BGA Kho Kub Cua Reflow Chaw Nres Tsheb

1. BGA Kho Kub Cua Reflow Chaw Nres Tsheb

2. Tsis muaj kev puas tsuaj rau BGA, nti, PCBA, lossis motherboards thaum kho

3. Cov qauv nrov tshaj plaws hauv khw

4. Cov neeg siv-phooj ywg

Hauj lwm lawm

Tsis Siv Neeg BGA Kho Kub Cua Reflow Chaw Nres Tsheb nrog 3 lub tshuab cua sov thiab kho qhov muag kho qhov muag

Ib qho tsis siv neeg BGA kho cov cua kub reflow chaw nres tsheb nrog peb lub rhaub thiab kho qhov muag kho qhov muag yog ib qho khoom siv tshwj xeeb uas siv los kho Ball Grid Array (BGA) chips ntawm cov ntawv luam tawm Circuit Board (PCBs). Hom chaw nres tsheb no tau siv dav los ntawm cov tuam txhab tsim khoom siv hluav taws xob thiab kho vaj tse.

1. Daim ntawv thov ntawm Tsis Siv Neeg BGA Kho Kub Cua Reflow Chaw Nres Tsheb

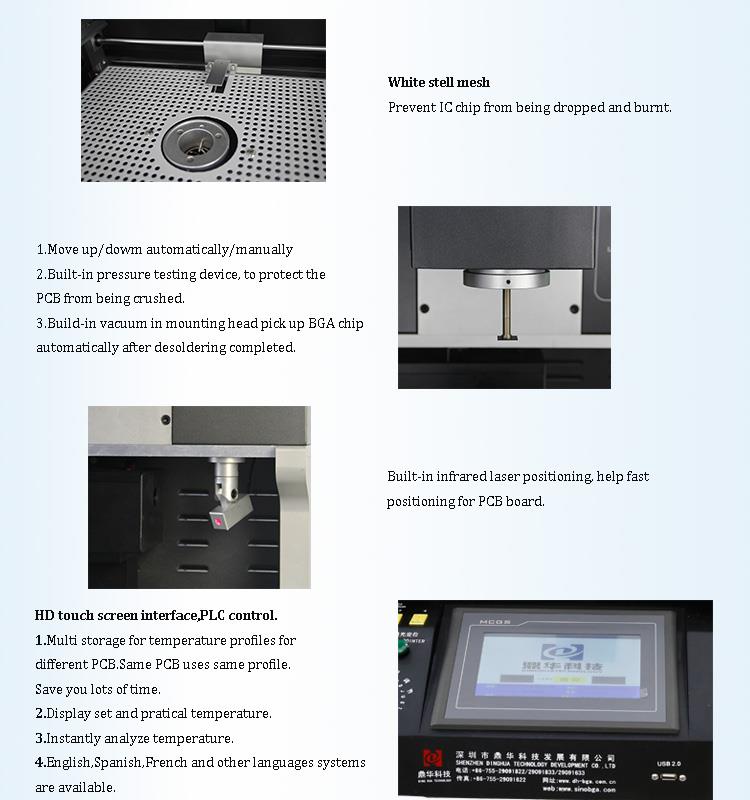

Qhov chaw nres tsheb muaj peev xwm ntawm soldering, reballing, thiab desoldering ntau hom chips, xws li:

