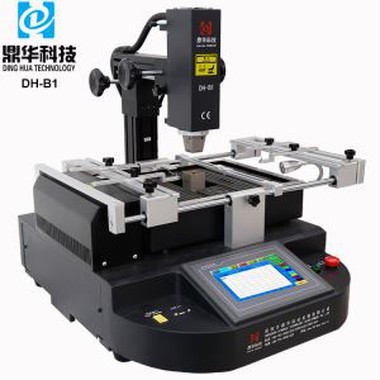

3 Cov Cuab Yeej Cuab Yeej Kov Screen BGA Rework Tshuab

1. Kov npo thiab kho qhov muag kho qhov system.

2. Kev ua tiav siab ntawm kev kho cov chips.

3. Tsis ua puas rau IC nti thiab PCB.

4. Yooj yim heev rau kev khiav lag luam. Tau kawm siv hauv 10 feeb.

5. tuaj yeem khaws 100 txhiab tus kub profiles. Yog tias PCB thiab nti yog tib yam, koj tsis tas yuav teeb lwm qhov kub thiab txias. Txuag sij hawm!

Hauj lwm lawm

1. Daim ntawv thov

Haum rau PCB ntawm cov khoom siv hluav taws xob sib txawv.

Lub motherboard ntawm lub computer, smartphone (iPhone, Huawei, Samsung), laptop, MacBook logic board, digital koob yees duab, cua txias, TV thiab lwm yam khoom siv hluav taws xob los ntawm kev kho mob kev lag luam, kev lag luam kev sib txuas lus, kev lag luam tsheb, thiab lwm yam.

Haum rau ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED nti.

2. Khoom nta

• Nws pib desoldering, mounting thiab soldering.

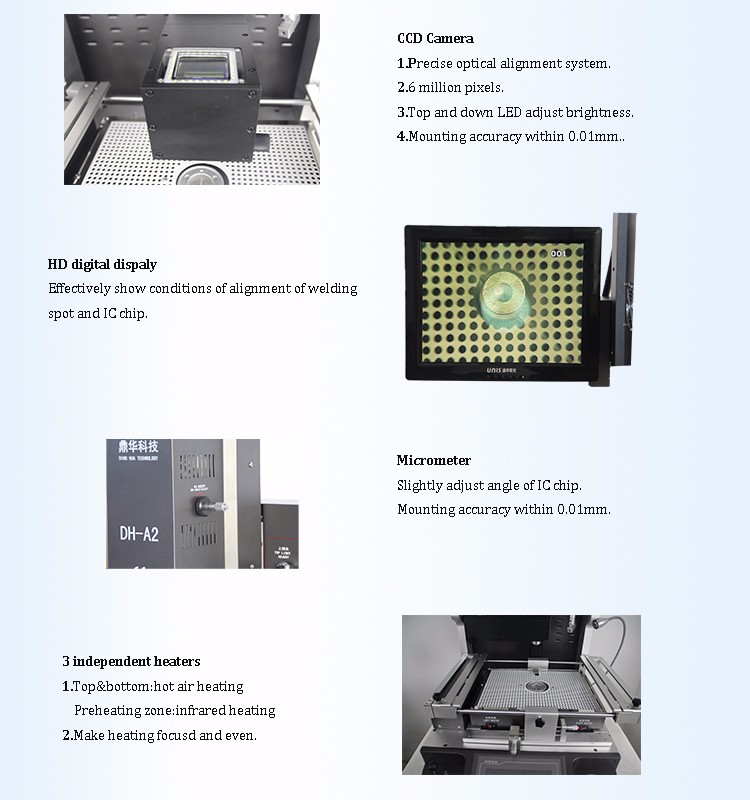

• Lub kaw lus kho qhov muag pom tseeb

Panasonic CCD lub koob yees duab lens ua tau zoo ua kom qhov tseeb ntawm kev sib dhos thiab kev ua tiav ntawm kev kho. Duab dispayed ntawm lub monitor screen.

• Sab saum toj kub airflow yog adjustable, kom tau raws li qhov kev thov ntawm tej daim

