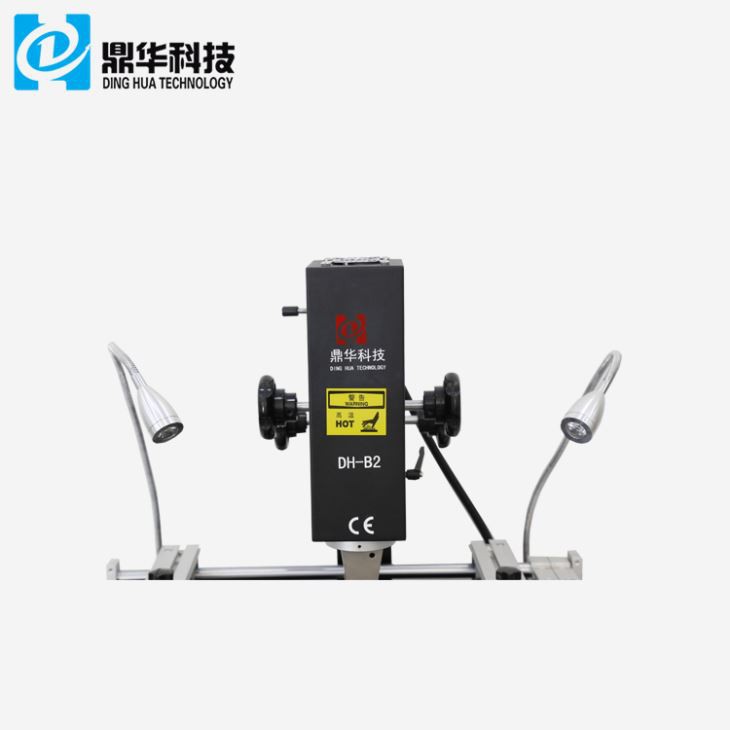

Infrared Kov Screen SMD Rework Chaw nres tsheb

Rework Chaw nres tsheb yog qhov system uas nws yog rau soldering thiab de-soldering rau chav tsev ntawm lub rooj tsavxwm. Cov chav tsev yuav yog thaj chaw me me ntawm lub rooj tsavxwm ib txwm, Yog li ntawd, lub rooj tsavxwm yuav raug cua sov hauv ib qho chaw me me xwb. Nyob rau hauv cov ntaub ntawv no, lub rooj tsavxwm yuav warp nrog cua sov thiab nyob ib sab qhov chaw yuav tau txais kev puas tsuaj nrog cua sov.

Hauj lwm lawm

Infrared Kov Screen SMD Rework Chaw nres tsheb

1. Khoom nta ntawm infrared kov screen SMD rework chaw nres tsheb

1. Airflow thiab kub yog adjustable nyob rau hauv ib tug dav ntau yam los tsim ib tug high-temperature breeze.

2. Lub taub hau cua sov txav tau yooj yim rau kev khiav lag luam, lub taub hau kub cua thiab lub taub hau mounting yog manually

tswj, PCB zawv zawg khib yog micro-adjustable nrog x. Thiab. Y-axis.

3. Kov npo interface, plc tswj, muaj peev xwm tso saib qhov kub thiab txias nkhaus thiab ob qhov ntsuas qhov nkhaus

tib lub sijhawm.

4. Ob qhov chaw ua cua sov ywj siab, qhov kub thiab lub sijhawm yog digitally tso tawm.

5. Cov kev txhawb nqa rau BGA soldering kev txhawb nqa ncej yog micro-adjustable los tswj cov dej hauv zos

nyob rau hauv qhov chaw soldering.

2.Specification ntawm infrared kov screen SMD rework chaw nres tsheb

3.Cov ntsiab lus ntawm infrared kov npo smd rework chaw nres tsheb

HD kov npo interface;

2.Peb lub tshuab hluav taws xob ywj pheej ( cua kub & infrared );

3. Nqus cwj mem;

4.Led headlamp.

4.Vim li cas thiaj xaiv Peb lub infrared kov npo smd rework chaw nres tsheb?

5.Certificate ntawm infrared kov screen smd rework chaw nres tsheb

6.Packing & Shipping ntawm infrared kov screen smd rework chaw nres tsheb

7. Hu rau peb

Email: john@dinghua-bga.com

WhatsApp/Wechat/Mob:+86 157 6811 4827

8.Kev paub txog

Kev ceev faj ntawm BGA rework

1.Preheat txhais: Preheating heats tag nrho cov sib dhos hauv qab lub melting point ntawm solder thiab lub

reflow kub.

Qhov zoo ntawm preheating: Ua kom cov flux, tshem tawm cov oxides thiab cov yeeb yaj kiab saum npoo ntawm cov hlau yuav tsum tau welded

thiab cov volatiles ntawm cov flux nws tus kheej, txhim khu cov nyhuv wetting, txo qhov kub qhov sib txawv ntawm

sab sauv thiab qis PCB, tiv thaiv kev puas tsuaj thaum tshav kub kub, tshem tawm cov dej noo, thiab tiv thaiv qhov tshwm sim ntawm paj kws,

txo qhov kub qhov sib txawv.

Preheating txoj kev: Muab PCB tso rau hauv qhov cub rau 8 mus rau 20 teev ntawm qhov kub ntawm 80 txog 100 degree

(nyob ntawm qhov loj ntawm PCB).

2. "Popcorn": hais txog qhov muaj dej noo nyob rau hauv ib qho kev sib txuas los yog SMD ntaus ntawv thaum lub vuam

txheej txheem sai rhuab, kom ya raws expansion, qhov tshwm sim ntawm micro-cracking.

3. thermal puas muaj xws li: ncoo lead warping; substrate delamination, dawb me ntsis, blistering los yog discoloration.

Intrinsic warping ntawm substrate thiab degradation ntawm nws Circuit Court ntsiab yog tshwm sim los ntawm "invisibility" teeb meem,

vim qhov sib txawv expansion coefficient ntawm cov khoom sib txawv.

4. Peb txoj kev rau PCB preheating nyob rau hauv qhov chaw los yog rework:

Qhov cub: BGA cov dej noo sab hauv tuaj yeem ci los tiv thaiv paj kws thiab lwm yam tshwm sim

Kub phaj: Txoj kev no tsis yog siv vim tias cov cua sov seem hauv cov phaj kub thaiv qhov cua txias ntawm

solder sib koom ua ke, ua rau nag lossis daus ntawm cov hlau lead, tsim cov pas dej ua ke, thiab txo lub zog ntawm cov hlau sib txuas.

Cov cua kub trough: Txawm hais tias cov duab thiab cov qauv hauv qab ntawm PCB sib dhos, lub zog cua kub tuaj yeem ua tau

ncaj qha nkag mus rau txhua lub ces kaum thiab cov kab nrib pleb ntawm PCB los ua ke, kom lub PCB tuaj yeem ua kom sov sib npaug, thiab cov cua sov

sij hawm luv luv.