DH-5860 BGA Rework Chaw nres tsheb

1.Model: DH-58602.Kov npo tswj: Yes3.3 ywj siab cua sov zones: Yes4.Micro Cua Flow Kho: Rau saum taub hau

Hauj lwm lawm

DH-5860 BGA Rework Chaw nres tsheb

1.Application of DH-5860 BGA Rework Station

Motherboard ntawm lub computer, ntse xov tooj, laptop, MacBook logic board, digital koob yees duab, cua txias, TV thiab

lwm yam khoom siv hluav taws xob los ntawm kev kho mob kev lag luam, kev sib txuas lus kev lag luam, kev lag luam tsheb, thiab lwm yam.

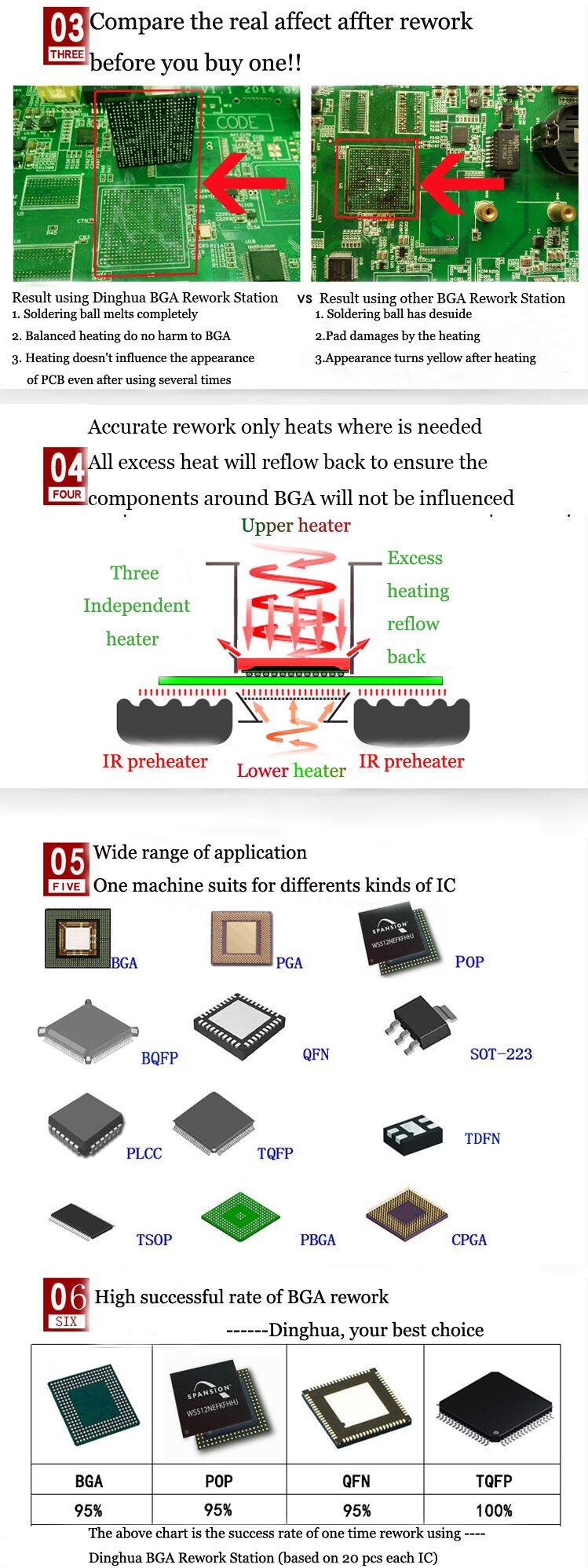

Haum rau ntau hom chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA,

LED nti.

2.Product Nta ntawm DH-5860 BGA Rework Chaw nres tsheb

• Kev ua tau zoo ntawm kev kho cov chips.

(1) Precise kub tswj.

(2) Lub hom phiaj nti tuaj yeem raug soldered lossis desoldered thaum tsis muaj lwm yam khoom ntawm PCB puas.

los yog fake welding.

(3) Peb qhov chaw cua sov ywj siab nce qhov kub thiab txias maj mam.

