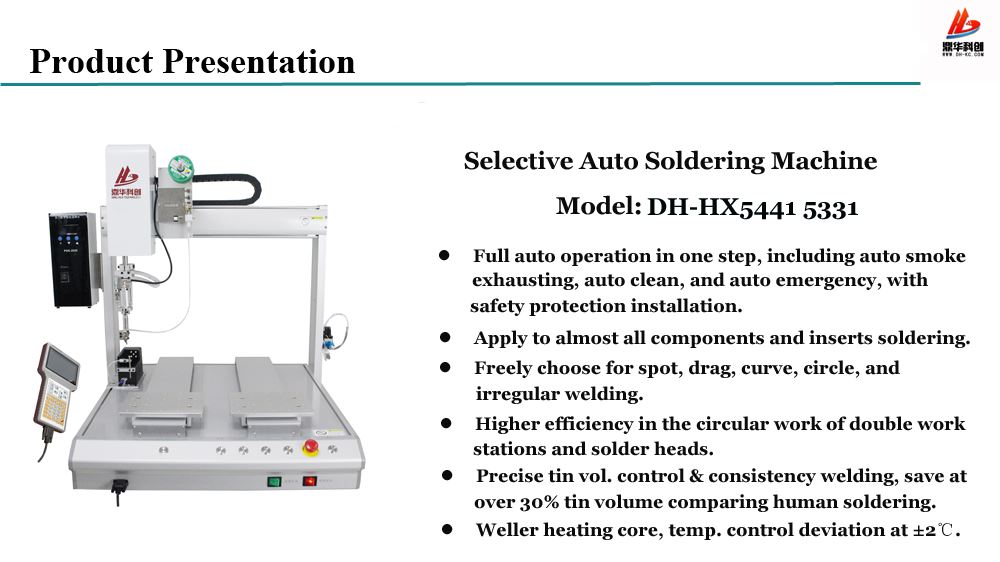

Automated soldering tshuab

Hauj lwm lawm

ROBOTIC SOLDERING MACHINE (ib leeg X Ob chav Y)

MODEL NO. DH-HX5331 & HX5441

Demo Video:

● Ib-kauj ruam: nws pib haus luam yeeb tawm, pib huv, tsis siv neeg kub ceev;

● Siv rau feem ntau tivthaiv thiab plugin sodering rau motherboards;

● Dawb xaiv rau qhov chaw, luag, nkhaus, lub voj voog, thiab vuam tsis sib xws;

● Precise tin vol. tswj & sib xws welding, ua hauj lwm tawm dab tsi tib neeg txhais tes ua tsis tau thiab ua rau lwm yam soldering shortcomings;

● Branded cua sov tub ntxhais, nrog kub sib txawv ntawm ± 5 degree;

● Lub sij hawm thiab ceev ntawm tin pub yog adjustable.

