Kub Cua Rework BGA Reballing Kit

1. Peb tuaj yeem muab kev cob qhia pub dawb los qhia tias BGA tshuab ua haujlwm li cas.

2. Kev pab txhawb nqa lub neej tuaj yeem muab tau.

3. Kev cob qhia kev cob qhia CD thiab phau ntawv tuaj nrog lub tshuab.

4. Txais tos tuaj xyuas peb lub Hoobkas los kuaj peb lub tshuab

Hauj lwm lawm

Tsis Siv Neeg Kub Kub Rework BGA Reballing Kit yog lub tshuab siv los tshem tawm thiab hloov Ball Grid Array (BGA)

Cheebtsam ntawm cov ntawv luam tawm Circuit Board (PCB). Lub tshuab siv cov cua kub kom yaj cov pob qij txha, tso cai rau BGA tivthaiv

kom raug tshem tawm kom nyab xeeb.

Cov txheej txheem reballing suav nrog khaws cov nti tshiab rau BGA tivthaiv thiab tom qab ntawd rov ua rau lawv nyob rau hauv qhov chaw

ntawm PCB. Qhov no yog ib kauj ruam tseem ceeb hauv kev ua kom ntseeg tau ntawm cov khoom siv tom qab rov ua haujlwm dua.

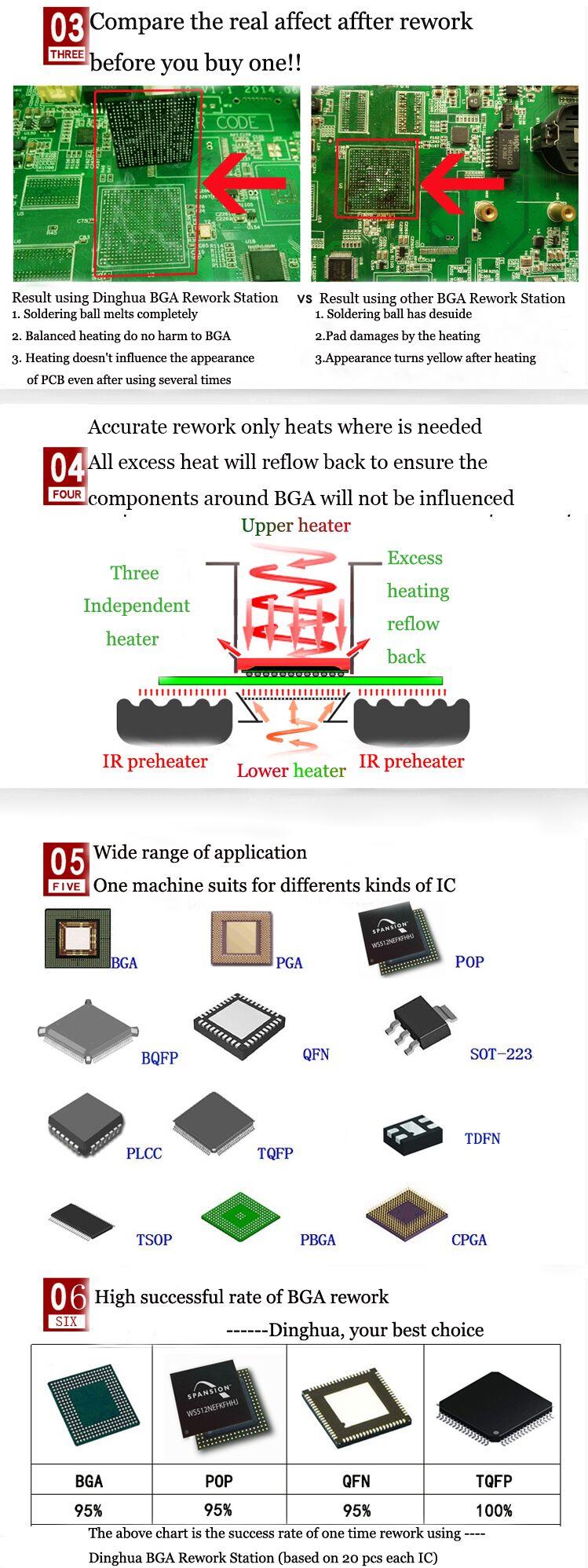

1. Daim Ntawv Thov Tsis Siv Neeg

Ua haujlwm nrog txhua hom motherboards lossis PCBA.

Solder, reball, thiab desoldering ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN,

TSO, PBGA,

CPGA, LED nti.

2. Khoom nta ntawmTsis siv neeg

Cov cua kub tsis siv neeg rework BGA reballing cov khoom siv yog tsim los ua kom muaj txiaj ntsig thiab raug nyob rau hauv cov txheej txheem rework.

