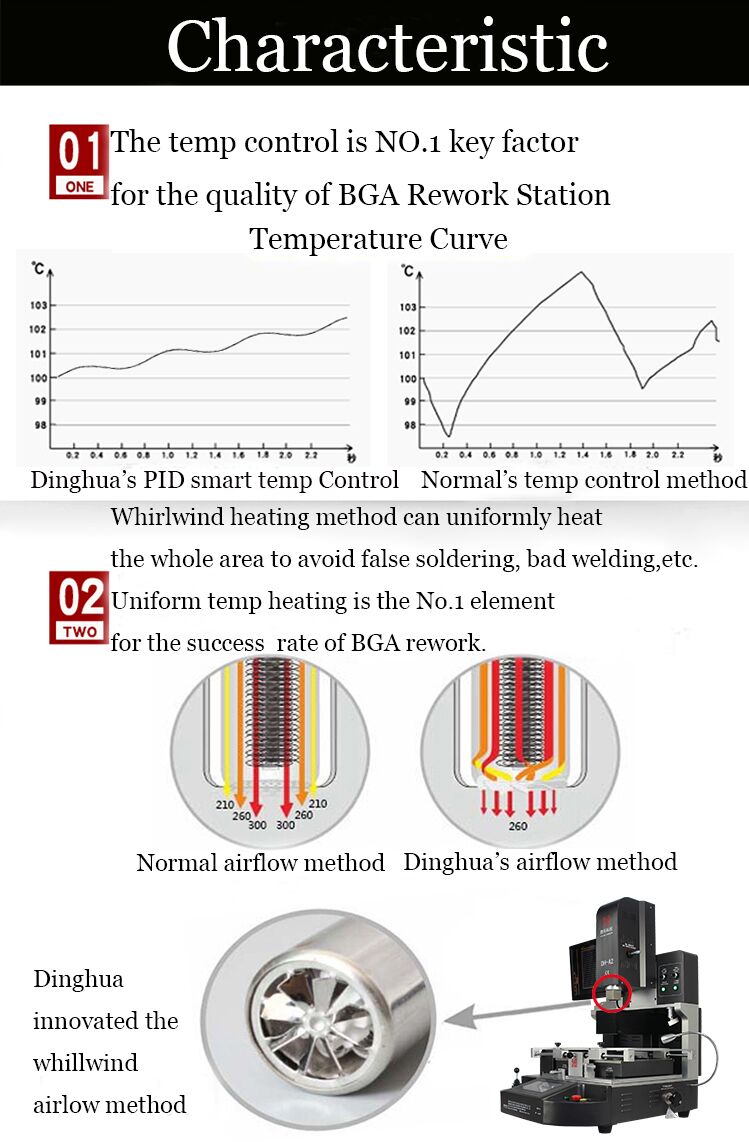

5.Vim li cas thiaj xaiv peb DH-A2 BGA Rework Chaw nres tsheb?

6.Certificate ntawm DH-A2 BGA Rework Chaw nres tsheb

7.Packing & Shipping ntawm DH-A2 BGA Rework Chaw nres tsheb

8.Related paub txogDH-A2 BGA Rework Chaw nres tsheb

•BGA vuam txheej txheem thev naus laus zis yog dab tsi?

Lub hauv paus ntsiab lus ntawm reflow soldering siv nyob rau hauv BGA soldering. Ntawm no peb qhia txog lub reflow mechanism ntawm cov pob solder thaum lub sij hawm soldering txheej txheem.

Thaum lub pob solder nyob rau hauv ib puag ncig rhuab, lub pob solder reflow muab faib ua peb theem:

Preheating:

Ua ntej, cov kuab tshuaj siv los ua kom tiav qhov xav tau viscosity thiab cov khoom siv tshuaj ntsuam luam ntawv pib evaporate, thiab qhov kub nce yuav tsum qeeb.

(kwv yees li 5 degree C ib ob) txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhuam nws

kev nyuaj siab. rhiab heev, yog tias qhov kub thiab txias sab nraud ntawm cov khoom siv nce nrawm heev, nws yuav ua rau tawg.

Lub flux (paste) yog nquag, tshuaj ntxuav tes pib, cov dej-soluble flux (paste) thiab cov dej tsis huv (paste) txhua tus muaj tib yam kev tu

kev txiav txim, tshwj tsis yog tias qhov kub thiab txias sib txawv me ntsis. Hlau oxides thiab tej yam kab mob raug tshem tawm ntawm cov hlau thiab solder hais rau

ua phooj ywg. Zoo metallurgical solder pob qij txha yuav tsum tau "huv" nto.

Raws li qhov kub thiab txias tseem nce ntxiv, cov khoom siv hluav taws xob tau yaj ua ntej sib cais thiab pib "teeb pom kev" txheej txheem ntawm liquefaction thiab nto suction.

Qhov no npog txhua qhov chaw ua tau thiab pib tsim cov pob qij txha.

Reflux:

Cov theem no yog qhov tseem ceeb tshaj plaws. Thaum ib tug solder particle yog kiag li melted, nws combines los ua ib tug kua tin. Thaum lub sij hawm no, nto nro

pib tsim qhov chaw ntawm lub solder fillet yog tias qhov sib txawv ntawm cov khoom siv lead ua thiab PCB ncoo tshaj 4 mils (1 mil=ib txhiab ib nti),

Nws yog qhov zoo tshaj plaws uas tus pin thiab lub ncoo sib cais vim qhov nro ntawm qhov chaw, uas ua rau lub tin taw tes qhib.

Txias cia:

Thaum lub sij hawm txias txias, yog tias qhov txias yog ceev, lub zog tin taw tes yuav loj dua me ntsis, tab sis nws yuav tsum tsis txhob ceev heev kom ua rau kub ntxhov hauv

cov khoom.