Circuit Board Rework Kho Tshuab

CCD Lub Koob Yees Duab Split Vision Automatic Circuit Board Rework Kho Tshuab nrog cov khoom siv reballing.

Hauj lwm lawm

Kev sib caisCircuit Board Rework Kho Tshuab

Circuit board kho tshuab yog cov cuab yeej tshwj xeeb uas siv los ua haujlwm thiab kho cov khoom siv hluav taws xob puas lossis ua tsis raug (PCBs).

Cov tshuab no siv ntau yam txuj ci los tshem tawm thiab hloov cov khoom tsis zoo, xws li soldering, desoldering, thiab cov khoom siv.

tso chaw.

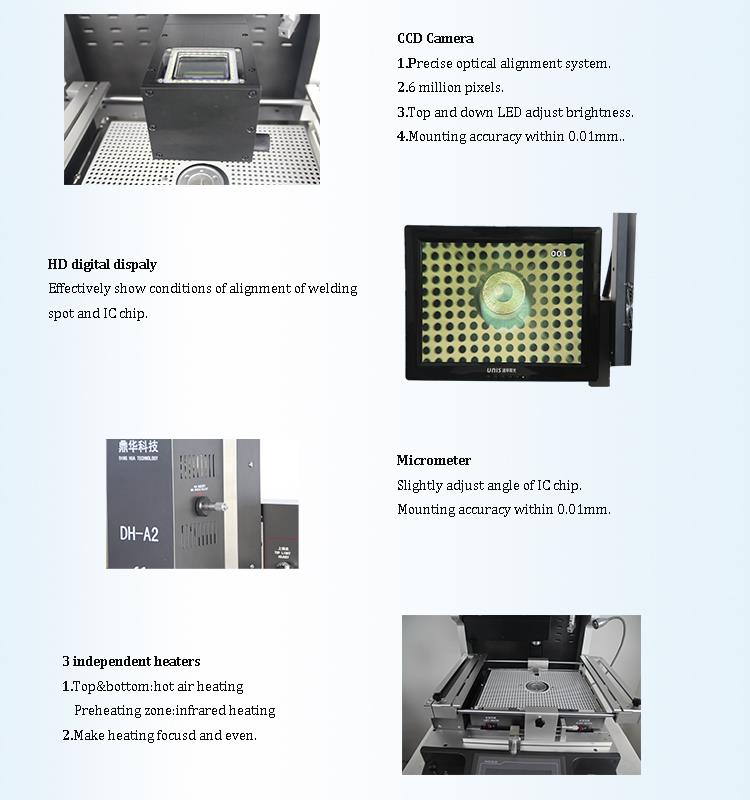

1. High-precision placement systems los xyuas kom meej qhov kev tso kawm ntawm cov khoom.

2. Cov cua sov thiab cua txias siab heev los tswj qhov kub thiab txias thaum lub sij hawm soldering thiab desoldering txheej txheem.

