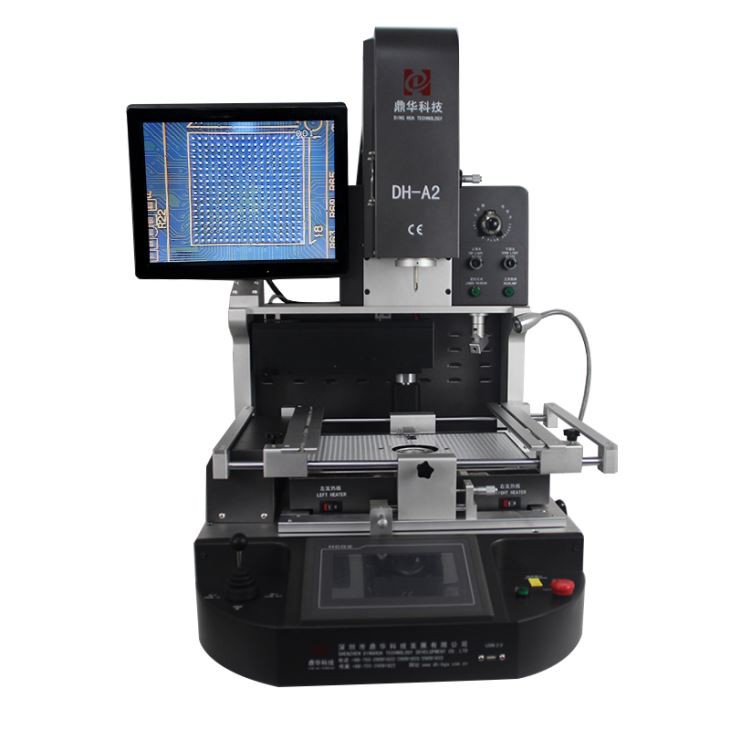

BGA Rework Soldering chaw nres tsheb

1. Dinghua DH-A2 bga rework soldering chaw nres tsheb 2. Chaw ncaj qha los ntawm Hoobkas 3. Chaw tsim khoom loj tshaj plaws ntawm automatic BGA rework chaw nres tsheb hauv Suav teb

Hauj lwm lawm

BGA rework soldering chaw nres tsheb

1.Application OfOptical Alignment BGA Chaw Tsim Kho Chaw Nres Tsheb

Muaj peev xwm kho lub motherboard ntawm lub computer, smartphone, laptop, MacBook logic board, digital koob yees duab, cua txias, TV thiab lwm yam khoom siv hluav taws xob los ntawm kev kho mob kev lag luam, kev sib txuas lus kev lag luam, tsheb kev lag luam, thiab lwm yam.