I: Technical Parameters

|

Qauv |

DH-HX5331 |

DH-HX5441 |

|

|

Axis naj npawb |

5 axis synchronous kev |

||

|

Kab |

X axis |

500 hli |

500 hli |

|

Y 1 axis |

300 hli |

400 hli |

|

|

Y 2 axis |

300 hli |

400 hli |

|

|

Z axis |

100 hli |

100 hli |

|

|

R axis |

360 degree |

360 degree |

|

|

Max bearing load |

10kg rau txhua qhov chaw nres tsheb |

||

|

Max ceev |

X axis |

800mm / sec. |

|

|

Y1/Y2 axis |

800mm / sec. |

||

|

Z axis |

450mm / sec. |

||

|

R axis |

360 degree / sec. |

||

|

Rov qab precision |

X axis |

± 0.02mm |

|

|

Y1/Y2 axis |

± 0.02mm |

||

|

Z axis |

± 0.02mm |

||

|

R axis |

± 0.02 degree |

||

|

Max khoom loj |

280 * 250 hli (X, Y) |

280 * 350 hli (X, Y) |

|

|

Khaws Cov Kev Pabcuam |

999 ua profile |

||

|

Tsav system |

Kaw-loop |

||

|

Tswj qhov system |

Movement tswj qhov system |

||

|

Qhov kub thiab txias |

40-450 degree |

||

|

Kub precision |

± 2 degree |

||

|

Cua sov lub taub hau tswb ntau |

2-99 degree |

||

|

Pub |

Tib tin feeding system |

||

|

Lub zog cua sov |

200w |

||

|

Tin pub ceev |

0 - 50 mm/s |

||

|

Tin diam |

Φ0 3-Φ1.2(tus qauv) |

||

|

Tswb |

Tin tawg, Tin thaiv, cua sov tswb |

||

|

Dimension |

L880 * W600 * H830mm |

L880 * W700 * H830mm |

|

|

Tswv yim |

AC220V ± 10% 50 / 60Hz 450VA |

||

|

Cua siab |

0 4-0.8Mpa |

||

|

Cov av noo |

20-95% |

||

|

Ua haujlwm kub |

-10-45 degree |

||

|

Net nyhav |

90kg ua |

95kg ua |

|

II: Description

1. 5 axis tsis siv neeg soldering neeg hlau

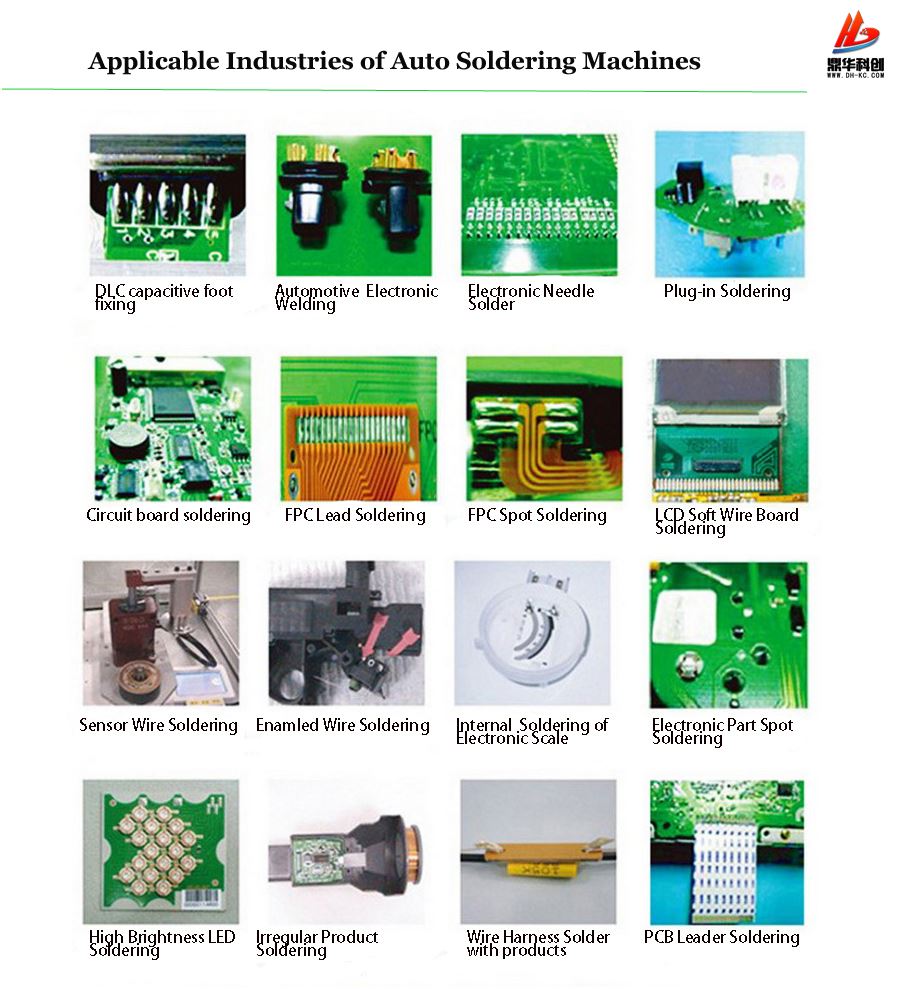

2. Thov rau qhov chaw vuam, rub vuam, nkhaus vuam, lub voj voog vuam, tsis tu ncua nkhaus nruam vuam.

3. Qhov kev pab cuam tuaj yeem luam tau.

4. Ntau tshaj 999 cov kev pab cuam tuaj yeem khaws cia, cov kev pab cuam sib txawv tuaj yeem hloov pauv yooj yim rau cov khoom sib txawv nrog ib lub pob, tsis tas yuav rov ua haujlwm dua.

