Automated Soldering Rau LED Teeb

Automated Soldering rau LED Teeb. Txawv tsim thiab sib txawv kev daws teeb meem.

Hauj lwm lawm

Automated Soldering rau LED Teeb

1.Models rau Automated Soldering rau LED teeb

A. Ib lub taub hau, ib qho chaw nres tsheb, (R axis)

B. Ib lub taub hau, ob qhov chaw nres tsheb, (R axis)

C. Ob lub taub hau, ib qho chaw nres tsheb, (R axis)

D. Ob lub taub hau, ob qhov chaw nres tsheb, (R axis).

E. Lwm cov qauv tsim muaj. Txais tos tiv tauj peb.

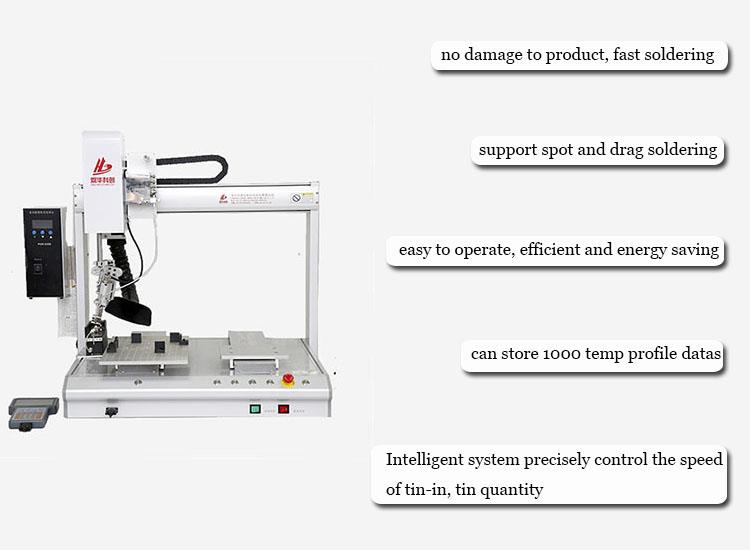

2.Features rau Automated Soldering rau LED teeb

Kev txo qis tib neeg kev siv zog thiab nqi zog ua haujlwm.

Siv-phooj ywg.

Kev ua haujlwm ruaj khov thiab ruaj khov.

3.Application of Automated Soldering rau LED Teeb

Automated soldering tau dhau los ua neeg nyiam hauv kev tsim cov teeb ci LED.

Cov txheej txheem no suav nrog kev siv cov tshuab soldering uas yog programmed los ua cov txheej txheem soldering

kev khiav hauj lwm cia li. Yog li ntawd, lub tshuab no muaj ntau yam txiaj ntsig thaum nws los txog rau

kev tsim cov teeb ci LED.

Ua ntej, automated soldering xyuas kom meej tias cov txheej txheem soldering zoo ib yam thiab raug. Cov tshuab

yog programmed ua hauj lwm nyob rau hauv ib tug sib xws ceev ceev, kub, thiab siab, uas tshem tawm txoj kev pheej hmoo ntawm

tib neeg yuam kev. Qhov no ua kom txhua qhov kev sib txuas ruaj ntseg, thiab cov khoom tiav yog cov khoom zoo.

Secondly, automated soldering ho txo lub sij hawm tsim ntawm LED teeb. Cov txheej txheem no ntau heev

sai dua li phau ntawv soldering, raws li cov cav tov tuaj yeem ua ntau yam kev sib txuas ib txhij. Qhov no txhais tau tias

tias cov tuam ntxhab tuaj yeem tsim cov teeb ci LED ntawm tus nqi nrawm dua, uas txo cov nqi tsim khoom thiab txhim kho

efficiency.

Thib peb, automated soldering tshem tawm txoj kev pheej hmoo ntawm kev raug mob rau cov neeg ua haujlwm. Los ntawm txhais tes soldering yog ib qho kev phom sij

uas ua rau cov neeg ua haujlwm raug kub hnyiab thiab cov pa phem. Automated soldering tshem tawm cov kev pheej hmoo no, raws li cov

cov cav tov ua txhua yam kev ua haujlwm yam tsis tas yuav tsum muaj kev cuam tshuam rau tib neeg.

Nyob rau hauv xaus, daim ntawv thov ntawm automated soldering nyob rau hauv zus tau tej cov LED teeb muaj ntau yam kev pab.

Lub tshuab ua kom zoo ib yam thiab raug soldering, txo cov sij hawm tsim khoom thiab cov nqi, thiab tshem tawm cov

pheej hmoo raug mob rau cov neeg ua haujlwm. Raws li qhov kev thov rau cov teeb ci LED txuas ntxiv mus, automated soldering tau dhau los ua ib qho

indispensable cuab tam rau manufacturers tab tom nrhiav kom nyob twj ywm kev sib tw thiab tsim cov khoom zoo zoo.

6. Daim ntawv pov thawj ntawmAutomated Soldering rau LED Teeb

![]()

Zoo siab txais tos cov neeg ua lag luam los ntawm thoob plaws lub ntiaj teb. Txais tos tiv tauj peb!