(4) Tsis muaj kev puas tsuaj rau nti thiab PCB.

• Kev ua haujlwm yooj yim

Humanized tsim ua rau lub tshuab ua haujlwm yooj yim. Feem ntau tus neeg ua haujlwm tuaj yeem kawm siv nws hauv 10 feeb. Tsis muaj

Kev paub tshwj xeeb lossis kev txawj ntse yog xav tau, uas yog lub sijhawm- thiab txuag hluav taws xob rau koj lub tuam txhab ..

3.Specification ntawm DH-5860 BGA Rework Chaw nres tsheb

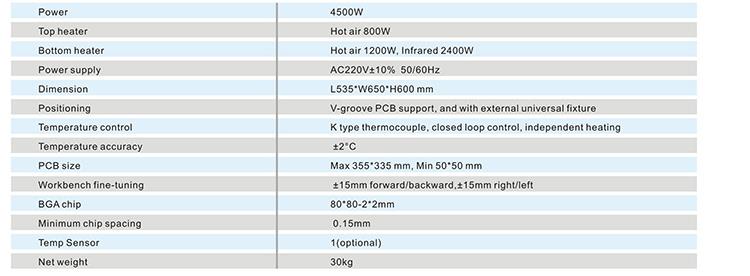

4.Details of DH-5860 BGA Rework Station

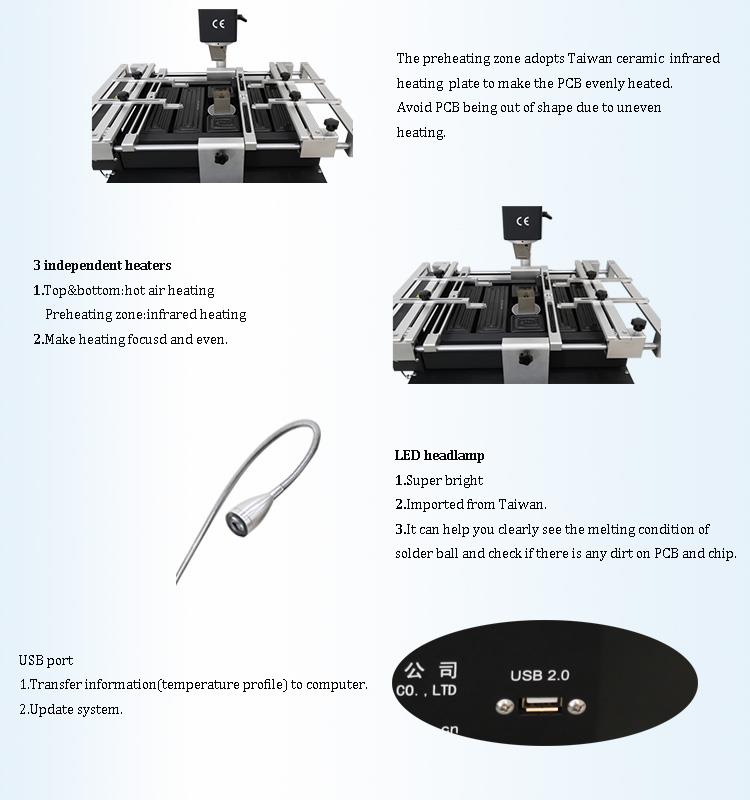

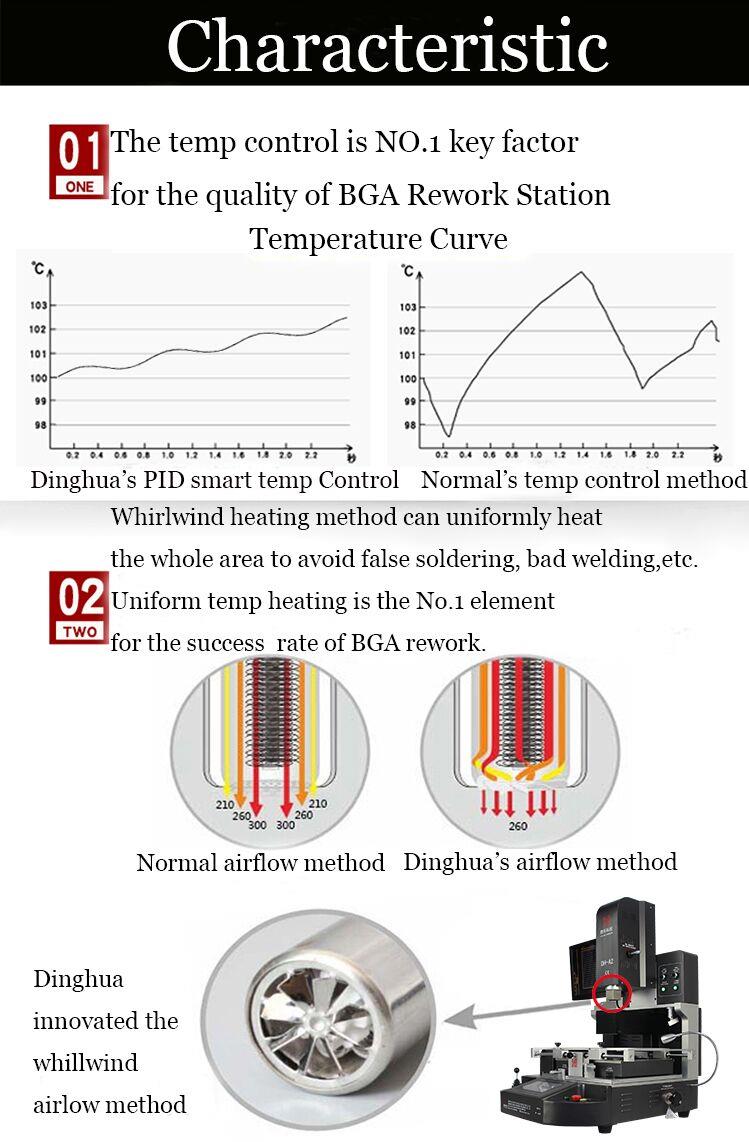

5.Vim li cas thiaj xaiv peb DH-5860 BGA Rework Chaw nres tsheb?