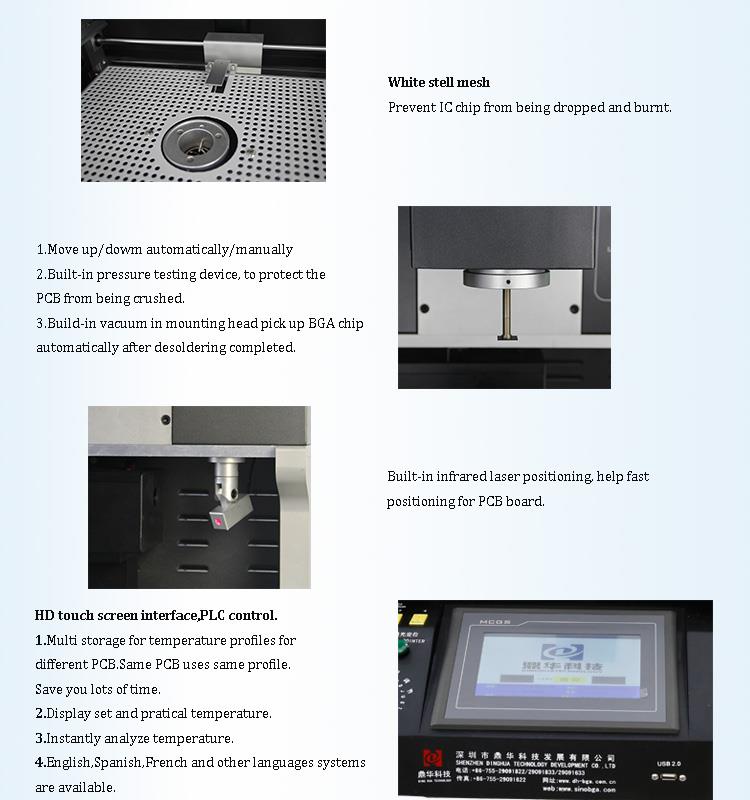

• Ua-nyob rau hauv infrared laser positioning, pab ceev positioning rau PCB.

• Sab saum toj cua sov lub taub hau thiab mounting taub hau 2 nyob rau hauv 1 tsim.

• Mounting lub taub hau nrog built-in siab ntsuas ntsuas, los tiv thaiv PCB los ntawm crushed.

3. Specification

| Hwj chim | 5300w |

| Lub tshuab cua sov sab saum toj | Cua kub 1200w |

| Hauv qab rhaub | Cua kub 1200W. Infrared 2700w |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | Ktype thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGA chip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

4. Paub meej

1.CCD lub koob yees duab (txoj kev kho qhov muag pom tseeb);

2.HD cov zaub;

3. Micrometer (kho lub kaum sab xis ntawm lub nti);

4.3 cov cua sov ywj siab ( cua kub & infrared );

5. Laser qhov chaw;

6. HD kov npo interface, PLC tswj;

7. Coj lub taub hau;

8.Joystick tswj.