5. Customization yog xaiv tau.

III: Kev ua haujlwm

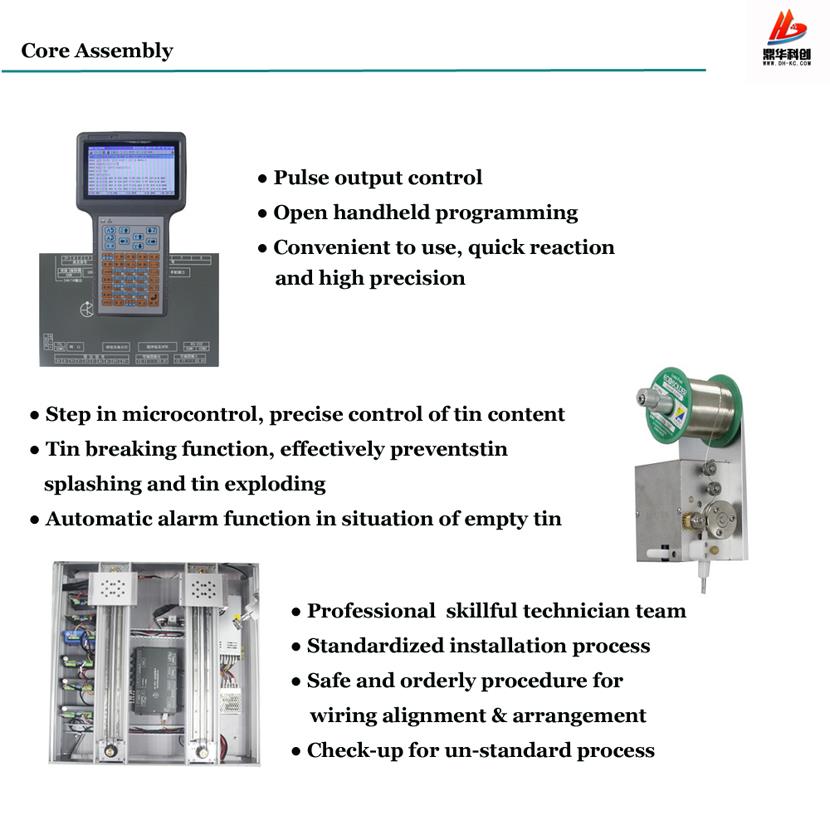

1. Muaj peev xwm input coordinates los ntawm txhaj "programming", qhov kev pab cuam yuav muab luam los ntawm point mus point los yog segment rau segment kom txuag tau lub sij hawm ntawm programming, yooj yim kawm. Qhov chaw thiab txoj kev ntawm soldering tuaj yeem hloov kho tag nrho.

2. Muaj peev xwm ua haujlwm ceev ceev qhov chaw soldering thiab coj lub vuam taub hau mus rau txoj hauj lwm ntawm soldering, tuaj yeem hloov lub sij hawm luv luv ntawm ob qho khoom siv los siv lub voj tsis nres thiab txhim kho qhov ua tau zoo los ntawm kev ua haujlwm ntawm kev qhia pendant yooj yim.

3. Ntau tshaj 999 qhov kev pab cuam profile tuaj yeem khaws cia, ib lub tshuab tuaj yeem ua 999 cov khoom sib txawv los ntawm kev ua haujlwm.

4. Qhov tsis sib txawv ntawm qhov sib txawv tuaj yeem hloov pauv hloov tau yooj yim, qhov kev pab cuam calibration ua tiav kev sib koom ua haujlwm them nyiaj tau txais txiaj ntsig, nrog calibration ntawm kev sib hloov thiab kho kev ua haujlwm tsis raug. Qhov parameter ntawm txhua qhov chaw soldering tuaj yeem teeb tsa.

5. Thov rau qhov chaw vuam, rub vuam, nkhaus vuam, lub voj voog vuam thiab vuam tsis sib xws, tag nrho cov vuam tsis tuaj yeem raug teeb tsa los ntawm cov neeg siv rau kev ua haujlwm vuam nyuaj thiab micro vuam ua haujlwm.

6. Lus Askiv version interface yog ib qho yooj yim rau cov neeg siv debug txawm tsis qhia pendant.

7. Tsis siv neeg tin pub, kom muaj nuj nqis ntawm tin tuaj yeem hloov kho thiab tswj tau meej. Tin tuaj yeem pub tau txhua lub sijhawm los thov kev sib txawv ntawm cov vuam thiab txhim kho kev ua haujlwm.