6.Certificate of DH-5860 BGA Rework Chaw nres tsheb

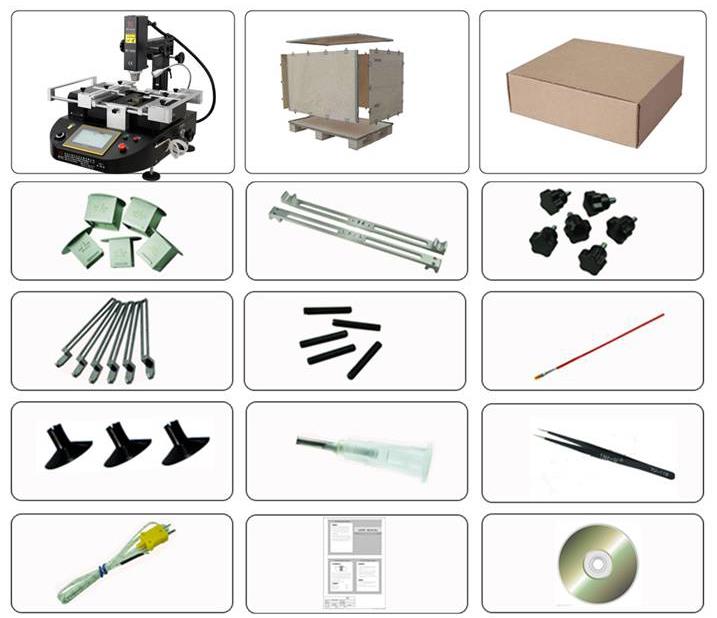

7.Packing & Shipment ntawm DH-5860 BGA Rework Chaw nres tsheb

8.Related knowledges of DH-5860 BGA Rework Chaw nres tsheb

Preheating - qhov chaw ntawm kev ua haujlwm tiav

Nws yog qhov tseeb tias kev ua haujlwm ntev ntawm PCBs ntawm qhov kub thiab txias (315-426 degree C) ua rau muaj teeb meem ntau yam. Thermal puas, xws li

ncoo thiab lead warpage, substrate delamination, dawb me ntsis los yog blistering, discoloration. Phaj warping thiab hlawv feem ntau ua rau tus neeg soj ntsuam