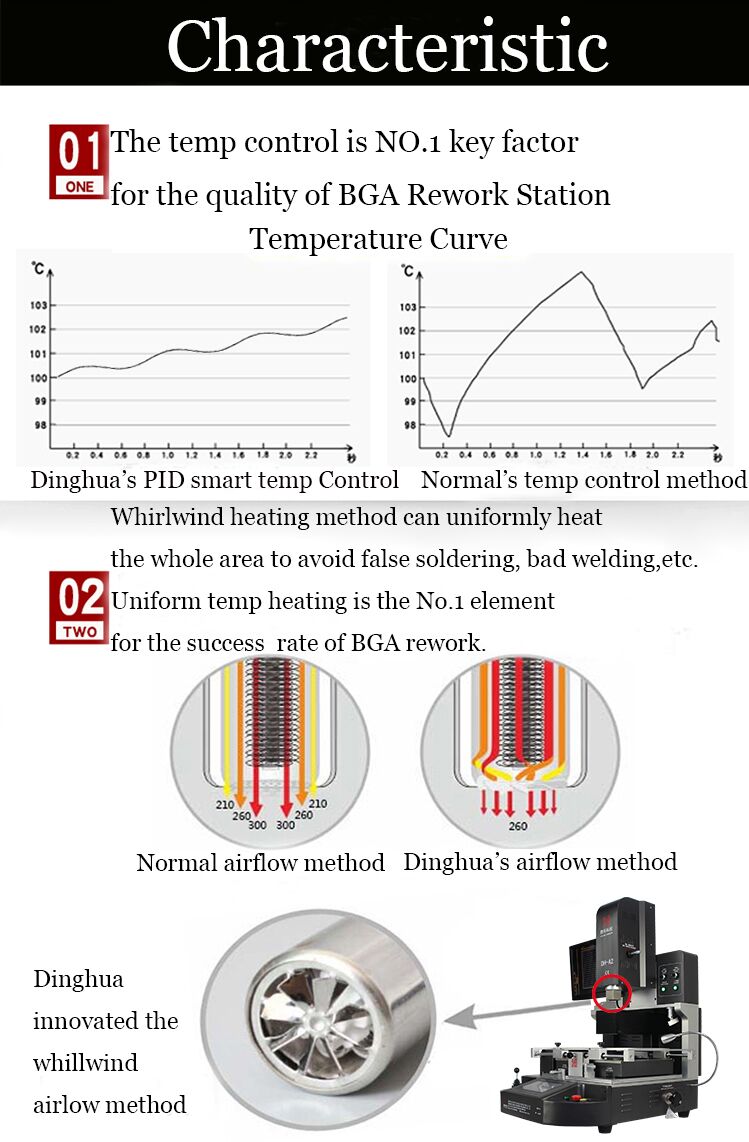

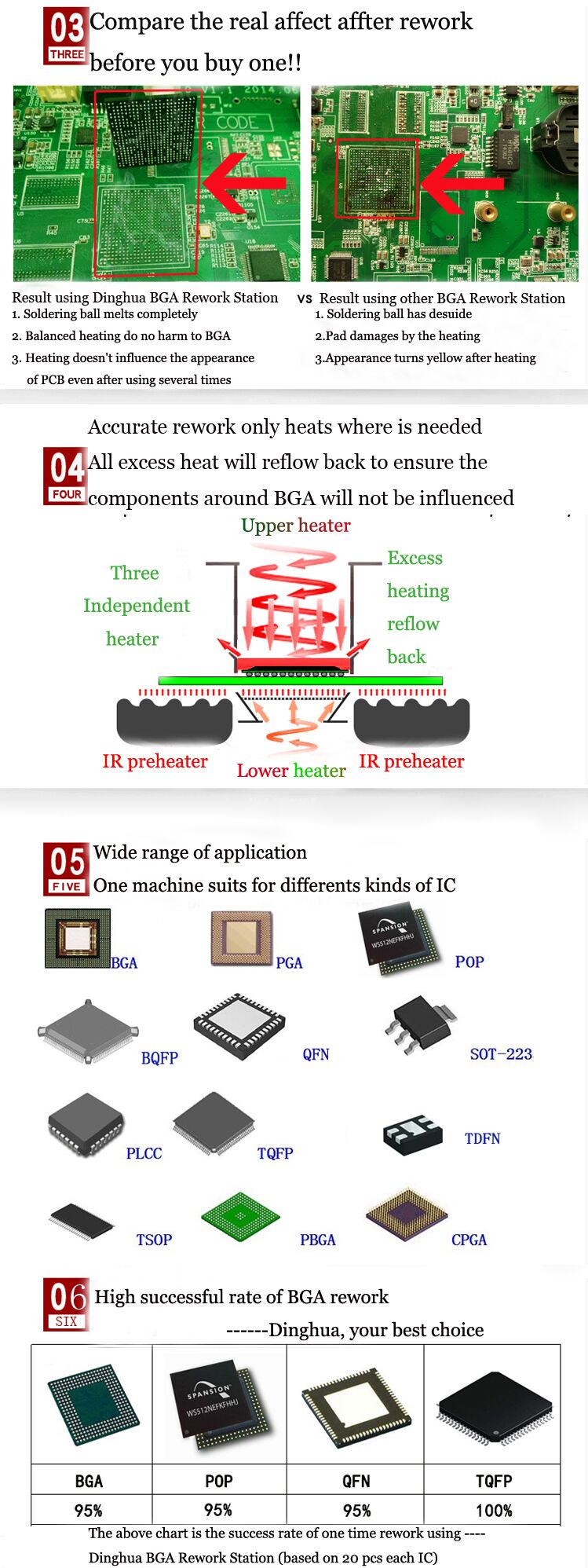

5.Vim li cas thiaj xaiv Peb 3 thaj chaw cua sov kov npo bga rework tshuab?

6. Daim ntawv pov thawj

Txhawm rau muab cov khoom lag luam zoo, SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD yog thawj zaug dhau UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua tiav cov txheej txheem zoo, Dinghua tau dhau ISO, GMP, FCCA, C-TPAT ntawm qhov chaw tshawb xyuas ntawv pov thawj.

7. Ntim & Xa khoom

8. Hu rau peb

Email: john@dh-kc.com

WhatsApp/Wechat/Mob:+86 157 6811 4827

9.FAQ

• Hauv BGA rework tshuab, dab tsi yog qhov tseem ceeb ntawm kev ua tau zoo ntawm kev kho PCB thiab chips?

A: Cov xim kho qhov muag nrog kev ua haujlwm ntawm kev pom kev sib cais, ob xim sib cais, zoom hauv / tawm thiab micro-kho, nruab nrog cov cuab yeej tshawb pom aberration, nrog autofocus thiab software ua haujlwm

•Yuav ua li cas koj lub tshuab BGA rework lav precision kev sib raug zoo ntawm cov pob solder ntawm chips thiab soldering sib koom ntawm PCB?

A: Xim kho qhov muag pom kev, nrog phau ntawv x-, Y-axis txav, nrog faib lub teeb ob-xim, zoom hauv / tawm thiab ua haujlwm zoo, suav nrog cov xim sib txawv daws teeb meem. Lub vijtsam zaub qhia kom meej meej qhia txog kev sib raug zoo ntawm cov pob solder ntawm cov chips thiab soldering sib koom ua ke ntawm PCB.

•Lub hauv paus ntsiab lus ntawm cov cua kub thiab cua sov infrared ntawm koj lub tshuab BGA rework yog dab tsi?

A: Muaj peb lub tshuab hluav taws xob ywj pheej. Sab saum toj Kub Cua + Hauv qab Cua Kub + Infrared preheating platform. Cov cua kub muaj qhov zoo ntawm kev ua kom sov thiab txias. Qhov kub thiab txias yog yooj yim heev los tswj Cov hauv qab ntawm infrared los tiv thaiv PCB deformation (Cov laj thawj deformation dav dav: Qhov kub sib txawv ntawm qhov chaw ntawm PCB thiab lub hom phiaj BGA nti.) Cov qauv ntawm lub tshuab no kuj yooj yim los tswj thiab qhov kub thiab txias yog yooj yim tswj.