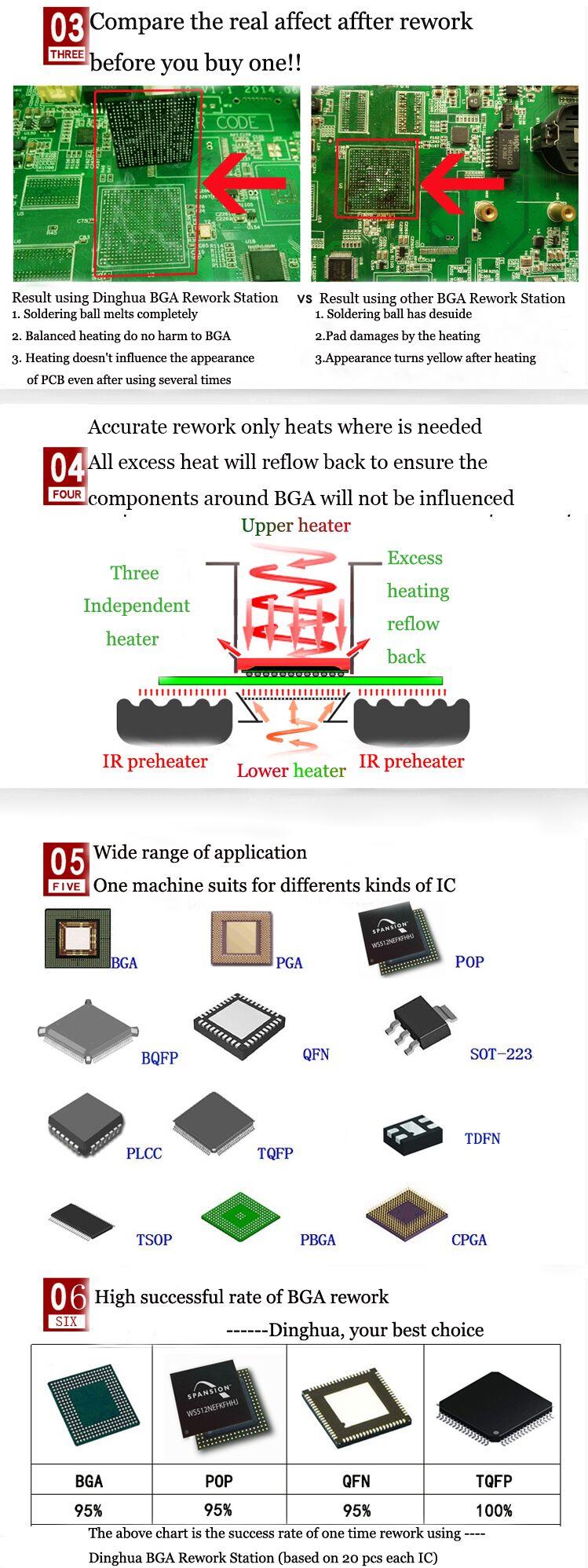

Cov tub rog, rov ua dua, tawm ntawm ntau cov chips: BGA, PGA, POP, BQFP, QFN, SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED nti.

2. khoom Muaj Cov Nta ntawm Optical Alignment BGA Reballing Chaw Nres Tsheb

Nqus plua plav-cwj mem ntsia sab saud tsis muaj qhov yooj yim, uas yooj yim rau kev tuaj tos, hloov thiab tsis kam, thiab lwm yam.

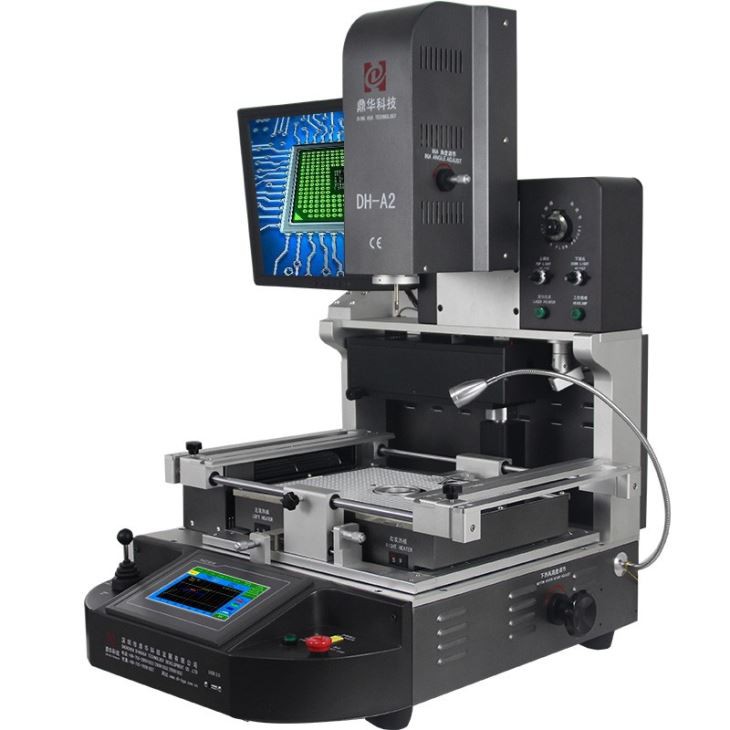

Lub vijtsam tshuaj xyuas, 1080P, 15 ntiv tes, uas yog siv rau kev sib thooj los qhia rau.

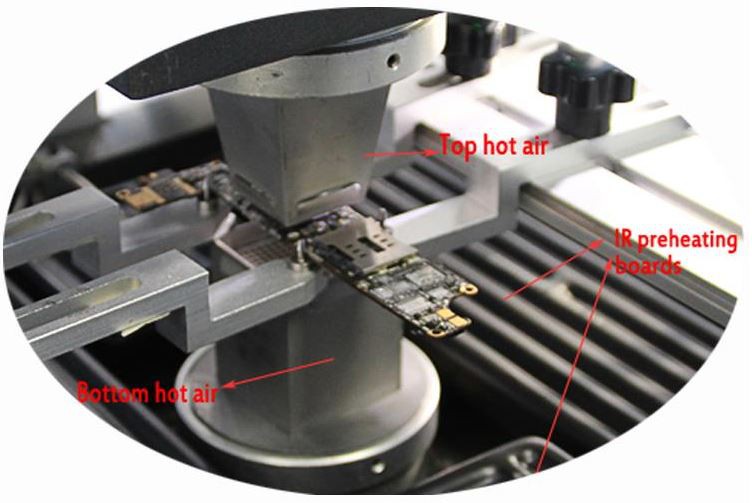

2 lub tshuab cua kub cua thiab 1 lub infrared preheating tsam, cov cua kub cua ua cua sov rau soldering thiab desoldering, infrared preheating