- BGA, PGA, POP, BQFP, QFN

- SOT223, PLCC, TQFP, TDFN, TSOP

- PBGA, CPGA, thiab LED chips

2. Khoom nta ntawm qhov tsis siv neeg BGA Kho Kub Cua Reflow Chaw nres tsheb

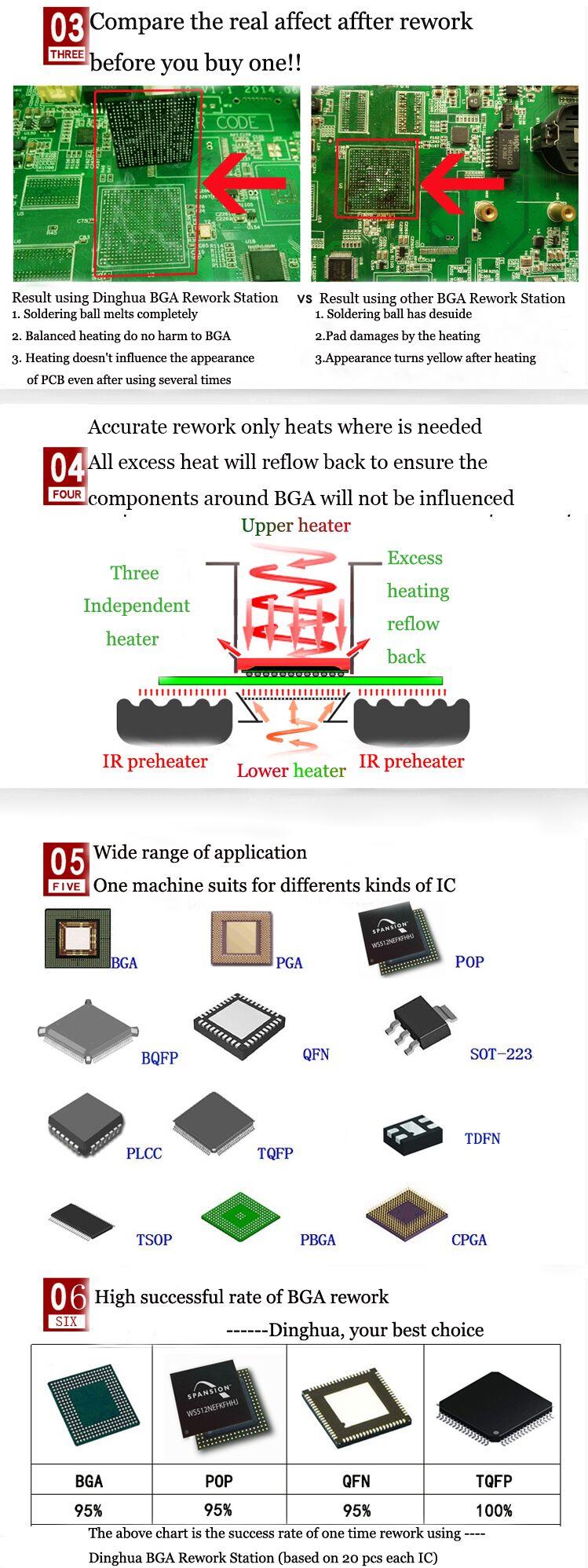

Qhov chaw nres tsheb no yog tsim los kho BGA chips yam tsis muaj kev puas tsuaj rau cov khoom nyob ib puag ncig ntawm PCB. Nws suav nrog peb tus kheej tswj cov cua sov ib puag ncig kom ntseeg tau meej qhov ntsuas kub thaum lub sijhawm rov ua haujlwm.