ua tib zoo mloog. Txawm li cas los xij, qhov tseeb vim tias nws tsis "kub tawm lub rooj tsavxwm" tsis txhais hais tias "lub rooj tsavxwm tsis puas." Qhov "invisible"

kev puas tsuaj rau PCB los ntawm qhov kub thiab txias yog qhov hnyav dua li cov teeb meem tau teev tseg saum toj no. Tau ntau xyoo lawm, ntau qhov kev sim siab tau rov ua dua

pom tau tias PCBs thiab lawv cov khoom tuaj yeem "dhau" tom qab rov ua haujlwm thiab sim, nrog tus nqi lwj ntau dua li cov PCB boards. Cov

"invisible" teeb meem ntawm xws li internal warping ntawm substrate thiab attenuation ntawm nws Circuit Court Cheebtsam los ntawm qhov sib txawv expansion coefficients

ntawm cov khoom sib txawv. Pom tseeb, cov teeb meem no tsis tshwm sim rau tus kheej, txawm tias tsis paub tseeb thaum pib ntawm kev ntsuas hluav taws xob, tab sis tseem nyob hauv PCB.

kev sib dhos.

Txawm hais tias nws zoo nkaus li zoo tom qab "kho", nws zoo li ib lo lus hais tias: "Kev ua haujlwm tau zoo, tab sis tus neeg mob yog hmoov tsis tuag." Qhov laj thawj ntawm qhov loj

thermal stress yog tias thaum lub PCB sib dhos ntawm qhov kub thiab txias (21 degree) mam li nco dheev hu cov hlau soldering nrog lub tshav kub ntawm txog 370 degree C,

cov cuab yeej soldering lossis lub taub hau cua kub rau cov cua sov hauv zos, qhov sib txawv ntawm qhov kub thiab txias ntawm lub rooj tsavxwm Circuit Court thiab nws cov khoom yog hais txog 349 degree C. Hloov, tsim

phenomenon ntawm "popcorn".

Qhov tshwm sim ntawm "pob kws" yog hais txog qhov tshwm sim uas cov dej noo uas muaj nyob rau hauv ib qho kev sib koom ua ke lossis SMD hauv lub cuab yeej yog cua sov sai thaum lub sijhawm

kho cov txheej txheem, ua rau cov dej noo o thiab micro-burst los yog tawg. Yog li ntawd, kev lag luam semiconductor thiab circuit board manufacturing kev lag luam xav tau

cov neeg ua haujlwm tsim khoom kom txo qis lub sijhawm sov so thiab sai sai rau qhov kub thiab txias ua ntej reflow. Qhov tseeb, PCB tivthaiv reflow txheej txheem twb

suav nrog ib theem preheating ua ntej reflow. Txawm hais tias PCB sib dhos cog siv yoj soldering, infrared vapor theem lossis convection reflow soldering,

txhua txoj kev yog feem ntau preheated lossis kho cua sov, thiab qhov kub thiab txias feem ntau yog 140-160 degree . Ntau yam teeb meem hauv kev rov ua dua tshiab tuaj yeem daws tau nrog lub sijhawm luv luv

preheating PCB ua ntej reflow soldering. Qhov no tau ua tiav hauv cov txheej txheem reflow rau ntau xyoo. Yog li ntawd, cov txiaj ntsig ntawm preheating PCB sib dhos ua ntej

rau reflow yog manifold.

Txij li thaum lub preheating ntawm lub phaj txo cov reflow kub, yoj soldering, IR / vapor theem vuam, thiab convection reflow soldering tag nrho yuav ua tau ntawm

txog 260 degree.

Cov txiaj ntsig ntawm preheating yog multifaceted thiab dav

Ua ntej, preheating los yog "cov rwb thaiv tsev" cov khoom ua ntej pib reflow pab qhib lub flux, tshem tawm cov oxides thiab cov yeeb yaj kiab saum npoo ntawm cov hlau los ua.

welded, raws li zoo raws li volatiles los ntawm flux nws tus kheej. Raws li, xws li kev ntxuav ntawm lub tshuab nqus dej ua ntej ua ntej reflow txhim kho cov nyhuv ntub dej. Preheating ua kom sov

tag nrho los ua ke rau qhov kub thiab txias hauv qab lub melting point ntawm solder thiab reflow. Qhov no zoo heev txo qhov kev pheej hmoo ntawm thermal shock rau lub substrate thiab nws cov khoom.

