2 Cov Cuab Yeej Cuab Yeej Kov Screen BGA Rework Chaw Nres Tsheb

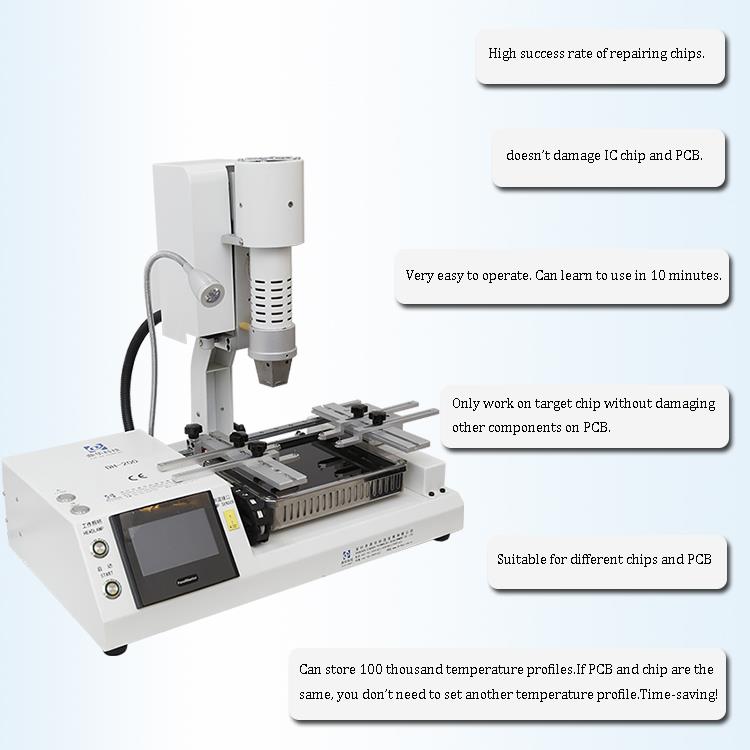

Lub rework system yuav tsum ua kom sov ib qho chaw nqaim heev ntawm lub rooj tsavxwm. DH-200 BGA rework chaw nres tsheb tuaj yeem ua tau raws nraim thiab yooj yim. Nws yog nrog kev paub txog kev paub zoo heev. Tsis tas li ntawd rau qhov tshiab tshaj plaws high density board, qhov chaw ntawm ib tug nplua lead suab thiab nti loj qhov chaw, nws yog ua tau rau reworking kom raug. Tsis tas li ntawd, DH-200 BGA rework chaw nres tsheb tuaj yeem ua tiav tag nrho cov txheej txheem ntawm kev rov ua haujlwm dua, yog tias nws siv nrog Jig. Lawv yog cov cua sov, tshem tawm, ntxuav, luam ntawv. positioning, mounting, re-balling thiab lwm yam thiab nws yog txawm soj ntsuam.