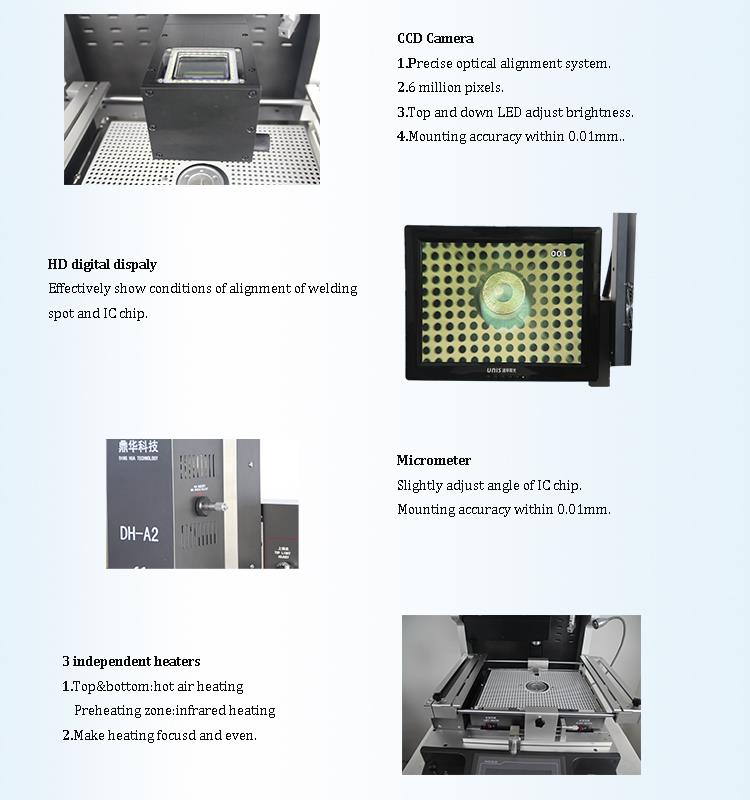

Cov yam ntxwv tseem ceeb:

- Durable thiab ntseeg tau:Kev ua haujlwm ruaj khov nrog lub neej ntev.

- Ntau yam:Muaj peev xwm kho ntau yam motherboards nrog kev ua tiav siab.

- Kub Precision:nruj me ntsis tswj cov cua sov thiab cua txias kom tiv thaiv kev puas tsuaj.

- Optical Alignment System:Xyuas kom qhov tseeb mounting tsis pub dhau 0.01 hli.

- Tus neeg siv-phooj ywg:Yooj yim rau kev khiav lag luam, tsuas yog 30 feeb los kawm. Tsis tas yuav muaj kev txawj tshwj xeeb.

3. Specification ntawm Tsis Siv Neeg BGA Kho Kub Cua Reflow Chaw Nres Tsheb

| Hwj chim | 5300w |

| Lub tshuab cua sov sab saum toj | Cua kub 1200w |

| Hauv qab rhaub | Cua kub 1200W. Infrared 2700w |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | Ktype thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGA chip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

4.Cov ntsiab lus ntawm Tsis Siv Neeg BGA Kho Kub Cua Reflow Chaw Nres Tsheb

5.Vim li cas thiaj xaiv Peb Tsis Siv Neeg BGA Kho Chaw Nres Tsheb Kub Cua Reflow?

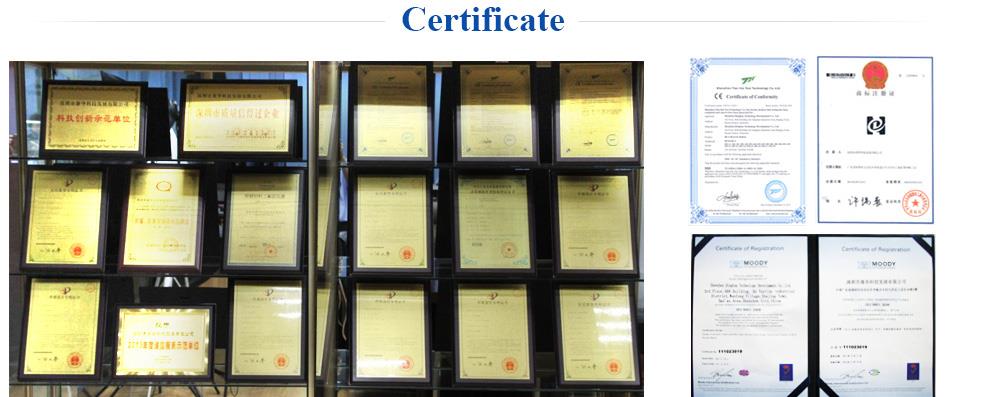

6.Certificate of Automatic BGA Repair Hot Air Reflow Station

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua tiav cov txheej txheem zoo, Dinghua tau dhau ISO, GMP, FCCA, C-TPAT ntawm qhov chaw tshawb xyuas ntawv pov thawj.

