Kub Cua Kov Screen SMD Rework Chaw Nres Tsheb

DH-B2 ua rau mounting thiab tshem tawm ntawm lub qhov-qhov thiab nto mount Cheebtsam yooj yim dua li niaj hnub benchtop txoj kev" thiab "tso thermal stresses vim kub txawv thaum lub sij hawm sib dhos thiab rework" thiab "ua kom lub mounting ntawm Ball Grid Arrays thiab lwm yam zais pin tej pob khoom ntawm qhov chaw.

Hauj lwm lawm

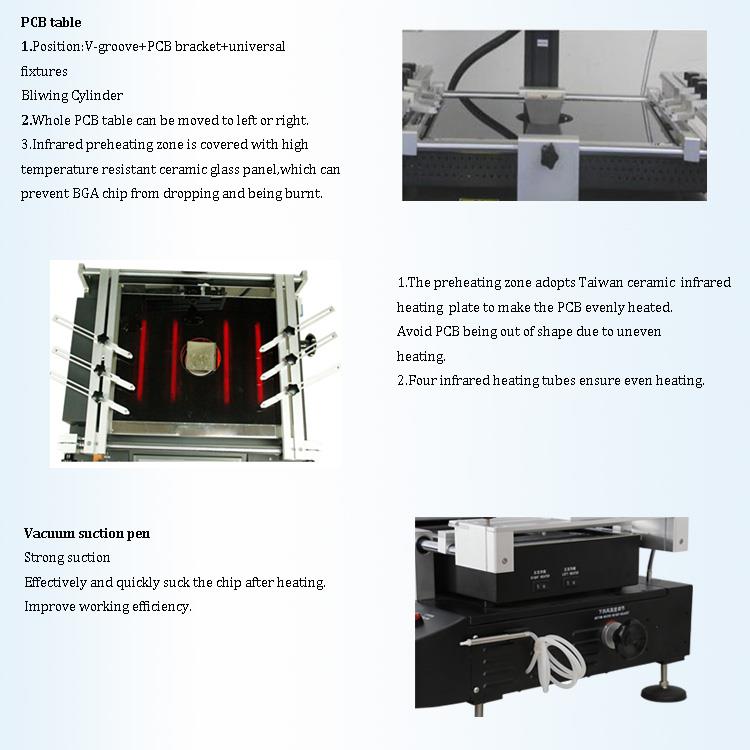

1. Khoom nta ntawm Kub Cua Kov Screen SMD Rework Chaw nres tsheb

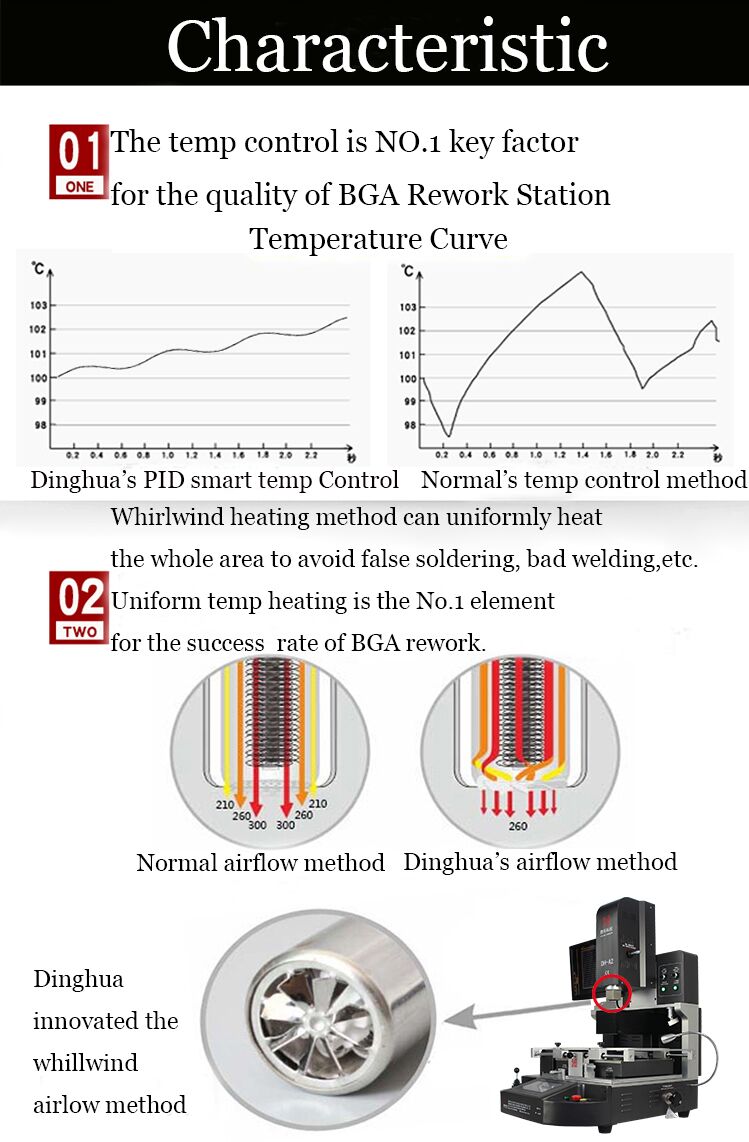

1.Qhov thib ib thiab thib ob qhov kub thiab txias cheeb tsam tuaj yeem teeb tsa 8 ntu (nce / nqis) temperatre profiles