Nws yog ib qho yuav tsum muaj cov cuab yeej rau kev kho hluav taws xob thiab tu cov kws tshaj lij ua haujlwm nrog BGA Cheebtsam.

DH-G620 yog tag nrho ib yam li DH-A2, cia li desoldering, tuaj tos, muab rov qab thiab soldering rau ib nti, nrog optical alignment rau mounting, txawm tias koj muaj kev paub los yog tsis, koj tuaj yeem paub nws hauv ib teev.

3.Specification ntawmTsis siv neeg

| Hwj chim | 5300w |

| Lub tshuab cua sov sab saum toj | Cua kub 1200w |

| Hauv qab rhaub | Cua kub 1200W. Infrared 2700w |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | Ktype thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | +2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGA chip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

4.Vim li cas thiaj xaiv pebTsis Siv Neeg Kub Cua Rework BGA Reballing Kit?

5. Daim ntawv pov thawj ntawmTsis siv neeg

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua kom zoo tshaj qhov system, Dinghua

tau dhau ISO, GMP, FCCA, thiab C-TPAT ntawm qhov chaw kuaj ntawv pov thawj.

6. Ntim & Xa khoom ntawmTsis siv neeg

7. Kev xa khoom rauTsis siv neeg

DHL / TNT / FEDEX. Yog tias koj xav tau lwm lub sijhawm shipping, thov qhia rau peb. Peb yuav txhawb koj.

8. Cov nqe lus them nqi

Hloov chaw hauv txhab nyiaj, Western Union, Credit Card.

Thov qhia rau peb yog tias koj xav tau lwm yam kev txhawb nqa.

9. Kev Paub Txog

Ua rau Kev Tshawb Fawb thiab Kev Tiv Thaiv ntawm PCBA Kev Sib Tsoo Kev tawg - Kev tshuaj xyuas qhov ua rau tawg

1. Qhov tawg yog dab tsi?

Kev tawg yog lo lus siv rau delamination lossis foaming ntawm cov ntawv luam tawm Circuit Board (PCBs).

- Delaminationhais txog kev sib cais ntawm cov khaubncaws sab nraud povtseg nyob rau hauv lub substrate, nruab nrab ntawm lub substrate thiab conductive tooj liab ntawv ci, los yog nyob rau hauv lwm yam txheej ntawm PCB.

- Ua npuas ncaujyog ib hom kev delamination uas tshwm sim raws li kev nthuav dav hauv zos thiab kev sib cais ntawm txhua txheej ntawm laminate substrate lossis nruab nrab ntawm cov substrate thiab cov ntawv ci tooj liab lossis cov txheej tiv thaiv. Foaming kuj suav hais tias yog ib daim ntawv ntawm stratification.

2. Kev txheeb xyuas qhov ua rau tawg

Cov neeg siv khoom cov khoom siv hauv kev lag luam-tswj inverters. Cov kev cai tsim qauv qhia cov PCBs nrog CTI (Comparative Tracking Index) qhov tseem ceeb. Qhov no 4- txheej PCB muaj cov cai tshwj xeeb hauv kev tsim khoom thiab kev thov. Vim qhov tshwj xeeb ntawm CTI> 600 cov khoom siv tooj liab-clad, nws tsis tuaj yeem raug nias ncaj qha nrog cov txheej sab hauv. Cov khoom siv no yuav tsum tau nias nrog ntau hom interlayer insulating prepreg cov ntaub ntawv kom tau raws li CTI cov qauv thiab lamination bonding quab yuam.

Vim yog siv ob hom prepreg rwb thaiv tsev cov ntaub ntawv, ob cov ntaub ntawv muaj ntau hom resin. Lub zog sib txuas ntawm fusion interface ntawm ob cov ntaub ntawv rwb thaiv tsev no kuj tsis muaj zog piv rau cov khoom siv rwb thaiv tsev ib leeg siv hauv cov pa 4- txheej boards. Thaum lub PCB nqus dej noo mus rau qee qhov hauv nws lub xeev ntuj, thiab tom qab ntawd dhau los ua yoj yoj los yog phau ntawv ntsaws-hauv soldering, qhov kub nce los ntawm chav tsev kub mus txog 240 degree. Cov dej noo absorbed nyob rau hauv lub rooj tsavxwm yog instantaneously rhuab thiab vaporized, generating internal siab. Yog hais tias lub siab tshaj qhov sib txuas lub zog ntawm cov txheej insulating, delamination los yog foaming tshwm sim.

Feem ntau, kev tawg yog tshwm sim los ntawm qhov tsis txaus ntawm cov khoom siv lossis cov txheej txheem. Cov kev tsis txaus no suav nrog:

- Khoom siv:Copper-clad laminate los yog PCB nws tus kheej.

