3 Cua sov Thaj Chaw Kov Screen Bga Soldering Chaw nres tsheb

3 thaj chaw cua sov kov npo bga soldering chaw nres tsheb Qhov no yog lub tshuab ua haujlwm siab kawg, nws suav nrog BGA rework chaw nres tsheb, cov txheej txheem hlau, lub koob yees duab thiab tshuaj ntsuam xyuas, thiab nrov heev rau Xbox, macbook thiab PS3 / 4 thiab lwm yam. kho hauv South America, Middle - East thiab Southeast Asia thiab lwm yam ...

Hauj lwm lawm

3 thaj chaw cua sov kov npo bga soldering chaw nres tsheb

Qhov no yog lub tshuab ua haujlwm siab kawg, nws suav nrog BGA rework chaw nres tsheb, ib txheej ntawm cov hlau nplaum, lub koob yees duab thiab tshuaj ntsuam xyuas,

thiab nrov heev rau Xbox, macbook thiab PS3 / 4 thiab lwm yam. kho hauv South America, Middle - sab hnub tuaj thiab sab hnub tuaj Asia thiab lwm yam.

Cov khoom parameter ntawm 3 cua sov aav kov npo BGA soldering chaw nres tsheb

Tag Nrho Lub Zog | 4900W |

Lub tshuab cua sov sab saum toj | 800W |

Hauv qab rhaub | 2nd 1200W, 3rd IR rhaub 2700W |

Digital Iron zog | 80W |

Hwj chim | AC220V ± 10 ~ 50Hz |

BGA positioning | Laser positioning, tso PCB rau ntawm qhov chaw nrawm. |

Ntxuav tin | Nrog ib tug digital soldering hlau, rau ceev ceev huv si residual tin tom qab desoldering, tiv thaiv PCB thiab bga los ntawm oxidizing |

HD saib screen | 1080P, 15 nti |

Lub koob yees duab | 2 lab pixel |

Teeb pom kev zoo | Ob chav shadowless LED teeb, txhua lub kaum sab xis kho dawb |

Sab saum toj cua sov txav | Txoj cai / sab laug, pem hauv ntej / rov qab, tig ywj siab. |

Hom kev ua haujlwm | HD kov npo, ntse sib tham interface, digital system teeb tsa |

Kub profile cia | 50000 pawg |

Qhov chaw | Qhov chaw ntse, PCB tuaj yeem hloov kho hauv X, Y kev taw qhia nrog "5 ntsiab lus txhawb nqa" + V-groove PCB bracket + universal fixtures. |

Kev tswj qhov kub thiab txias | K sensor, kaw lub voj |

Temp raug | ± 2 degree |

PCB loj | Max420 × 400 mm Min 22 × 22 mm |

BGA chip | 2 x 2 - 80 x 80 mm |

Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

Sab nraud temper sensor | 1pc ua |

Qhov ntev | L640 × W630 × H560 hli |

Net nyhav | 42 KG |

Khoom feature thiab daim ntawv thovntawm 3 thaj chaw cua sov kov npo BGA soldering chaw nres tsheb

· Laser positioning, ceev thiab meej txoj hauj lwm bga thiab pcb.

· Sab nraud digital soldering hlau, pab ntxuav lub bga thiab motherboard kom yooj yim.

· Nrog lub tshuab nqus tsev, khaws bga nti yooj yim.

· Nrog USB 2.0 interface, tuaj yeem txuas nrog lub computer, tswj los ntawm software.

· Kev teeb tsa tiag tiag thiab qhov ntsuas kub ntawm qhov profile tuaj yeem siv los txheeb xyuas thiab kho qhov tsis raug.

· Sab nraud qhov kub thiab txias sensor tso cai rau ntsuas kub thiab ntsuas qhov tseeb ntawm qhov ntsuas kub ntawm lub sijhawm.

· HD kov npo thiab pib lo lus zais rau kev tiv thaiv thiab kev hloov kho, PLC tswj, PID tsis tuaj yeem hloov kho tus kheej,

precision kub module.

· Txais peb thaj chaw cua sov, lub tshuab cua sov sab sauv thiab lub tshuab cua sov qis yog cua kub, lub rhaub hauv qab yog infrared preheat cheeb tsam.

· K hom kaw voj tswj, qhov tseeb qhov kub yuav nyob ntawm ± 2 degree

· Lub tshuab hluav taws xob muaj hluav taws xob muaj hluav taws xob siab, tiv thaiv PCB los ntawm deformation.

· Suab hint system: muaj lub suab ceeb toom 5s-10s ua ntej ua tiav cov cua sov, kom tus neeg teb xov tooj npaj

· Kev ntsuas kev ruaj ntseg: overheat guard thiab thaum muaj xwm ceev nres muaj nuj nqi

Daim ntawv thov:

1. Qhov chaw nres tsheb rov ua haujlwm no tsim nyog rau lub xov tooj ntawm tes motherboard, teeb tsa lub thawv hluav taws xob, lub router Circuit Court board, XBOX 360,

cov khoom siv digital thiab lwm yam

2. Peb qhov kub ntawm cov cua sov ywj siab, sab saum toj cua sov 800W, IR preheating cheeb tsam 2700W, hauv qab rhaub 1200W