Hauj lwm lawm

1. Khoom nta ntawm 2 Cua sov Zones Kov Screen BGA Rework Tshuab

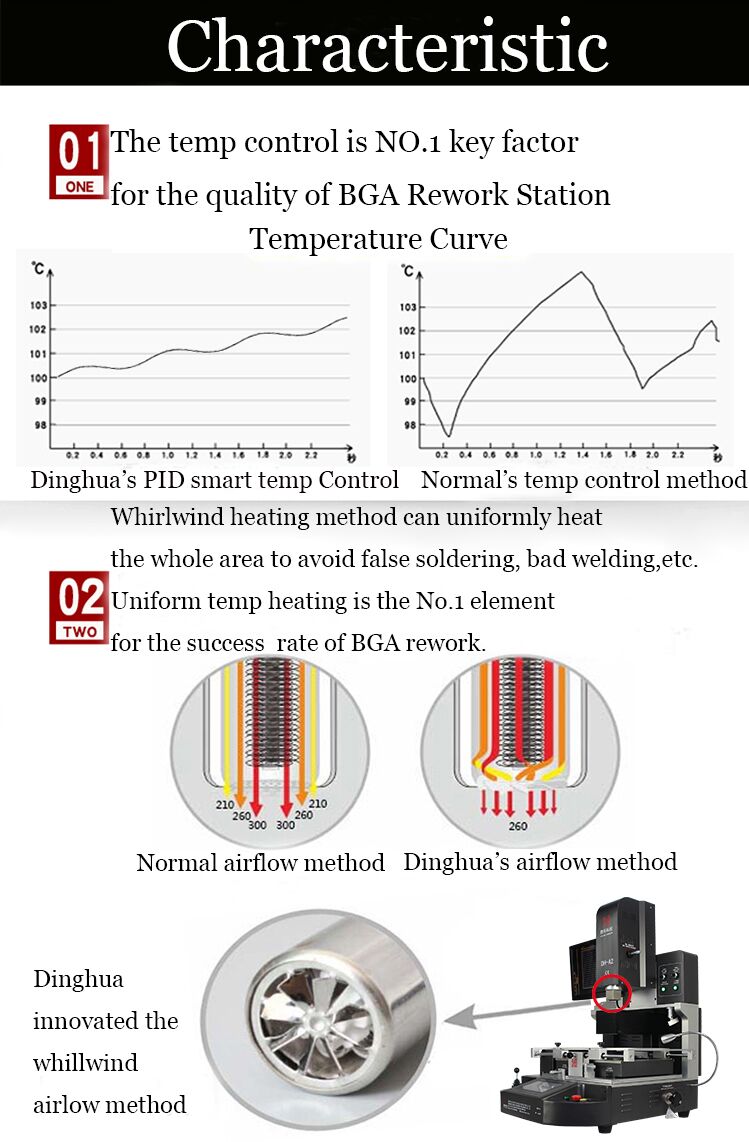

Ua los ntawm cov khoom siv cua sov zoo; desoldering thiab soldering cov txheej txheem ntawm BGA raug tswj kom meej;

Movable cua sov lub taub hau, uas tuaj yeem txav tau yooj yim horizontally, yooj yim rau kev khiav lag luam;

Embedded muaj computer, PLC tswj, real-time profile zaub, muaj peev xwm tso saib teeb profile thiab xyaum-kuaj profile; loj loj screen, yooj yim rau kev khiav lag luam;

Profile txuag tsis muaj kev txwv hauv lub tshuab computer no, tuaj yeem txheeb xyuas ob qhov kev sim-kuaj, tuaj yeem nkag rau lus Askiv thiab Suav;