thiab 8 qhov kub thiab txias profile. Thiab bga rework chaw nres tsheb tuaj yeem txuag tau 10 txhiab sib txawv

kub profiles toll.

2.Qhov thib peb yog preheating cheeb tsam los xyuas kom meej lub PCB tau tag nrho cov cua sov thaum lub sij hawm reworking txheej txheem.

3.DH-B2 BGA Rework Chaw nres tsheb tuaj yeem txuas nrog lub khoos phis tawj nrog built-in PC RSS serial chaw nres nkoj thiab

los nrog software CD

4.Qhov kub profiles rau sab saum toj thiab hauv qab cua sov yog mus ntawm nws tus kheej thaum DH-B2

BGA Rework Chaw nres tsheb yog ua haujlwm, thiab tus kiv cua hla tuaj yeem pab ua kom txias rau PCBA sai sai

tiv thaiv qhov deformation ntawm PCBA tshwm sim.

2.Specification

| Hwj chim | 4800W |

| Lub tshuab cua sov sab saum toj | Hwj chim 800W |

| Hauv qab rhaub | Cua kub 1200W. Infrared 2700W |

| Fais fab mov | AC220V+10% 50/60Hz |

| Dimension | L800 * W900 * H750 hli |

| Qhov chaw | V-groove PCB kev them nyiaj yug. thiab nrog sab nraud universal fixture |

| Kev tswj qhov kub thiab txias | K hom thermocouple, kaw voj tswj, ywj siab cua sov |