3. Qhov kub siab tshaj plaws: 400 degrees

4. Muaj lub khoos phis tawj tau nruab rau hauv lub tshuab rau kev tswj qhov kub thiab txias, qhov kub thiab txias nkhaus, txiav txiav vuam,

preheating, txias, siab precision ntse kub tswj, ua kom kub tswj tau meej heev

5. Movable cua sov lub taub hau, kev ua haujlwm yooj yim

6. Lub zog hluav taws xob hla lub kiv cua txias Circuit Court board

7.Ua hauv lub tshuab nqus tsev nqus cwj mem los khaws BGA nti

8. Infrared cua sov phaj tuaj yeem tswj cov cua sov ntawm tus kheej

9. Universal PCB yas dhos jig tsim, vuam cheeb tsam tsis xav tau ncej

10. Lub hauv qab preheater siv rau preheating PCB board, xyuas kom meej tias PCB phaj tsis deformation, txhawb max loj

420 * 400 hli PCB

11. Haum rau txhua yam kev kho BGA (CCGA, BGA, QFN, CSP, LGA, Micro SMD, MLF ...)

Lead thiab tsis muaj txhuas

Cov khoom lag luam ntawm 3 thaj chaw cua sov kov npo BGA soldering chaw nres tsheb

Saib xyuas lub vijtsam (duab screen), 1080P, 15 nti, peb tuaj yeem soj ntsuam cov txheej txheem ntawm melting thaum soldering.

Lub koob yees duab, 2 lab pixels, siv nrog lub tshuaj ntsuam xyuas rau BGA solder pob soldering soj ntsuam.

Laser positioning, rau PCB thiab nti muab tso rau ntawm qhov chaw sai sai.

Ob chav shadowless teeb, 5W, txawm nyob qhov twg tus engineer sawv, tsis muaj duab ntxoov ntxoo ntawm PCB, uas yuav pab tau.

rau kev soj ntsuam cov txheej txheem soldering.

Cross-flow txias kiv cua, fais fab mov: 24V, ceev: Max 2500 ± 10% RPM, thaum lub tshuab nres lossis khawm ceev,

nws yuav pib ua haujlwm tsis tu ncua.

Kev xa khoom, kev pabcuam shipping ntawm 3 thaj chaw cua sov kov npo bga soldering chaw nres tsheb

1. 1 ~ 3 hnub rau tsawg tshaj li 5 teev, 5 ~ 10 teev rau 3 ~ 5 hnub, ntau tshaj 10 teev, nyob ntawm seb muaj pes tsawg.

2. Muaj kev cob qhia dawb, txhim kho thiab ua haujlwm

3. Rau distributors, ntau warranty lub sij hawm.

Hais txog peb lub Hoobkas

peb lub Hoobkas sab nraud

Peb lub hoobkas

Peb chav exhibition

Rhiav rau BGA rework chaw nres tsheb manufacturing

FAQ ntawm 3 thaj chaw cua sov kov npo bga soldering chaw nres tsheb

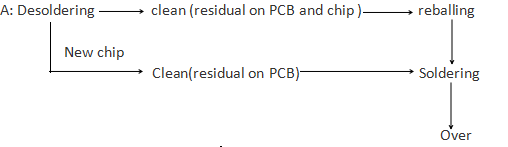

1. Q: Kuv yuav tsum ua li cas rau kev kho cov nti?

2. Q: Kuv puas tuaj yeem ua haujlwm yam tsis muaj kev paub dhau los?

A: Tau kawg, muaj kev qhia CD nrog lub tshuab xa tuaj rau koj, thiab peb

Pab neeg muag khoom-tom qab kev pabcuam tuaj yeem muab kev txhawb nqa zoo tshaj plaws rau koj.

3. Q: Dab tsi yog qhov zoo rau koj cov khoom?

A: Peb muaj peb tus kheej CNC Rhiav uas tuaj yeem tsim tag nrho cov khoom seem rau BGA rework chaw nres tsheb, qhov zoo ntawm

cov khoom tuaj yeem kuaj xyuas los ntawm peb tus neeg kuaj xyuas thaum pib, yog li peb yog thawj lub Hoobkas nrog tus nqi sib tw.

4. Q: Lub tshuab puas yuav tawg thaum xa tawm?

A: Tsis yog, peb yuav ua qhov kev vibration xeem tsawg kawg 24 teev ua ntej xa khoom, tom qab ntawd xyuas lub tshuab dua kom paub tseeb tias txhua yam

yog OK.

Covhais txog kev kho cov lus qhia

Lifted Conductor Kho, Epoxy Seal Method

txheej txheem

1. Ntxuav thaj chaw.

2. Tshem tawm cov kev cuam tshuam uas tiv thaiv lub lifted Circuit Court los ntawm kev sib cuag nrog lub hauv paus board nto.

CEEB TOOM

Ceev faj thaum ntxuav thiab tshem tawm tag nrho cov kev cuam tshuam, tsis txhob ncab lossis ua rau cov neeg nqa nqa nqa.

3. Sib tov cov epoxy.

4. Ua tib zoo siv me me ntawm epoxy nyob rau hauv tag nrho ntev ntawm lub lifted Circuit Court. Lub ntsis ntawm Precision Riam tej zaum yuav

siv los thov cov epoxy. (Saib daim duab 1).

5. Nias lub lifted Circuit Court cia rau hauv epoxy thiab nyob rau hauv kev sib cuag nrog lub hauv paus board khoom.

6. Siv cov epoxy ntxiv rau saum npoo ntawm lub lifted Circuit Court thiab rau txhua sab raws li xav tau.

7. Kho cov epoxy raws li txheej txheem 2.7 Epoxy Mixing thiab tuav.Qee lub Cheebtsam yuav rhiab heev rau kub.

8. Siv cov txheej txheem saum npoo kom phim ua ntej txheej raws li xav tau.