BGA IC Chip Kho Tshuab

Dinghua DH-A2 automated BGA IC Chip Kho Tshuab nrog kev ua tiav zoo ntawm kev kho. Lub neej kev txhawb nqa tuaj yeem muab.

Hauj lwm lawm

Qauv: DH-A2

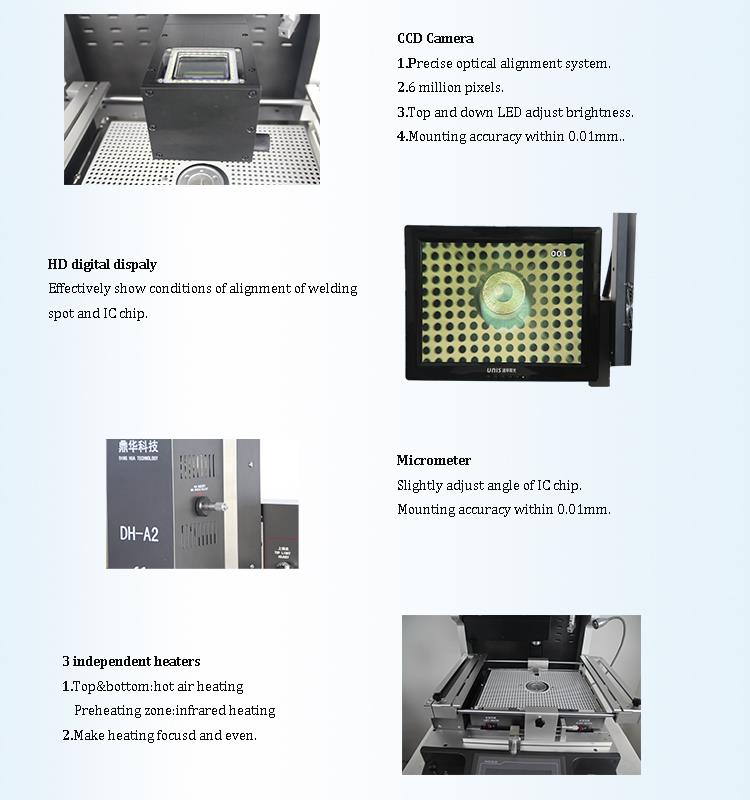

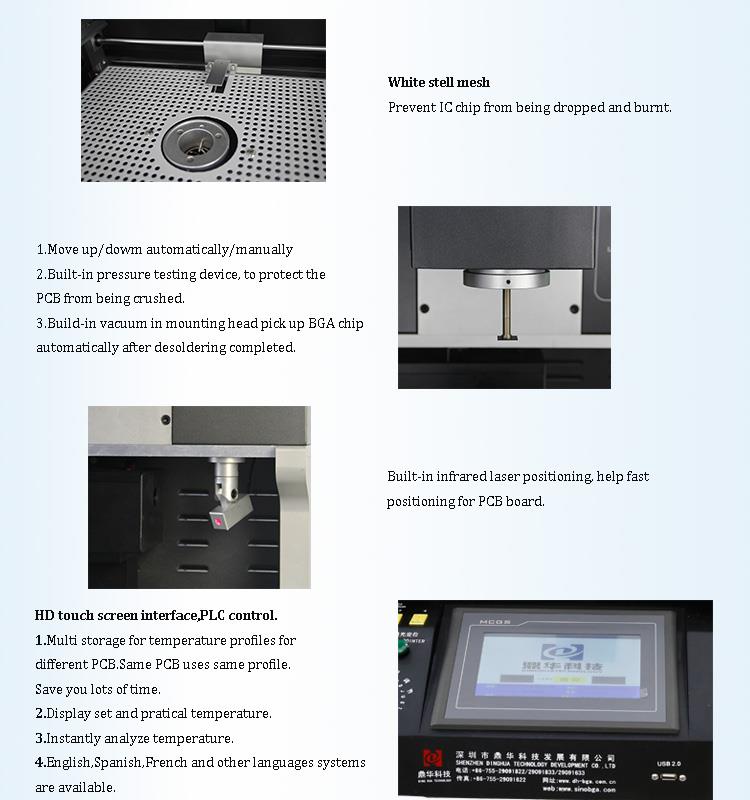

1.Application Of Automatic

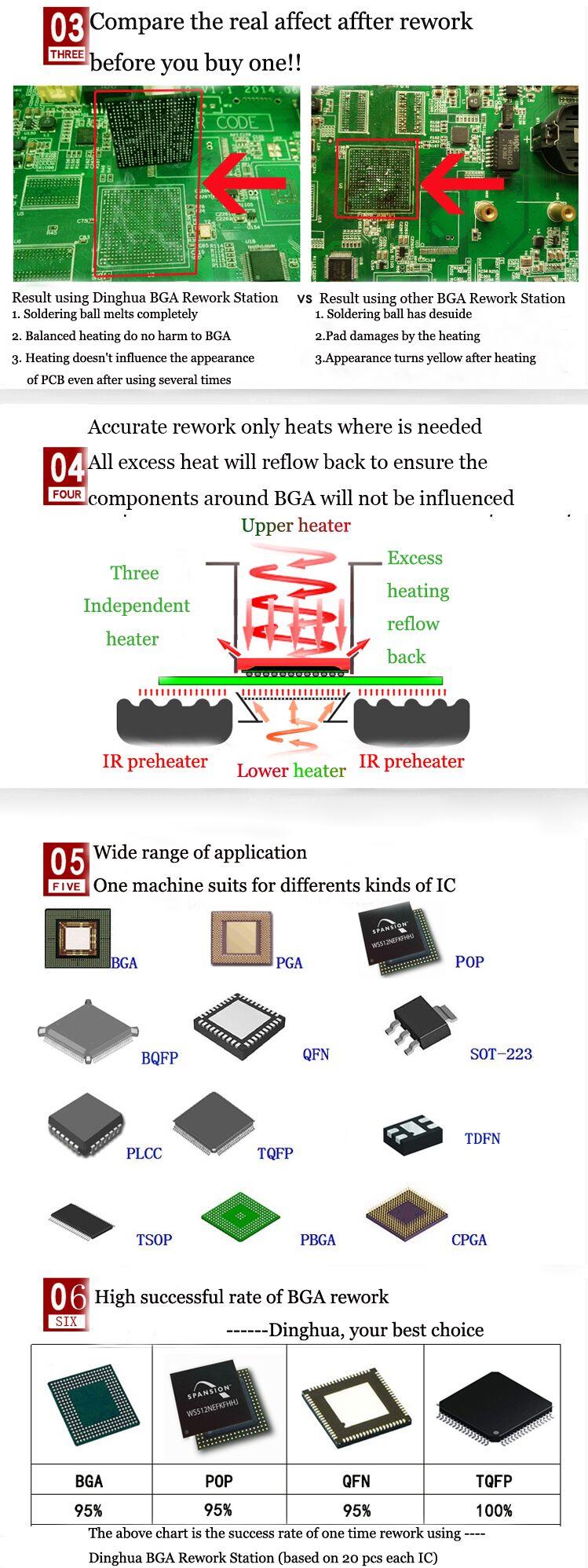

Solder, reball, desoldering ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED nti.

2.Advantage ntawm Kub Cua Tsis Siv Neeg BGA IC Chip Kho Tshuab

3.Technical cov ntaub ntawv ntawm laser positioning tsis siv neeg