3. Lub tshuab nqus tsev desoldering cov cuab yeej tshem tawm cov khoom tsis ua rau PCB puas.

4. Automated component recognition systems los txheeb xyuas thiab tso cov khoom.

5. Cov neeg siv-phooj ywg interfaces uas tso cai rau cov neeg siv los tswj thiab saib xyuas cov txheej txheem kho.

1.Application Of Split vision

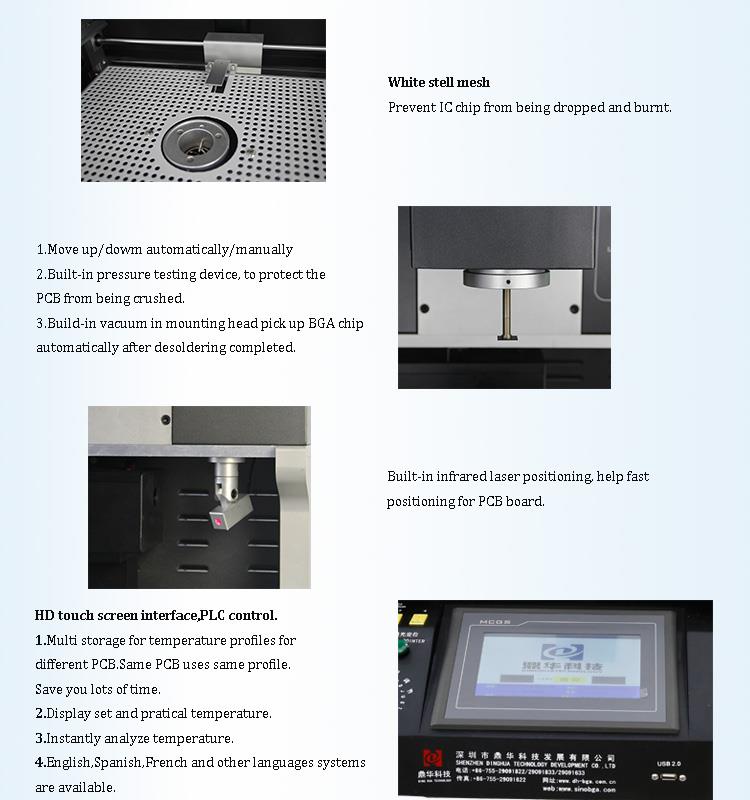

Tshem tawm, kho, hloov Solder, reball, desoldering ntau hom chips: piv txwv li: BGA, PGA, POP, BQFP, QFN,

SOT223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED nti.

2.Qhov zoo ntawm laser txoj hauj lwm Circuit Board Rework Kho Tshuab

-

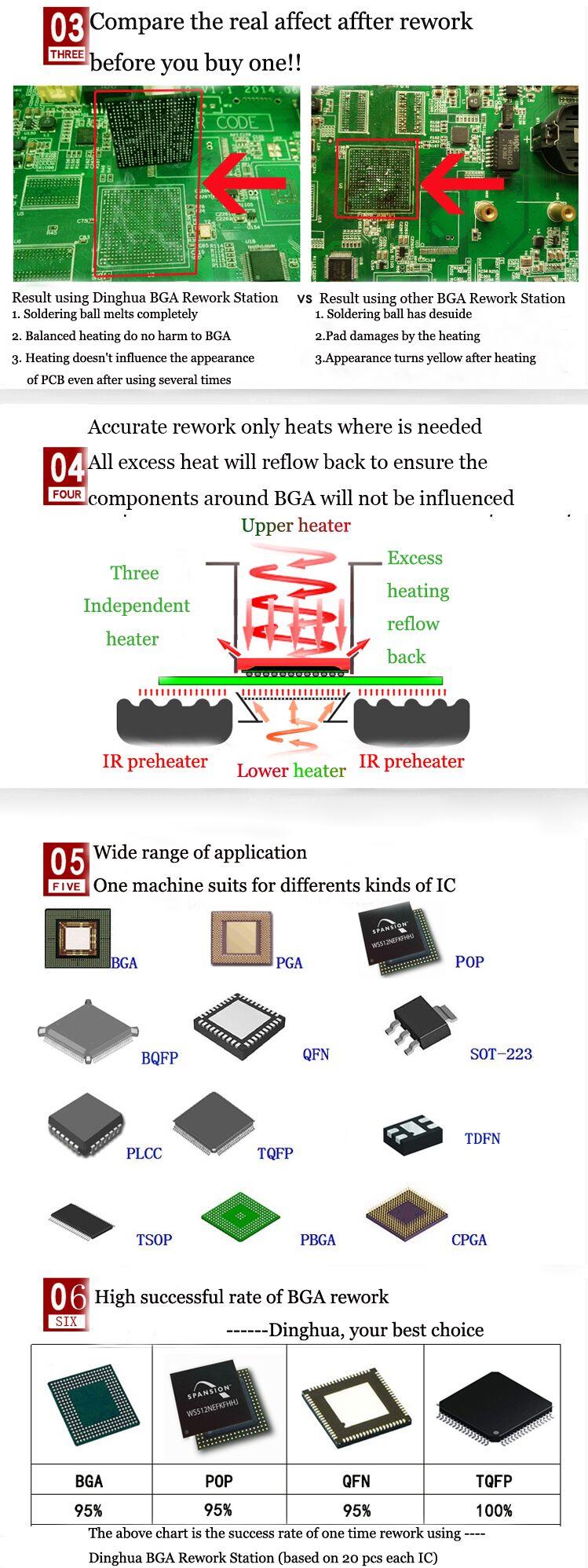

Embedded muaj computer, high-txhais kov screen txiv neej-tshuab interface, PLC tswj, ib qho instantaneous nkhaus tsom xam muaj nuj nqi. Real-time zaub teeb tsa thiab ntsuas kub nkhaus, thiab tsom xam thiab kho qhov nkhaus.