| Temperature raug | ± 2 degree |

| PCB loj | Max 450 * 500 mm, Min 20 * 20 mm |

| Workbench fine-tuning | ± 15mm rau pem hauv ntej / rov qab, t15mm righVleft |

| BGAchip | 80 * 80-1 * 1 hli |

| Yam tsawg kawg ntawm nti sib nrug | 0.15 hli |

| Temp Sensor | 4 (yeem) |

| Tsis hnyav | 36kg ua |

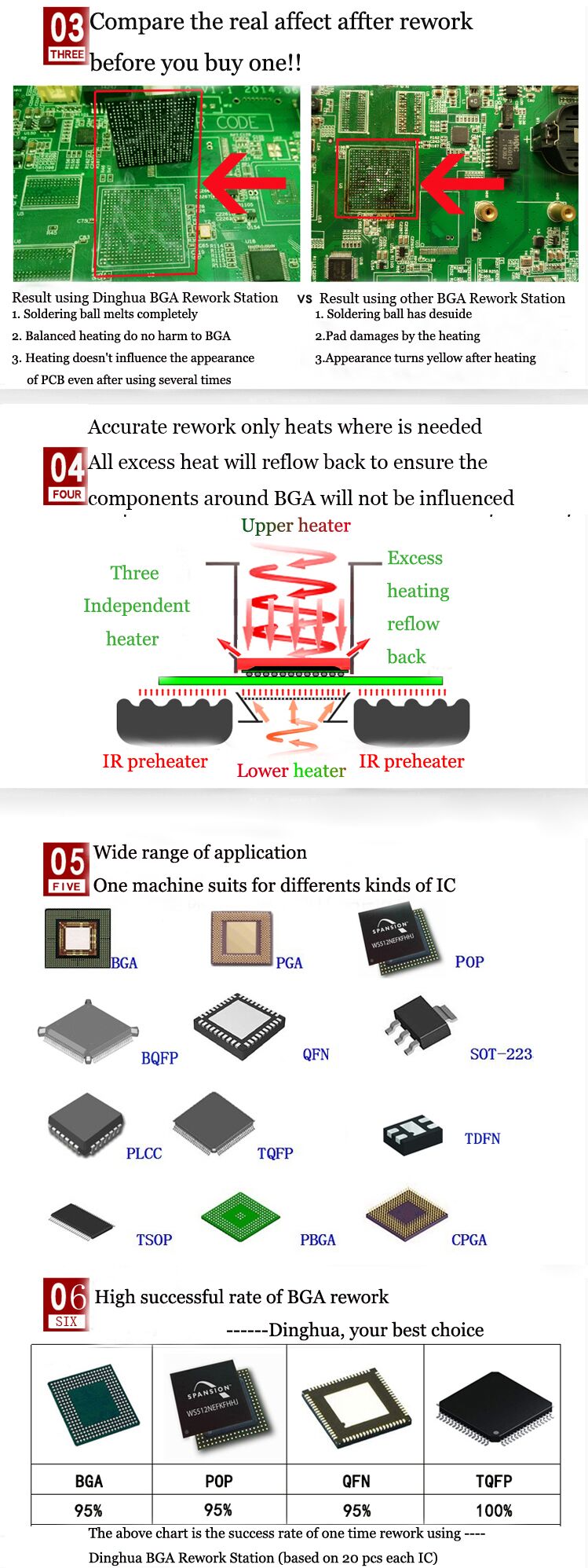

3.Cov ntsiab lus ntawm Kub Cua Kov Screen SMD Rework Chaw Nres Tsheb

1.HD kov npo interface;

2.Peb lub tshuab hluav taws xob ywj pheej ( cua kub & infrared );

3. Nqus cwj mem;

4.Led headlamp.

4.Vim li cas thiaj xaiv Peb Cov Cua Kub Kov Screen SMD Rework Chaw Nres Tsheb?

5. Daim ntawv pov thawj

6.Packing & Shipping ntawm Kub Cua Kov Screen SMD Rework Chaw nres tsheb

8.Kev paub txog

Kev ceev faj ntawm kev siv stencil

1. kev huv ntawm steel net

Vim li cas ntxuav stencils?

Guarantee solder paste luam ntawv

Khaws cov stencils zoo stripped

Txo cov ntawv luam tawm

Tsis txhob tipping, vau, thiab lwm yam misprints

Ceev faj:

1. Yuav kom cov stencil huv si, xyuas kom meej tias cov stencil tiv thaiv cov plua plav.

2. Lub stencil yuav tsum tau muab ntxuav tam sim ntawd tom qab siv kom tsis txhob muaj cov residual solder paste curing thiab nyuaj

tshem tawm.

3. Cov stencils yuav tsum muab tso rau ntawm ib lub txee rau siab thiab muab tso rau vertically. Cov phaj thiab daim hlau yuav tsum tau muab cais tawm

los ntawm ib leeg (tej zaum yuav ua yeeb yaj kiab), thiab kev sib tsoo thiab kev sib cuag yuav raug txwv. Rau stencils uas

tab tom tos kom ntxuav, lawv yuav tsum tsis txhob muab tso rau random kom tsis txhob muaj kev puas tsuaj.

2. Thaum cov kev txawv txav hauv qab no tshwm sim, cov stencil uas tau npaj tshiab yuav tsum tau hloov thiab ntxuav cov stencil qub.

1. Lub kaw lus qhib lub qhov cub tawg dhau lub sijhawm siv tau;

2. Cov stencil tau siv rau 8 teev;

3. Hlau mesh plugging (batch ntau lawm tsis xws luag "tsis tiav solder paste printing");

3. steel net tu txoj kev

1. Online: Tsis siv neeg so txhua 5 daim;

2. Off-line hom: tes so, phau ntawv tu nrog cawv nyob rau hauv lub teeb;

3. Offline: ultrasonic tu khoom;

4. kev ntsuas nruj ntawm steel net

1. Lub stencil yuav tsum tau kuaj kom nruj tom qab txhua qhov kev ntxuav tawm;

2. Ntsuas tsawg kawg tsib lub ntsiab lus ntawm qhov nro (plaub lub kaum sab xis + nruab nrab cov ntsiab lus);

3 nro feem ntau ntau dua 30N;

5.kev tswj cov stencils

1.Lub neej kev pab cuam ntawm stencils yuav tsum tau teev thiab saib xyuas kom zoo. Stencils uas tshaj

lub neej kev pabcuam yuav tsum tau muab pov tseg. Nws yog txwv tsis pub siv stencils rau kev siv txuas ntxiv. (feem ntau yog 100,000 zaug)

2. Txhua tus stencil yuav tsum tau suav thiab qhia meej cov khoom uas tuaj yeem siv tau rau ib stencil.

3. Txhua tus stencil yuav tsum tau lav tias muaj cov khoom seem kom nws tuaj yeem hloov tau sai thaum muaj

Qhov xwm txheej txawv txav tshwm sim.

6.Qhov cuam tshuam ntawm steel mesh ntawm solder paste printing

Lub thickness ntawm cov stencil thiab qhov qhib loj ntawm cov hlau mesh txiav txim siab npaum li cas ntawm cov tshuaj muab tshuaj los ua

luam tawm. Cov tshuaj nplaum ntau dhau yuav ua rau kev sib txuas. Tsawg solder paste yuav ua rau tsis txaus solder lossis ina-

tsis siv neeg solder. Cov duab ntawm qhov qhib ntawm cov hlau mesh thiab smoothness ntawm phab ntsa ntawm cov hlau mesh

kuj cuam tshuam qhov zoo ntawm stripping ntawm solder paste.