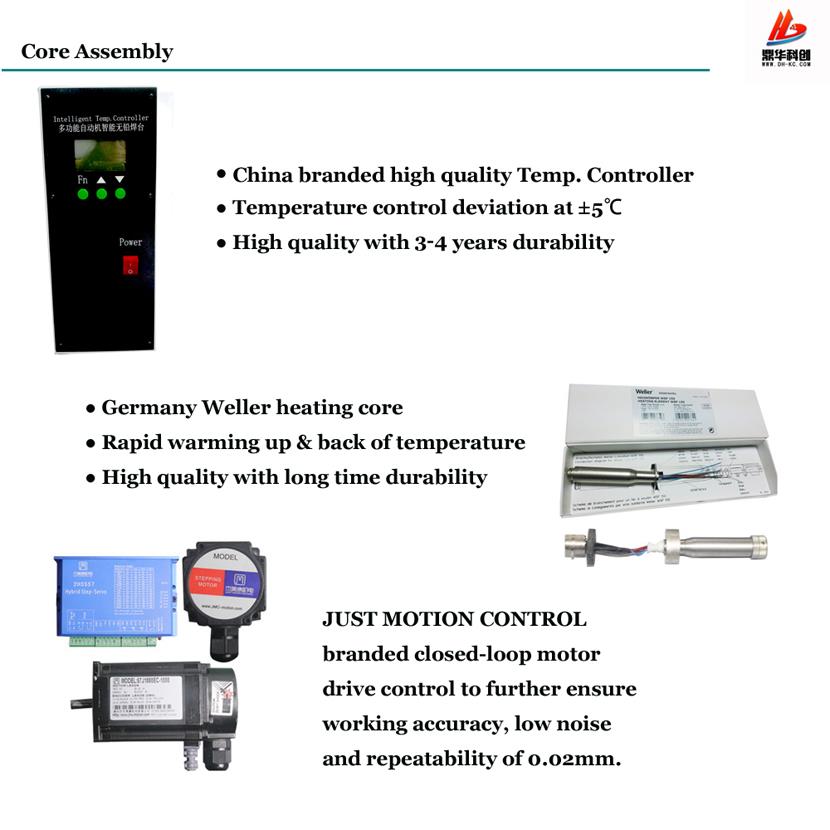

8. Weller cua sov lub taub hau, qhov kub thiab txias tuaj yeem tswj tau qhov tseeb rau ± 2 degree, lub sijhawm thiab ceev ntawm tin pub tuaj yeem hloov kho kom ua tiav cov vuam zoo.

9. Ntau lub tswv yim yog xaiv tau rau cov qauv array vuam.

10. Cov kev khaws cia vuam siv tau txhua lub sijhawm kom txuag tau lub sijhawm ntawm kev ua haujlwm.

11. Ntau yam soldering robots tuaj yeem ua haujlwm ua ke los ntawm kev tswj hwm lub computer thiab programming.

12. Nrog kev sau cov pa luam yeeb tsis siv neeg thiab nws pib ua haujlwm huv.

IV: Qhov zoo

1. Nrog kev sau cov pa luam yeeb tsis siv neeg los ua kom huab cua huv (yeem).

2. High-strength solder lub taub hau tuaj yeem hloov kho kom zoo melding.

3. Qhov kev pab cuam tuaj yeem ceev ceev los ntawm kev rov teeb tsa, ntxig thiab tshem tawm qhov chaw ntawm cov soldering lossis tag nrho kev hloov kho.

4. Clamping qhov kom yooj yim nqa thiab hloov cov khoom.

5. Pub tins txhua lub sijhawm los thov rau ntau qhov vuam thiab ua haujlwm siab.

6. Weller soldering kub tswj, tswj qhov kub thiab txias ntau dua thiab ruaj khov dua.

7. Nws pib anti-collapse.

8. Programming nrog kev qhia pendant rau txhua tus neeg siv tshiab ua haujlwm hauv 2 teev.

9. Nws pib thauj daim kab xev yog xaiv tau rau tag nrho tsis siv neeg.

10. Hom ntawm ob tus neeg siv kev tswj hwm ntawm txoj cai sib txawv rau engineer thiab tus neeg teb xov tooj.

11. Nrog kev ua haujlwm ntawm calibration ntawm R axis, kho cov haujlwm tsis raug.

12. ±0.02mm rov ua qhov tseeb kom ua tiav qhov tseeb soldering.