2. High-precision K-hom thermocouple kaw-voj tswj thiab kub tsis siv neeg them nyiaj system, ua ke nrog PLC thiab ntsuas kub kom ua tiav qhov ntsuas kub zoo, ua kom qhov kub sib txawv ntawm ± 2 degrees. Nyob rau tib lub sijhawm, qhov ntsuas kub sab nraud interface paub qhov tseeb ntawm qhov ntsuas kub. Thiab ua tiav qhov tseeb tsom xam thiab kev ua pov thawj ntawm qhov ntsuas kub nkhaus.

3. Specification ntawm laser positioning

| zog | 5300W |

| Lub tshuab cua sov sab saum toj | Cua kub 1200W |

| Hauv qab rhaub | Cua kub 1200W.Infrared 2700W |

| Fais fab mov | AC220V ± 10% 50/60Hz |

| Dimension | L530 * W670 * H790 hli |

| Qhov chaw | V-groove PCB kev txhawb nqa, thiab nrog rau sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | K hom thermocouple, kaw voj tswj, ywj siab cua sov |

| Kub qhov tseeb | ± 2 degree |

| PCB loj | Max 450 * 490 mm, Min 22 * 22 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, ± 15mm sab xis / sab laug |

| BGAchip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 1 (yeem) |

| Net nyhav | 70kg ua |

4. Cov ntsiab lus ntawmTsis Siv Neeg Cua Kub

5.Vim li cas thiaj xaiv peb Infrared Circuit Board Rework Kho Tshuab?

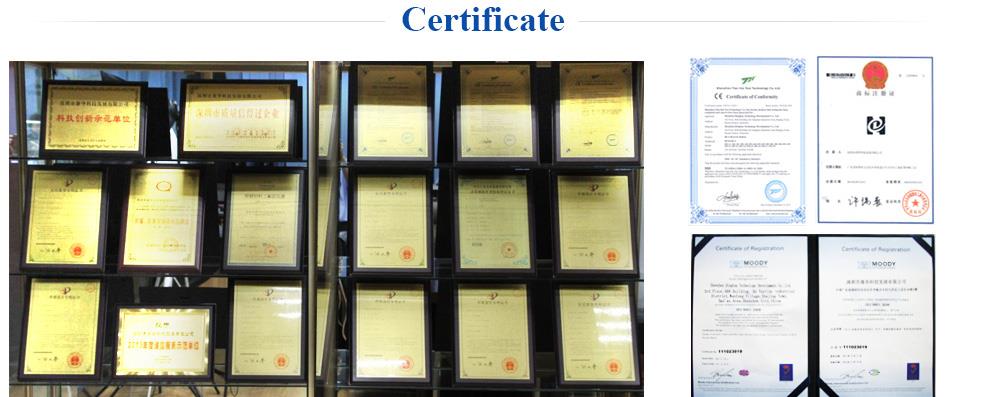

6. Daim ntawv pov thawj ntawm Optical Alignment

UL, E-MARK, CCC, FCC, CE ROHS daim ntawv pov thawj. Lub caij no, txhawm rau txhim kho thiab ua kom zoo tshaj qhov system, Dinghua

tau dhau ISO, GMP, FCCA, thiab C-TPAT ntawm qhov chaw kuaj ntawv pov thawj.

7.Packing & shipping ntawm CCD lub koob yees duab

8. Kev paub txog Circuit Board Rework Repair Machine

ESD tiv thaiv rau Circuit Board Rework Repair Tshuab

Kev tiv thaiv hluav taws xob hluav taws xob (ESD) yog qhov tseem ceeb rau cov kws tsim khoom siv kho vajtse tsim thiab tsim khoom. Ntau tus neeg tsim khoom feem ntau ntsib cov xwm txheej uas cov khoom tsim hauv chav kuaj tau dhau tag nrho cov kev xeem, tab sis tom qab cov neeg siv khoom siv lawv rau lub sijhawm, qhov tshwm sim txawv txav tshwm sim, thiab qhov ua tsis tiav yuav tsis siab heev. Feem ntau, feem ntau ntawm cov teeb meem no yog tshwm sim los ntawm surges, ESD ntaus, thiab cov teeb meem zoo sib xws. Hauv kev sib dhos thiab kev tsim khoom ntawm cov khoom siv hluav taws xob, ntau dua 25% ntawm kev puas tsuaj rau cov khoom siv hluav taws xob semiconductor yog ntaus nqi rau ESD. Nrog rau kev siv tshuab microelectronics thoob plaws thiab qhov nyuaj ntawm ib puag ncig electromagnetic, muaj kev mloog zoo rau qhov cuam tshuam ntawm electromagnetic teb ntawm electrostatic paug, xws li electromagnetic cuam tshuam (EMI) thiab electromagnetic compatibility (EMC) rau Circuit Board Rework Repair Machines.