4.Cov qauv ntawm Infrared CCD lub koob yees duab

5.Vim li cas cua kub reflow BGA IC Chip Kho Tshuab yog koj xaiv zoo tshaj?

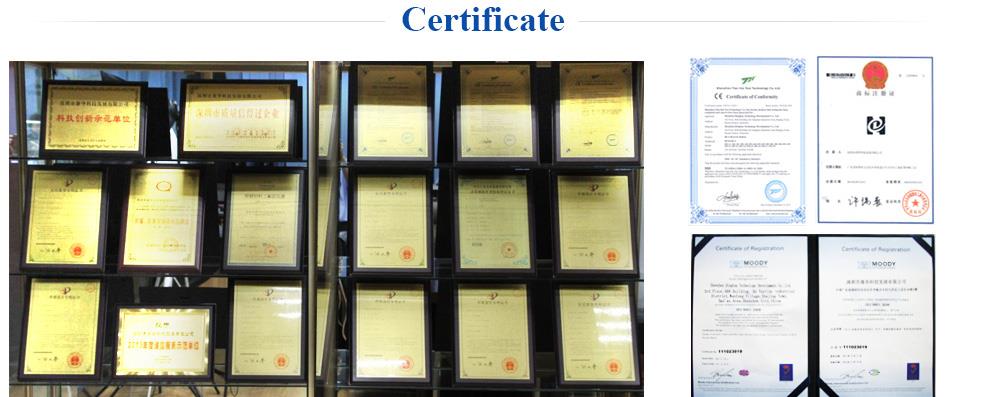

6.Certificate of Optical Alignment Automatic

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua kom zoo dua qhov system zoo,

Dinghua tau dhau ISO, GMP, FCCA, C-TPAT ntawm qhov chaw kuaj ntawv pov thawj.

7.Packing & shipping ntawm CCD lub koob yees duab

8.Shipment rauSplit Vision Automatic

DHL / TNT / FEDEX. Yog tias koj xav tau lwm lub sijhawm shipping, thov qhia rau peb. Peb yuav txhawb koj.