V: Cov Txheej Txheem

|

Tsis muaj. |

Khoom npe |

Hom |

|

1 |

Tshuab lub cev |

Dinghua |

|

2 |

Kab rov tav guid rail |

Customized los ntawm Taiwan |

|

3 |

Close-loop motor thiab tsav tsheb |

Leadshine |

|

4 |

Belt + kaw-loop |

Mikipulley |

|

5 |

Hwj chim |

txhais tau zoo |

|

6 |

Photoelectric sensor |

Omron |

|

7 |

Relay |

Omron |

|

8 |

Ua Sensor |

Omron |

|

9 |

Lub rhaub |

Weller |

III Ntim & Xa khoom

VI: Tuam txhab Profile

SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD yog Tuam Tshoj ua cov chaw tsim khoom, tsim nyob rau hauv 2011.Nws yog lub Hoobkas ncaj, tsim, tsim, muag, thiab xa tawm ntawm ib kab, tau koom nrog BGA rework chaw nres tsheb, tsis siv neeg soldering tshuab thiab neeg hlau, tsis siv neeg ntsia hlau xauv tshuab thiab cov neeg hlau, cov tshuab tsis siv neeg dispenser, nrog rau kev lag luam rau CNC engraving tshuab, LCD cov khoom, thiab SMT cov khoom siv thiab cov khoom siv. Peb tau cog lus los muab cov cuab yeej siv siab tshaj plaws nrog cov khoom zoo thiab kev pabcuam raws sijhawm rau peb cov neeg siv khoom.

Raws li ib tug ntawm cov pioneer nyob rau hauv no kev lag luam, peb txuas ntxiv txhim kho thiab innovate nrog rau lub lag luam xav tau los ntawm absorbing lub advanced kev loj hlob ntawm txawv teb chaws thiab ua raws li peb lub zeem muag ntawm 'Professionalism, Honesty, Innovative thiab lub luag hauj lwm'.

Muab cov cuab yeej technology yog peb lub hom phiaj tseem ceeb. Los ntawm kev ua haujlwm pab pawg, peb tau ua tiav cov thev naus laus zis thev naus laus zis nrog rau patent. Nyob rau tib lub sijhawm, peb cov khoom lag luam npog 3 pawg: high-end, nruab nrab-kawg thiab qis-kawg rau kev txhim kho thiab tsim khoom siv phau ntawv, semi-auto mus rau tag nrho cov txheej txheem automated. Peb cov kev lag luam tau nthuav dav rau hauv kev lag luam xws li: kev kho tus kheej, cov chaw tsim khoom, kev kawm, tub rog thiab aerospace thiab lwm yam. Tib lub sijhawm, peb tau tsim cov ntsiab lus ntawm kev muag khoom thiab kev pabcuam kawg hauv zos thiab txawv teb chaws. Peb tau nce qib hauv kev lag luam thoob ntiaj teb ncaj qha, nrog cov khoom lag luam zoo, cov nqi sib tw, thiab kev tshawb nrhiav kev lag luam xav tau, thiab tau koom tes nrog ntau tus neeg koom tes zoo xws li Google, FOXCUNN, Lenovo, Sumsung, Huawei, thiab lwm yam.

Koj qhov kev txaus siab yog peb txoj kev nrhiav, ua raws li cov neeg siv khoom, tsom mus rau kev lag luam, peb lub tuam txhab muab cov khoom lag luam nrig thiab cov kev pabcuam zoo rau cov neeg siv khoom los ntawm kev nruam ntej. Peb zoo siab ua haujlwm nrog koj los tsim kom muaj lub neej yav tom ntej.

V.FAQ ntawm tsis siv neeg soldering neeg hlau

Q1: Kuv tsis paub dab tsi txog lub tshuab soldering tsis siv neeg, hom tshuab twg kuv yuav tsum xaiv?

Cia li qhia peb seb koj xav ua dab tsi siv lub tshuab no. Thiab xa peb cov qauv duab zoo dua.

Tom qab ntawd peb yuav xa koj cov kev daws teeb meem zoo meej thiab cov lus qhia.

Q2: Thaum kuv tau txais lub tshuab no, tab sis kuv tsis paub yuav siv nws li cas. Kuv yuav ua li cas?

Peb yuav xa koj phau ntawv txhais lus Askiv thiab CD video rau lub tshuab siv thiab tswj nrog lub tshuab. Yog tias koj tseem muaj qee qhov tsis ntseeg, peb tuaj yeem tham hauv xov tooj lossis los ntawm WHATSAPP / SKYPE. Peb tus engineer kuj tuaj yeem xa tuaj rau koj lub tebchaws los nruab lossis kho tshuab yog tias tsim nyog.

Q3: Yog tias qee qhov teeb meem tshwm sim rau lub tshuab no thaum lub sijhawm lav, kuv yuav ua li cas?

Peb yuav muab cov khoom pub dawb rau lub tshuab no thaum lub sijhawm lav yog tias lub tshuab muaj teeb meem.Peb kuj muab kev pabcuam dawb tom qab mus tas li. Yog li txhua yam tsis ntseeg, tsuas yog qhia rau peb paub, peb yuav muab cov kev daws teeb meem rau koj hauv 30 min.

Zoo siab txais tos txhua tus neeg koom tes thoob ntiaj teb los sab laj thiab tuaj xyuas peb lub Hoobkas!