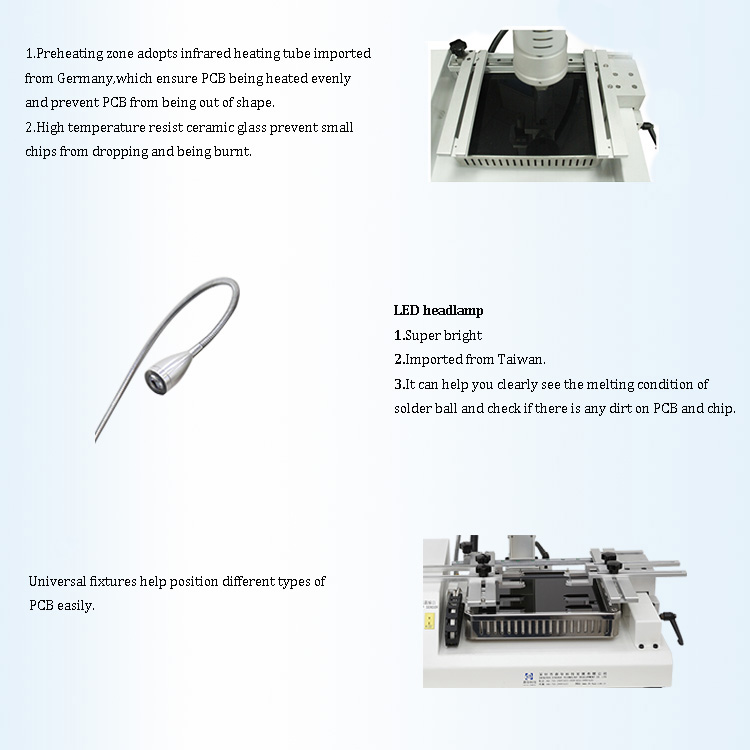

Qhov kub thiab txias ntawm cov cua kub cua sov tuaj yeem tswj tau raws li lawv qhov kub thiab txias. Lub infrared qhov kub thiab txias cua sov cheeb tsam ntawmthaj tsam hauv qab thiab qhov tsim nyog qhov ntsuas kub-tswj ua kom rov ua haujlwm dua

ruaj ntseg thiab txhim khu kev qha.

2. Specification

| Hwj chim | 2300W |

| Lub tshuab cua sov sab saum toj | Cua kub 450W |

| Hauv qab rhaub | Cua kub 1200W, Infrared 1800W |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L540 * W310 * H500 hli |

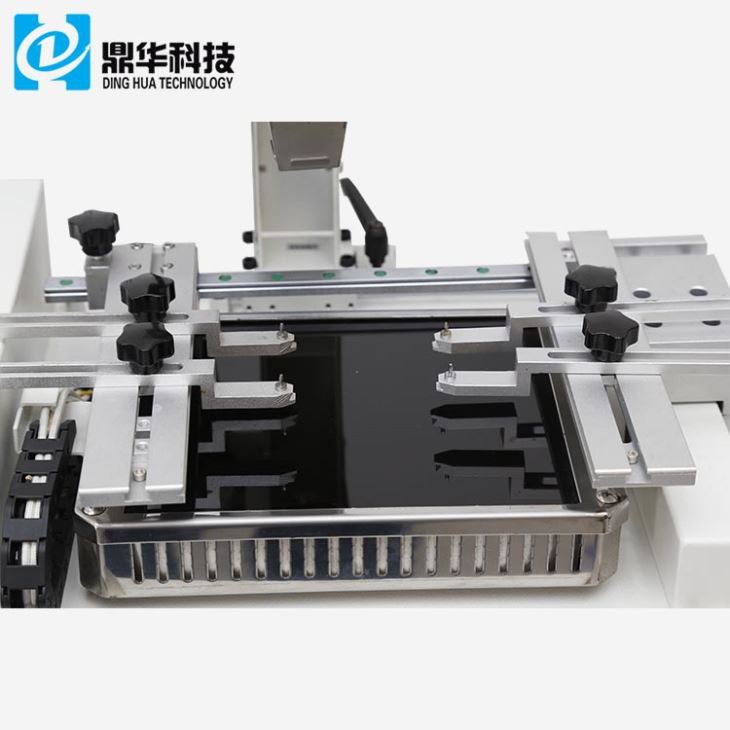

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | K hom thermocouple, kaw voj tswj. ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 170 * 220 hli Min 22 * 22 hli |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab. ± 15mm sab xis / nqa |

| BGAchip | 80 * 80-2 * 2 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (oplional) |

| Net nyhav | 1 6kg |

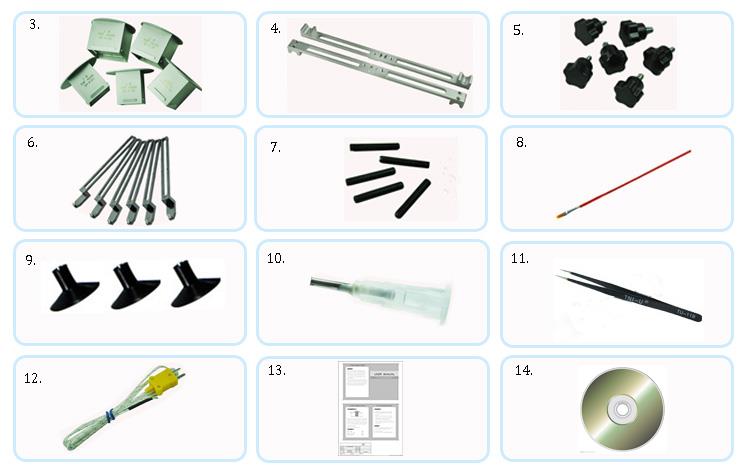

3. Cov ntsiab lus ntawm 2 Cov Cuab Yeej Cuab Yeej Kov Screen BGA Rework Tshuab

1. 2 lub tso cua sov ywj siab ( cua kub & infrared );