Tsis tas li ntawd, cua sov ceev yuav ua rau kom qhov kub thiab txias gradient nyob rau hauv lub rooj sib txoos thiab tsim ib tug thermal shock. Qhov loj kub gradients tsim nyob rau hauv lub

Kev sib dhos yuav tsim cov thermo-mechanical kev ntxhov siab uas ua rau cov khoom siv thermal nthuav dav no qis, ua rau tawg thiab puas. SMT nti resistors thiab

capacitors tshwj xeeb tshaj yog raug rau thermal shock.

Tsis tas li ntawd, yog tias tag nrho lub rooj sib txoos yog preheated, qhov kub ntawm reflow tuaj yeem txo thiab lub sij hawm rov qab tuaj yeem ua kom luv. Yog tias tsis muaj preheating, tib txoj kev yog

txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txiav Txoj kev twg los tsis haum, yuav tsum zam.

Kev kho kom txo qis ua rau cov boards txhim khu kev qha

Raws li kev siv rau qhov ntsuas kub, txoj kev sib txawv ntawm qhov sib txawv, thiab qhov kub ntawm qhov sib txawv. Piv txwv li, feem ntau ntawm yoj soldering

kub yog li ntawm 240-260 degree C, lub vapor theem soldering kub yog hais txog 215 degree C, thiab lub reflow soldering kub yog hais txog 230 degree C. Yog hais lus,

qhov rework kub tsis siab tshaj qhov reflow kub. Txawm hais tias qhov kub thiab txias nyob ze, nws yeej tsis tuaj yeem ncav cuag qhov kub thiab txias. Qhov no yog vim

tag nrho cov txheej txheem rework tsuas yog yuav tsum tau cua sov ntawm ib cheeb tsam, thiab reflow yuav tsum tau cua sov ntawm tag nrho cov PCB los ua ke, seb nws yog yoj soldering IR los yog vapor theem.

reflow soldering.

Lwm qhov tseem ceeb txwv qhov ntsuas kub ntawm reflow hauv rework yog qhov yuav tsum tau ntawm kev lag luam tus qauv uas qhov kub ntawm cov khoom nyob ib ncig ntawm lub rework point.

yuav tsum tsis txhob siab tshaj 170 degree. Yog li ntawd, qhov kub thiab txias thaum lub sij hawm rework yuav tsum tau sib xws nrog qhov loj ntawm PCB los ua ke nws tus kheej thiab qhov loj ntawm cov khoom.

yuav tsum tau reflowed. Txij li nws yog qhov tseem ceeb ntawm kev ua haujlwm ib nrab ntawm PCB, cov txheej txheem rov ua haujlwm txwv qhov ntsuas kub ntawm PCB. Cov cua sov ntau ntawm lub localized

rework yog siab tshaj qhov kub ntawm cov txheej txheem ntau lawm kom offset lub tshav kub nqus ntawm tag nrho cov board los ua ke.

Hauv qhov kev nkag siab no, tseem tsis muaj laj thawj txaus los qhia tias qhov ntsuas kub ua haujlwm ntawm tag nrho lub rooj tsavxwm tsis tuaj yeem siab dua qhov ntsuas kub rov qab hauv kev tsim khoom.

txheej txheem, yog li mus txog lub hom phiaj kub pom zoo los ntawm cov chaw tsim khoom semiconductor.

Xa kev nug

Koj Tseem Yuav Zoo Li

-

Dinghua DH-A2E Optical mus ua haujlwm BGA Rework Sta...

-

Gaming Laptop Infrared BGA Rework Chaw nres tsheb DH...

-

Txawb xov tooj BGA Kub Cua Rework Chaw nres tsheb DH...

-

Kov npo iPhone BGA cov chaw nres tsheb khiav ceev

-

2 Cov Cuab Yeej Cuab Yeej Kov Screen BGA Rework Chaw...

-

Kho qhov muag Xbox360 BGA Chaw nres tsheb khiav ceev