Tsis siv neeg PCB Soldering Tshuab

1. Dinghua Tsis Siv Neeg PCB Soldering Tshuab2. Spot vuam, rub vuam thiab arc vuam muaj 3. Customized kev pabcuam tuaj yeem muab.4. Lub sij hawm xa tuaj: 5-15 hnub ua haujlwm.

Hauj lwm lawm

Kev lag luam ntawm cov khoom siv hluav taws xob tsis tau nce qib thiab ua haujlwm zoo li tam sim no, ua tsaug rau kev loj hlob

nyob rau hauv technologies xws li tsis siv neeg PCB soldering tshuab. Lub tshuab no tau zoo heev simplified cov txheej txheem ntawm

Circuit board sib dhos, ua kom sai thiab yooj yim dua rau cov tuam txhab hluav taws xob.

kev txhim kho hauv kev tsim khoom. Nws yog tsim los solder hluav taws xob Cheebtsam mus rau PCBs txiav,

nrog high precision thiab raug, guaranteeing high-zoo tau.

Lub tshuab tau ua haujlwm tau zoo heev, vim nws tuaj yeem ua haujlwm ntawm tus nqi nrawm dua piv rau phau ntawv soldering.

Tsis tas li ntawd, nws txo qis qhov ua yuam kev uas tuaj yeem tshwm sim nrog phau ntawv soldering, uas tuaj yeem ua rau muaj kev puas tsuaj rau cov khoom siv hluav taws xob.

ua ke.

Kev siv lub tshuab tsis siv neeg PCB soldering hauv kev lag luam hluav taws xob tsim khoom tsis yog nce ntxiv

efficiency thiab qhov tseeb tab sis kuj nce qhov zoo ntawm cov khoom siv sib dhos. Lub tshuab tau pab txo qis

khib nyiab loj, thiab nws yog ib qho kev nqis peev zoo rau cov tuam txhab uas xav nyob hauv kev lag luam mus ntev.

Nrog lub tshuab tsis siv neeg PCB soldering, cov tuam txhab tam sim no tuaj yeem ua raws li qhov xav tau thiab tsim khoom ntau dua

nyob rau hauv lub sij hawm luv luv. Qhov no tau ua rau muaj kev nce hauv cov zis thiab cov nyiaj tau los rau kev tsim khoom siv hluav taws xob

cov tuam txhab, uas tau coj kev loj hlob tseem ceeb rau kev lag luam.

lub tshuab tsis siv neeg PCB soldering yog ib qho kev tsim kho tshiab hauv kev lag luam hluav taws xob uas tau coj los

txog cov txiaj ntsig suav tsis txheeb. Nws tau zoo heev txhim kho efficiency, raug, thiab zoo nyob rau hauv hluav taws xob manufacturing, ua

mus rau ib tug tseem ceeb txo nyob rau hauv nkim thiab nce nyob rau hauv profit margins.

1. Qauv

A. Ib lub taub hau, ib qho chaw nres tsheb, (R axis)

B. Ib lub taub hau, ob qhov chaw nres tsheb, (R axis)

C. Ob lub taub hau, ib qho chaw nres tsheb, (R axis)

D. Ob lub taub hau, ob qhov chaw nres tsheb, (R axis).

E. Lwm cov qauv tsim muaj. Txais tos tiv tauj peb.

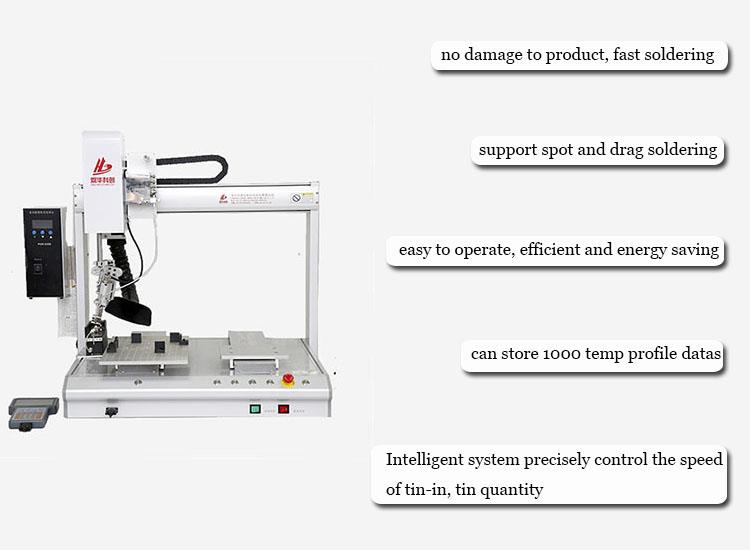

2. Cov yam ntxwv

3. Daim ntawv thov

Kev lag luam kev sib txuas lus: Apple cov ntaub ntawv cov ntaub ntawv kab, HDMI, RJ45, FPC, high zaus thawj chav kawm khoom

yog tsim rau tsis siv neeg soldering tshuab.