rau qhov loj daim hlau loj yuav tsum tau preheated thiaj li ua rau cov motherboard tiv thaiv.

Yuav lwm lub teeb pom kev zoo hauv LED, 10W, uas yog qhov kaj txaus rau ib qho loj PCB tau pom meej.

Cov hlau-ntxaij thaiv thaiv txheej yog nruab rau saum qhov chaw infrared preheating, uas tuaj yeem ua rau cov neeg ua haujlwm tiv thaiv los ntawm kev raug mob,

kuj rau cov khoom me me tsis xa sab hauv, txawm tias muaj cua sov kom zoo.

* Cov qib siab tiav ntawm kev tsim kho qib-qib. Precise kub tswj tau thiab npliag sib ncag ntawm txhua qhov sib txawv soldering.

* 3 qhov chaw muaj cua sov kom tsis txhob muaj qhov kub thiab txias. Kev sib txawv nrog ± 1ºC. Koj tuaj yeem tsim ntsuas kub sib txawv ntawm qhov screen raws cov sib txawv ntawm cov motherboard.

* 600 lab pix Panasonic thawj CCD lub koob yees duab ua kom paub tseeb tias yuav tsum tau ua kom haum txhua qhov sib txuas soldering.

* Yooj yim khiav lag luam. Tsis muaj cov txuj ci tshwj xeeb xav tau.

3.Txoj kev soj ntsuam ntawm Optical Alignment BGA Reballing Chaw Nres Tsheb

4. Vim li cas ho xaiv OurOptical Alignment BGA Reballing Station?

5.Certificate ofOptical Alignment BGA Chaw Tsim Kho Chaw Nres Tsheb

Txhawm rau muab cov khoom lag luam zoo, SHENZHEN DINGHUA TECHNOLOGY KEV LOJ HLOOV CO., LTD yog thawj dhau kev dhau UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov. Lub sijhawm no, txhawm rau txhim kho thiab zoo tshaj plaws cov txheej txheem kev ua haujlwm tau zoo, Dinghua tau dhau daim ntawv pov thawj ISO, GMP, FCCA, C-TPAT rau kev kuaj xyuas kev xaib.

6.Packing& Cov khoom xa tawm ntawmOptical Alignment BGA Chaw Teeb Txawb Chaw Nres Tsheb

7.Shipment rauChaw Ua Si Kho Kom Zoo Dua BGA Qhov Chaw Nres Tsheb

Peb yuav nkoj lub tshuab ntawm DHL / TNT / FEDEX. Yog tias koj xav tau lwm cov nqe lus xa khoom, thov qhia peb. Peb yuav txhawb koj.

8. Cov nqe lus ntawm Kev Them Nyiaj

Lub txhab nyiaj hloov pauv, Western Union, Credit Card.

Thov qhia peb yog tias koj xav tau lwm yam kev txhawb nqa.

10. Cov lus qhia me me rau Optical Alignment BGA thiab phau ntawv BGA rov ua haujlwm chaw nres tsheb:

Cov txheej txheem BGA desoldering no muaj txiaj ntsig thiab hloov maj mam, yog li nws yuav tsum muaj cov txuj ci tsim nyog thiab cov kauj ruam txhawm rau kom muaj cov txiaj ntsig zoo.Yog li txuas rau BGA chips, txhawm rau tshem tawm ya raws, PCB thiab BGA yuav tsum tau ci rau hauv qhov cub qhov kub tas li ntawm 80ml 90 ℃ rau 20 xuab moos.Ua li qhov cub ci thiab lub sijhawm raws li kev ntsuas ntawm noo noo.PCB thiab BGA yam tsis muaj qhov tsis tuaj yeem tuaj yeem txuas nrog ncaj qha.Nws yog qhov tseem ceeb yuav tsum tau them nyiaj tshwj xeeb rau kev hnav lub ntsej muag lossis cov hnab looj tes tiv thaiv thaum ua tag nrho cov hauv qab no. cov kev ua haujlwm kom tsis txhob muaj kev puas tsuaj rau BGA nti.