2. HD cov zaub;

3. HD touchscreen interface, PLC tswj;

4. Lub taub hau taub hau;

4. Vim li cas thiaj xaiv Peb Cov Cuab Yeej 2 Kov Screen BGA Rework Tshuab?

5. Daim ntawv pov thawj

6.Packing & shipping

7. Muaj Kev Paub Txog 2 Cov Cuab Yeej Cuab Yeej Kov Screen BGA Rework Tshuab

Txhim kho txoj kev rau kev txiav tawm thiab ncoo tso tawm ntawm Mobile Phone Motherboard

- Rau qhov poob taw tes thiab thaum cov hlau lead hauv qab ntawm lub ncoo, siv rab phom cua kub (kub: 240 degree, huab cua ntim: nruab nrab) los tshuab tawm qhov chaw soldered. Ua tib zoo khawb tawm lub hau nrog ib rab riam, tom qab ntawd siv me me ntawm solder paste rau lub qhov taub (pad). Siv rab phom cua kub rau reflow soldering los ua ib lub pob solder, thiab tom qab ntawd ntxuav nrog dej. Yog hais tias lub pob solder tsis poob, nws qhia tau hais tias cov hlau yog zoo soldered thiab yuav siv tau ib txwm.

- Rau disconnection thiab pad tshem tawm, ua ntej siv cov hniav phais kom tshem tawm cov hlau lead uas tawg, tshem tawm yam tsawg 3 hli ntawm cov khoom. Tom qab ntawd, ntxuav lub cheeb tsam nrog flux (Tianna dej). Siv lub tshuab hluav taws xob los siv cov hlau lead. Siv ib feem me me ntawm enameled hlau, uas tau tin-bismuth-tin coated ntawm lub ntsis, thiab muab nws mus rau lub scraped hlau. Tso cov hlau kom zoo, ces siv rab phom cua kub (kub: 280 degree, cua ntws: nruab nrab) rau vuam. Tom qab welding, txiav cov enameled hlau mus rau ib tug ntev ntawm 2 hli. Muab tus pin rau ntawm qhov chaw ntawm lub ncoo, thiab siv lwm tus pin los tso cov hlau enameled nyob ib ncig ntawm tus pin los ua ib lub voj voog ntawm lub ncoo. Siv ib qho me me ntawm cov nplaum nplaum rau lub voj voog, tom qab ntawd siv rab phom cua kub kom rov ua dua lub solder, ua ib lub pob solder.

Yog hais tias cov hlau lead thiab enameled hlau tsis yooj yim rau solder, siv me ntsis solder muab tshuaj txhuam rau qhov sib koom ua ke, ces siv rab phom cua kub (tsis tas kov cov hlau nrog cov hlau soldering). Siv ib rab koob los kho txoj hauj lwm ntawm cov enameled hlau los xyuas kom meej tias nws yog ncaj thiab solder sib koom yog txawm. Lub sijhawm no, lub ncoo tau kho tiav.

3. Tom qab tag nrho cov breakpoints txuas nrog, ntxuav thaj chaw nrog dej. Ceev faj kom tsis txhob cuam tshuam lub ncoo tshiab. Siv cov roj ntsuab me me nyob ib ncig ntawm txoj kab, zam lub ncoo. Tsawg dua yog qhov zoo dua-tsuas yog txaus los tuav cov hlau. Tom qab ua ntawv thov, tso lub rooj sib txoos hauv qab lub teeb liab qab rau ib nrab teev kom rov nruab IC. Txawm hais tias disassembled thiab reassembled ntau zaus, qhov kev sib txuas yuav tsum ruaj ntseg.