7.Packing & Shipment ntawm Tsis Siv Neeg BGA Kho Kub Cua Reflow Chaw Nres Tsheb

8.Shipment rauTsis Siv Neeg BGA Kho Kub Cua Reflow Chaw Nres Tsheb

DHL / TNT / FEDEX. Yog tias koj xav tau lwm lub sijhawm shipping, thov qhia rau peb. Peb yuav txhawb koj.

9. Cov nqe lus them nqi

Hloov chaw hauv txhab nyiaj, Western Union, Credit Card.

Thov qhia rau peb yog tias koj xav tau lwm yam kev txhawb nqa.

11. Muaj Kev Paub Txog

SMT (Surface Mount Technology) cov txheej txheem tsim khoom muaj cov kauj ruam hauv qab no: kev tshuaj ntsuam luam ntawv (lossis xa tawm), kev tso kawm, kho, rov ua dua, ntxuav, tshuaj xyuas, thiab rov ua haujlwm dua.

1, Silk Screen Printing:

Lub hom phiaj yog los luam cov tshuaj nplaum los yog nplaum rau hauv cov ntaub qhwv ntawm PCB hauv kev npaj rau cov khoom siv soldering. Cov cuab yeej siv yog lub tshuab luam ntawv tshuaj ntsuam (screen printer), feem ntau nyob rau thaum pib ntawm SMT ntau lawm kab.

2, Kev faib tawm:

Cov kauj ruam no siv cov nplaum rau cov haujlwm tshwj xeeb ntawm PCB kom ruaj ntseg cov khoom hauv qhov chaw. Cov cuab yeej siv yog lub dispenser, uas tej zaum yuav muab tso rau ntawm qhov pib ntawm SMT kab lossis tom qab cov khoom siv tshuaj ntsuam xyuas.

3, Qhov chaw:

Cov kauj ruam no suav nrog qhov tseeb tso cov khoom siv saum npoo av mus rau lawv txoj haujlwm xaiv ntawm PCB. Cov cuab yeej siv yog lub tshuab tso chaw, nyob tom qab lub tshuab luam ntawv tshuaj ntsuam hauv SMT cov kab ntau lawm.

4, Kev kho mob:

Lub hom phiaj yog kom yaj cov nplaum kom cov khoom nto-mounted tau ruaj khov rau PCB. Cov cuab yeej siv yog lub qhov cub curing, nyob tom qab lub tshuab tso rau hauv SMT kab.

5, Reflow Soldering:

Cov kauj ruam no melts lub solder muab tshuaj txhuam kom ruaj ntseg cov khoom nto-mounted rau PCB. Cov cuab yeej siv yog lub qhov cub reflow, nyob tom qab lub tshuab tso rau hauv SMT kab.

6, Ntxuav:

Lub hom phiaj yog tshem tawm cov teeb meem seem, xws li flux, los ntawm PCB sib dhos. Cov cuab yeej siv yog lub tshuab ntxuav, uas tuaj yeem yog qhov chaw nres tsheb ruaj khov lossis ib qho system inline.

7, Kev tshuaj xyuas:

Cov kauj ruam no ntsuas qhov sib dhos thiab soldering zoo ntawm PCB. Cov khoom siv tshuaj ntsuam xyuas muaj xws li tsom iav tsom iav, tsom iav tsom iav, cov ntsuas hluav taws xob hauv Circuit Court (ICT), kev sojntsuam ya davhlau, kev tshuaj xyuas tsis siv neeg kho qhov muag (AOI), cov tshuab kuaj X-ray, thiab cov ntsuas kev ua haujlwm. Cov chaw soj ntsuam tau teeb tsa ntawm cov ntsiab lus tsim nyog raws li cov kab ntau lawm raws li xav tau.

8, Rework:

Lub hom phiaj yog los kho PCBs uas raug txheeb xyuas thaum kuaj. Cov cuab yeej siv rau rework muaj xws li soldering hlau, rework chaw nres tsheb, thiab lwm yam khoom siv zoo sib xws. Rework chaw nres tsheb tuaj yeem muab tso rau txhua qhov chaw hauv cov kab ntau lawm raws li qhov yuav tsum tau ua.