Optoelectronics kev lag luam: coj zaub, coj sawb, coj rectifier, coj pob teeb, coj teeb hlaws thiab lwm yam khoom

muaj feem xyuam rau lub tshuab tsis siv neeg soldering.

Kev lag luam khoom siv: cua txias chaw taws teeb tswj, cua txias tswj vaj huam sib luag, lub computer hais lus, TV hloov

connectors thiab lwm yam khoom yog haum rau tsis siv neeg soldering tshuab.

Automotive kev lag luam: ignition keyboards, automotive roj sensors, navigators, maus taus flash thiab lwm yam khoom

yog tsim rau tsis siv neeg soldering tshuab.

Kev lag luam khoom ua si: Cov khoom ua si kov cov khoom sib txuas, Circuit Court boards thiab lwm yam khoom tsim nyog rau kev siv lub tshuab tsis siv neeg.

4. Yeeb yaj duab

6.Certificate ntawm Tsis Siv Neeg PCB Soldering Tshuab

![]()

7. Kev xa khoom xa tuaj

DHL / TNT / FEDEX. Yog tias koj xav tau lwm lub sijhawm shipping, thov qhia rau peb. Peb yuav txhawb koj.

8. Cov nqe lus them nqi

Hloov chaw hauv txhab nyiaj, Western Union, Credit Card.

Thov qhia rau peb yog tias koj xav tau lwm yam kev txhawb nqa.

Zoo siab txais tos cov neeg ua lag luam los ntawm thoob plaws lub ntiaj teb. Txais tos tiv tauj peb!

9. Muaj kev paub txog

Vuam, tseem hu ua welding, splicing, yog txheej txheem tsim thiab cov txheej txheem rau kev koom nrog cov hlau lossis lwm yam thermoplastic.

cov ntaub ntawv xws li plastics nyob rau hauv ib tug rhuab, elevated los yog siab siab yam. Vuam yog ua tiav los ntawm peb txoj kev hauv qab no:

1. Fusion welding - cua sov lub workpiece yuav tsum tau koom rau ib nrab yaj nws los ua ib tug molten pas dej ua ke. Tom qab lub pas dej molten yog txiasthiab solidified, nws yog koom. Yog tias tsim nyog, nws tuaj yeem muab ntxiv rau qhov muab tub lim. Nws yog tsim rau vuam ntawm ntau yam hlau thiab alloys. siab.

2, welding siab - vuam txheej txheem yuav tsum siv siab rau lub vuam, teej tug mus rau kev ua ntawm ntau yam hlau cov ntaub ntawv.thiab qee yam khoom siv hlau.

3. Brazing - Cov khoom siv hlau uas muaj qhov qis qis dua li cov khoom siv hauv paus yog siv los ua cov khoom siv brazing, thiab cov khoom siv hauv pausyog wetted los ntawm cov khoom siv kua brazing, qhov sib koom ua ke sib koom ua ke, thiab cov khoom siv hlau niam txiv yog sib koom ua ke kom paub qhov txuasvuam. Haum rau vuam ntawm ntau yam ntaub ntawv, kuj haum rau vuam sib txawv hlau los yog cov ntaub ntawv sib txawv.

Muaj ntau qhov chaw ntawm lub zog rau kev vuam niaj hnub, nrog rau cov nplaim taws, arcs, lasers, electron beams, kev sib txhuam, thiab ultrasonics. HauvNtxiv nrog rau kev siv hauv lub Hoobkas, vuam kuj tseem tuaj yeem nqa tawm hauv ntau qhov chaw, xws li hauv hav zoov, hauv qab dej.thiab hauv qhov chaw. Vuam tuaj yeem ua rau muaj kev phom sij rau tus neeg teb xov tooj txhua qhov chaw, yog li yuav tsum tau ceev faj kom raug thaum vuam. Ua tauKev puas tsuaj los ntawm kev vuam rau tib neeg lub cev muaj xws li kub hnyiab, hluav taws xob poob siab, pom kev tsis pom kev, nqus pa ntawm cov pa phem, ntau dhau.

ultraviolet hluav taws xob, thiab lwm yam.