Cov kws tsim hluav taws xob tsim hluav taws xob feem ntau ntxiv kev tiv thaiv siv ntau yam khoom siv hluav taws xob hloov hluav taws xob (TVS), xws li cov khoom siv (diodes), hlau oxide varistors (MOVs), thyristors, cov khoom siv polymer tshiab, cov raj roj, thiab cov pa taws yooj yim. Nrog rau qhov tshwm sim ntawm lub cim tshiab ntawm high-speed circuits, kev khiav hauj lwm zaus ntawm cov khoom siv tau nce los ntawm ob peb kHz mus rau GHz, ua rau qhov kev thov rau cov khoom siv muaj peev xwm siab rau ESD tiv thaiv. Piv txwv li, TVS cov khoom siv yuav tsum teb sai sai rau cov khoom siv hluav taws xob tuaj. Thaum qhov hluav taws xob hluav taws xob nce mus txog 8 kV (lossis siab dua) ntawm qhov siab tshaj ntawm 0.7 ns, qhov cuam tshuam lossis kev tswj hwm qhov hluav taws xob ntawm TVS ntaus ntawv (sib npaug rau cov kab nkag) yuav tsum qis txaus kom ua tau zoo.

ON Semiconductor's NUC2401 yog hom hom lim uas muaj kev sib xyaw ua ke uas tsis muaj peev xwm ESD tiv thaiv uas muab cov bandwidth tsim nyog rau kev kub ceev USB 2.0 cov teeb liab, tsim nyog hom-hom attenuation, thiab rhiab hauv Circuit Court ESD tiv thaiv kom muaj teeb liab kev ncaj ncees. Vishay's VBUS054B-HS3 yog ib qho kev daws teeb meem ESD ib leeg nrog qhov sib txawv me me ntawm kab capacitances, tsim los tiv thaiv dual-ceev USB chaw nres nkoj los ntawm cov teeb liab voltage. Nws tseem tuaj yeem clamp qhov tsis zoo uas yog me ntsis hauv av theem thaum clamping qhov zoo nyob rau hauv qhov ntsuas hluav taws xob me ntsis siab dua 5 V rau Circuit Board Rework Repair Machines.

Niaj hnub no, cov kws tsim hluav taws xob tsim hluav taws xob tau nce zuj zus siv ESD cov phiaj xwm kev tawm tsam hauv kev tsim hluav taws xob ntau zaus. Txawm hais tias tus nqi qis silicon diodes (los yog varistors) muaj qhov cuam tshuam tsawg heev / clamp voltages, lawv lub peev xwm muaj peev xwm thiab cov xau tam sim no tsis tuaj yeem ua tau raws li qhov xav tau ntawm daim ntawv thov. Lub polymer ESD suppressor muaj qhov attenuation ntawm tsawg dua 0.2 dB ntawm zaus mus txog 6 GHz, thiab nws qhov cuam tshuam rau hauv Circuit Court yog yuav luag tsis pom zoo rau Circuit Board Rework Repair Machines.

Electromagnetic compatibility thiab kev tiv thaiv Circuit Court yog ib qho teeb meem uas tsis tuaj yeem zam hauv kev tsim ntawm txhua yam khoom siv hluav taws xob. Ntxiv nrog rau kev paub txog EMC cov qauv, cov kws tsim hluav taws xob tsim hluav taws xob yuav tsum xav txog kev ua haujlwm ntawm cov cuab yeej nws tus kheej, cov kab mob tsis zoo, cov khoom lag luam, tus nqi, thiab txhua qhov kev ua haujlwm hauv kev tsim qauv. Los ntawm layout thiab routing optimization, engineers muaj peev xwm ntxiv decoupling capacitors, magnetic hlaws, magnetic rings, shielding, PCB resonance suppression, thiab lwm yam kev ntsuas los xyuas kom meej tias EMI nyob rau hauv cov kev txwv. Thaum tsim cov qauv kev tiv thaiv hluav taws xob, cov kauj ruam tseem ceeb tshaj plaws yog ua ntej nkag siab txog cov kev daws teeb meem thiab kev tsim qauv, thiab tom qab ntawd xaiv cov khoom siv tiv thaiv ESD tsim nyog raws li.