- Cov txheej txheem:Kev tsim cov txheej txheem ntawm tooj liab-clad laminate thiab PCB, txheej txheem tsim khoom PCB, thiab PCBA (Printed Circuit Board Assembly) txheej txheem.

(1) Moisture Absorption Thaum PCB Manufacturing

Cov khoom siv raw siv hauv PCB tsim muaj kev sib raug zoo rau cov dej thiab yooj yim cuam tshuam los ntawm ya raws. Lub xub ntiag ntawm cov dej hauv PCB, qhov sib txawv ntawm cov dej vapor, thiab kev hloov pauv ntawm cov dej vapor siab nrog qhov kub thiab txias yog thawj qhov ua rau PCB tawg.

Cov dej noo nyob rau hauv PCB feem ntau muaj nyob rau hauv cov resin molecules thiab lub cev tsis xws luag nyob rau hauv lub PCB. Tus nqi nqus dej thiab qhov sib npaug ntawm qhov nqus dej ntawm epoxy resin yog txiav txim siab los ntawm qhov ntim dawb thiab qhov concentration ntawm pawg polar. Qhov loj dua qhov ntim dawb, qhov nrawm dua qhov pib nqus dej sai dua, thiab ntau pawg polar muaj, qhov muaj peev xwm nqus dej ntau dua. Raws li PCB yog reflow soldered los yog yoj soldered, qhov kub nce, ua rau cov dej molecules thiab cov dej hauv hydrogen bonds kom tau txais lub zog txaus rau diffuse hauv cov resin. Cov dej tom qab ntawd kis mus rau sab nraud thiab sib sau ua ke ntawm lub cev tsis xws luag, ua rau muaj qhov nce hauv molar volume. Tsis tas li ntawd, raws li qhov kub ntawm qhov vuam nce, qhov saturated vapor siab ntawm cov dej kuj nce.

Raws li cov ntaub ntawv, raws li qhov kub thiab txias nce, lub saturated vapor siab nce sharply, ncav cuag 400 P / kPa ntawm 250 degree. Yog tias qhov adhesion ntawm cov khaubncaws sab nraud povtseg ntawm cov khoom tsis muaj zog dua li lub siab vapor siab tsim los ntawm cov dej vapor, cov khoom yuav delaminate lossis ua npuas ncauj. Yog li ntawd, kev nqus dej ua ntej soldering yog ib qho tseem ceeb ntawm PCB tawg.

(2) Moisture Absorption Thaum PCB Cia

PCBs nrog CTI> 600 yuav tsum tau kho raws li cov khoom siv ya raws. Lub xub ntiag ntawm cov dej noo hauv PCB cuam tshuam rau nws cov kev sib dhos thiab kev ua haujlwm. Yog tias PCB nrog tus nqi CTI siab yog khaws cia tsis raug lossis raug dej noo, nws yuav nqus dej dhau sijhawm. Nyob rau hauv cov xwm txheej zoo li qub, cov ntsiab lus dej ntawm PCB yuav maj mam nce. Qhov sib txawv ntawm cov dej nqus dej ntawm lub tshuab nqus tsev ntim PCBs thiab cov uas tsis muaj kev cia zoo yog qhia hauv daim duab hauv qab no.

(3) Lub Sij Hawm Ntev Moisture Absorption Thaum PCBA Ntau Lawm

Thaum lub sij hawm tsim cov txheej txheem, lub sij hawm ntev raug rau ya raws los yog lwm yam yuav ua rau kom noo noo nqus nyob rau hauv PCBs nrog CTI > 600. Yog hais tias lub PCB undergoes soldering tom qab absorbing noo noo, muaj kev pheej hmoo ntawm delamination los yog foaming.

(4) Cov txheej txheem soldering tsis zoo hauv PCBA Lead-Free Production

Rau cov hlau tsis muaj hlau lead hauv PCBA ntau lawm, Sn53 / Pb87 solder tau hloov los ntawm SnAg-Cu cov hlau tsis muaj hlau, uas muaj cov ntsiab lus melting ntau dua (217 degree vs. 183 degree). Yog li ntawd, reflow soldering thiab yoj soldering kub tau nce los ntawm 230-235 degree mus rau 250-255 degree, nrog rau lub ncov kub tej zaum yuav ntau dua. Thaum lub sij hawm soldering txheej txheem, yog hais tias lub sij hawm soldering yog ntev heev los yog kub nce sai heev, lub PCB tej zaum yuav raug kev txom nyem los ntawm cov khoom tsis zoo, uas ua rau muaj kev pheej hmoo ntawm delamination los yog foaming.