9. Kev Paub Txog Tsis Siv Neeg Infrared BGA IC Chip Kho Tshuab

Niaj hnub no, tsis siv neeg solder paste printing presses yog nce siv nyob rau hauv industrial ntau lawm. Txawm li cas los xij, thaum lub tshuab luam ntawv tsis siv neeg muab tshuaj txhuam siv rau lub sijhawm ntev, cov khoom siv yuav tsis muaj teeb meem xws li kev laus thiab xeb. Yog li ntawd, yuav tsum tau saib xyuas tshwj xeeb rau kev tswj xyuas cov khoom siv tsis siv neeg solder paste luam ntawv. Ntawm no, peb qhia txog txoj kev kho kom raug:

Ua ntej, xyuas thiab ntxuav cov hlau mesh

Txheeb xyuas qhov chaw ntawm stencil template:

- (1) Txheeb xyuas lub nplhaib xauv lub tog raj kheej ntawm cov qauv stencil ruaj khov rau txhua qhov xoob.

- (2) Xyuas seb lub stopper ntawm lub stencil ruaj yog xoob.

Template ntxuav:

- (1) Residual solder paste rau thiab ib ncig ntawm cov qauv tuaj yeem cuam tshuam rau adhesion, deposition, thickness, thiab tag nrho cov solder zoo. Kev tu tus qauv tsis tu ncua yog qhov tseem ceeb rau kev luam ntawv kom raug. Tom qab ib co PCB boards tau luam tawm (nyob ntawm kev siv, feem ntau txhua txhua 1 mus rau 3 luam ntawm 0.3 hli zoo-pitch PCB boards), ntxuav hauv qab ntawm lub template. Yog tias tsis tau ntxuav tam sim ntawd, cov qauv ntawm qhov apertures tuaj yeem yooj yim los ntawm kev thaiv cov tshuaj nplaum, cuam tshuam rau qhov zoo ntawm kev luam ntawv.

- (2) Muaj peb txoj hauv kev rau kev ntxuav tsis siv neeg: ntxuav qhuav, ntxuav ntub, thiab ntxuav lub tshuab nqus tsev. Siv cov ntawv ntxuav yob rau cov cuab yeej thiab cov cawv cawv ua cov tshuaj ntxuav.

- (3) Raws li cov kua theem hloov nyob rau hauv lub tank cawv (nyob rau hauv lub rear bracket ntawm lub tshuab), cov kua theem ntawm cov tshuaj ntxuav yog saib xyuas thaum lub sij hawm tsis siv neeg tu. Yog hais tias cov tshuaj ntxuav dej poob qis dua qhov hloov, lub kaw lus yuav tawm lub tswb thiab qhia qhov ua rau. Nyob rau lub sijhawm no, lub tank cawv yuav tsum tau ntim nrog cov cawv cawv.

Cov kauj ruam:

- (1) Tua lub tshuab cua hloov ntawm sab laug sab ntawm lub tshuab.

- (2) Qhib lub hau rov qab ntawm lub tshuab thiab lub hau ntawm lub tank cawv.

- (3) Ncuav cov tshuaj ntxuav (kev lag luam cawv) rau hauv lub tank.

- (4) Tom qab sau lub tank cawv, hloov lub hau thiab kaw lub hau tom qab.

- (5) Tig lub tshuab cua rov qab.

Thib ob, ntu luam ntawv:

- Tshawb xyuas seb puas muaj cov khoom siv tshuaj pleev xim rau ntawm lub tshuab luam ntawv.

- Siv ib daim ntaub huv si nrog cawv me ntsis los ntxuav qhov chaw.

- Tshawb xyuas cov khoom seem ntawm cov khoom siv hluav taws xob ntawm qhov sib kis thiab qhov chaw / clamping Cheebtsam.

- Tshem lub hau npog ib ncig ntawm lub rooj zaum ua haujlwm thiab ntxuav cov ntawv qhia thiab cov kab ntawv qhia siv cov ntaub paj rwb huv.

- Lubricate daim ntawv qhia cov ntsia hlau thiab cov kab ntawv qhia nrog NSK rail lubricant thiab tshwj xeeb ntsia hlau lubricant.

- Ntxuav cov sensors nrog ib daim ntaub paj rwb dampened nrog me ntsis cawv.

- Kho cov X thiab Y txoj kev taw qhia lub sijhawm siv yog xav tau.

- Hloov lub hau.

Thib peb, scraper system:

- Qhib lub tshuab lub hau ntej.

- Txav cov nqaj hlau mus rau qhov tsim nyog, loosen cov ntsia hlau ntawm lub taub hau scraper, thiab tshem tawm cov phaj siab.

- Loosen cov screws ntawm lub scraper hniav thiab tshem tawm cov hniav.

- Ntxuav cov hniav thiab scraper nrog ib daim ntaub paj rwb dipped hauv cawv.

- Reinstall cov hniav xovxwm phaj thiab scraper hniav mus rau lub taub hau scraper.

- Yog hais tias lub scraper hniav yog hnav, nws yuav tsum tau hloov.

Yam khoom:

- Cua kub reflow soldering tshuab

- Motherboard kho tshuab

- SMD micro Cheebtsam daws

- SMT rework soldering tshuab

- IC hloov tshuab

- BGA nti reballing tshuab

- BGA rov

- IC nti tshem tawm tshuab

- BGA rework tshuab

- Cua kub solder tshuab

- SMD rework chaw nres tsheb