Ua ntej welding BGA nti, BGA nti yuav tsum tau muab kho kom haum ntawm PCB ncoo.Yog muaj ob txoj hauv kev uas siv tau: kev kho qhov muag thiab cov phau ntawv ua ke.Qhov tam sim no, phau ntawv kev sib cais yog siv ntau, uas yog, lub vijtsam luam ntawv kab ncig BGA thiab ntsuas phoo ntawm PCB tau ua raws li.

Cov txheej txheem ntawm BGA thiab PCB kev sib cais: nyob rau hauv cov txheej txheem ntawm cov kab ke ntawm BGA thiab silkscreen, txawm tias lub pob ham tsis sib txawv los ntawm cov ntaub qhwv los ntawm kwv yees li 30%, nws tseem tuaj yeem tau txais welded yog tias nws tseem tsis tau ua kom tiav.Because hauv cov txheej txheem yaj, lub pob tin yuav cia li muab kho kom haum nrog lub ntsuas phoo vim tias qhov nro ntawm nws thiab lub ncoo tin.Tom qab qhov kev ua haujlwm sib xyaw ua tiav, muab cov PCB tso rau ntawm qhov cuab yeej ntawm BGA rov qab rooj thiab ruaj ntseg nws kom nws yog qib nrog BGA xa rov qab cov lus. Xaiv qhov tsim nyog kub cua nozzle (uas yog, qhov loj ntawm lub nozzle loj dua me me tshaj BGA), tom qab ntawd xaiv qhov ntsuas kub sib xws, pib lub vuam, tos rau qhov ua tiav qhov ntsuas cua kub, txias, tom qab ua tiav BGA vuam.

Hauv kev tsim cov txheej txheem thiab kev debugging, nws yog kev tsis pom dhau los hloov BGA vim kev puas tsuaj los ntawm BGA lossis lwm yam laj thawj.Qhov BGA kho rooj kuj tuaj yeem rhuav qhov BGA.Disassembly ntawm BGA tuaj yeem raug suav hais tias yog cov txheej txheem thim rov qab ntawm vuam BGA.Qhov sib txawv yog tias tom qab qhov ntsuas cua kub nkhaus tiav lawm, BGA yuav tsum muab nqus nrog lub cwj mem xau, thiab lwm yam cuab yeej, xws li tweezers, tsis yog siv los ua kom tsis txhob muaj kev cuam tshuam los ntawm lub ncoo los ntawm kev siv ntau lub zog.Qhov PCB ntawm qhov tshem tawm BGA siv rau tshem cov tin thaum kub kub, yog li vim li cas nws yuav tsum ua haujlwm thaum nws kub? Vim tias kub kub PCB yog sib npaug rau txoj haujlwm ntawm kev ntsuas ua ntej, nws tuaj yeem ua kom paub tseeb tias kev ua haujlwm ntawm kev tshem tin yog yooj yim dua. Cov kab nruam siv nyob ntawm no, tsis txhob siv lub zog ntau dhau los ntawm kev ua haujlwm, yog li kom tsis txhob muaj kev puas tsuaj rau lub ntsuas phoo, tom qab xyuas kom meej tias lub ncoo ntawm PCB yog tiaj tus, koj tuaj yeem nkag mus rau vuam kev ua haujlwm ntawm BGA.

Kev tshem tawm BGA tuaj yeem rov txuas dua tau ntxiv.Tab sis lub pob yuav tsum cog tom qab ua ntej vuam dua.Qhov hom phiaj ntawm cog pob yog rov ua pob dua pob ntawm lub ncoo ntawm BGA, tuaj yeem ua tiav kev teeb tsa tib yam li BGA tshiab.

Nrog rau cov txuj ci saum toj no ntawm BGA vuam thiab cov txheej txheem pov tseg, yuav muaj kev qhia tsawg dua ntawm txoj kev ntawm vuam kev loj hlob, thiab cov txiaj ntsig yuav nrawm dua thiab ua tau zoo dua.Kuv cia siab tias cov kev sib koom hauv tsab xov xwm no yuav ua rau koj muaj kev tshoov siab rau BGA vuam thiab disassembly.