7. Muaj kev paub txog

Los ntawm cov ntsiab lus ntawm solder, nws tuaj yeem pom tau tias "wetting" yog tus protagonist hauv cov txheej txheem vuam. Qhov hu ua vuam

yog siv cov kua "solder" ntub dej ntawm lub substrate kom ua tiav cov nyhuv sib koom ua ke. Qhov tshwm sim no zoo li dej ntog rau ntawm ib qho

khoom nto. Qhov txawv yog tias cov vuam yuav solidify rau hauv ib qho kev sib koom ua ke raws li qhov kub thiab txias. Thaum lub solder ntub rau

lub substrate, theoretically, cov hlau bonds nrog cov hlau los ua ib qho kev sib txuas mus tas li. Txawm li cas los xij, nyob rau hauv cov xwm txheej tiag tiag, lub

substrate yog eroded los ntawm huab cua thiab ib puag ncig ib puag ncig los tsim ib txheej oxide zaj duab xis los thaiv cov "solder", kom nws muaj peev xwm

tsis ua tiav cov nyhuv wetting zoo dua. Qhov tshwm sim yog tias dej yog nchuav rau ntawm lub phaj uas muaj roj, dej tuaj yeem tsuas yog con-

centrated nyob rau hauv qee qhov chaw, thiab tsis tuaj yeem sib npaug thiab sib npaug ntawm cov phaj. Yog hais tias oxide zaj duab xis nyob rau saum npoo ntawm lub

substrate tsis raug tshem tawm, txawm tias nws tsuas yog coated nrog "solder", lub zog sib txuas tsis muaj zog heev.

1. Txawv vuam thiab gluing

Thaum ob cov ntaub ntawv sib txuas ua ke los ntawm cov kua nplaum, qhov chaw ntawm ob cov ntaub ntawv sib txuas rau ib leeg vim cov kua nplaum

muab ib tug mechanical bond ntawm lawv. Vim tias cov kua nplaum tsis yooj yim kho ntawm ob qho tib si, lub ntsej muag ci tsis zoo

raws li qhov ntxhib los yog etched nto. Gluing yog qhov tshwm sim saum npoo uas tuaj yeem rub tawm ntawm qhov qub thaum cov kua nplaum

yog ntub. Vuam yog tsim los ntawm ib tug hlau chemical bond ntawm lub solder thiab cov hlau. Cov molecules ntawm solder nkag mus

rau hauv cov qauv molecular ntawm cov hlau saum npoo ntawm lub substrate los tsim kom muaj zog, tag nrho cov qauv hlau. Thaum lub solder melts, nws

Nws yog tsis yooj yim sua kom so nws tawm ntawm cov hlau nto vim nws tau los ua ib feem ntawm lub hauv paus hlau.

2, ntub dej thiab tsis ntub

Ib daim ntawm cov ntawv hlau greased yog immersed nyob rau hauv dej thiab tsis muaj wetting. Nyob rau hauv tas li ntawd, cov dej yuav tsim ib tug spherical dej droplet

uas yuav co tawm, yog li cov dej tsis ntub los yog lo rau cov ntawv hlau. Yog tias cov ntawv hlau raug ntxuav hauv cov kuab tshuaj kub, ua tib zoo

qhuav, thiab tom qab ntawd muab tso rau hauv dej, cov dej yuav tag nrho diffuse mus rau saum npoo ntawm cov ntawv hlau los ua ib txheej txheej zaj duab xis nyias.

Nws yuav tsis poob, piv txwv li nws twb ntub cov ntawv hlau.

3, huv

Thaum cov ntawv hlau yog huv heev, cov dej yuav ntub dej. Yog li ntawd, thaum lub "solder nto" thiab "hlau nto" kuj heev

huv si, lub solder yuav ntub cov hlau nto, uas yog huv si ntau dua li dej. Cov ntawv hlau muaj ntau dua vim tias yuav tsum muaj ib

nruj kev twb kev txuas ntawm lub solder thiab hlau, txwv tsis pub ib tug nyias oxide txheej yog tsim nyob rau hauv nruab nrab ntawm lawv. Hmoov tsis, yuav luag tag nrho cov hlau

oxidize tam sim ntawd thaum raug huab cua, thiab qhov no tsis tshua muaj oxide txheej yuav cuam tshuam nrog cov ntub dej ntawm cov hlau ntawm cov hlau.

Lus Cim: "Solder" txhais tau tias 60/40 lossis 63/37 tin-lead alloy; "substrate" yog hais txog cov hlau yuav tsum tau welded, xws li PCB los yog ib feem ko taw.

4, capillary kev ua haujlwm

Yog hais tias ob lub hlau huv si raug coj los ua ke, muab tso rau hauv lub molten solder, lub solder yuav ntub ob lub hlau nto thiab nce mus rau qhov sib txawv ntawm qhov chaw nyob ib sab, uas yog capillary nkaus. Yog hais tias cov hlau nto tsis huv, yuav tsis ntub dej thiab capillary ua, thiab cov solder yuav tsis sau cov ntsiab lus no. Thaum cov ntawv luam tawm Circuit Board ntawm lub plated los ntawm lub qhov dhau los ntawm lub yoj soldering rauv, qhov quab yuam ntawm capillary ua tiav lub qhov los ntawm lub qhov, thiab lub npe hu ua "soldering daim kab xev" yog tsim rau ntawm lub rooj tsavxwm luam tawm, thiab lub siab ntawm lub tin yoj tsis yog soldered kiag li. Nias lub qhov.